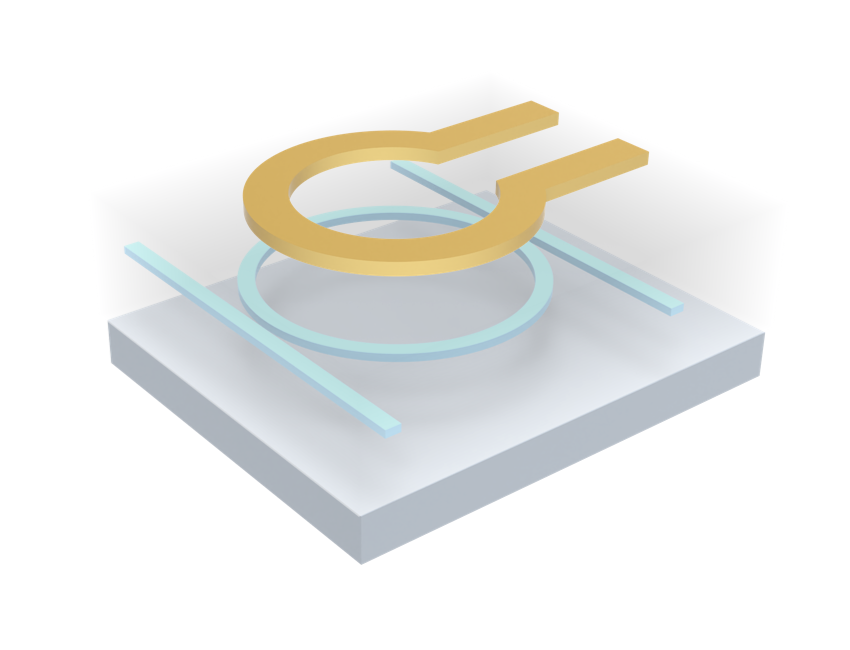

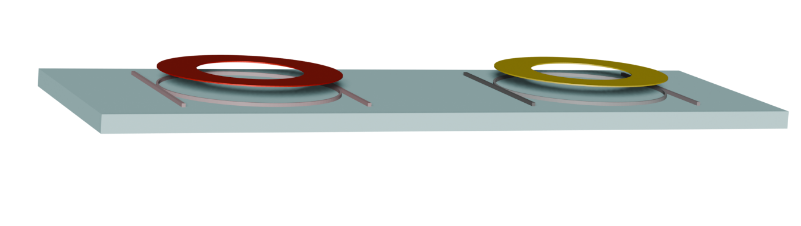

In this example, we simulate a silicon–organic hybrid (SOH) electro-optic modulator that overcomes the intrinsic limitations of silicon for efficient electro-optic modulation by using an organic material with a strong Pockels effect inside a slot waveguide. The device concept follows Heiner Zwickel et al., “Silicon-organic hybrid (SOH) modulators for intensity-modulation/direct-detection links with line rates of up to 120 Gbit/s,” Optics Express 25, 23784 (2017). DOI: 10.1364/OE.25.023784.

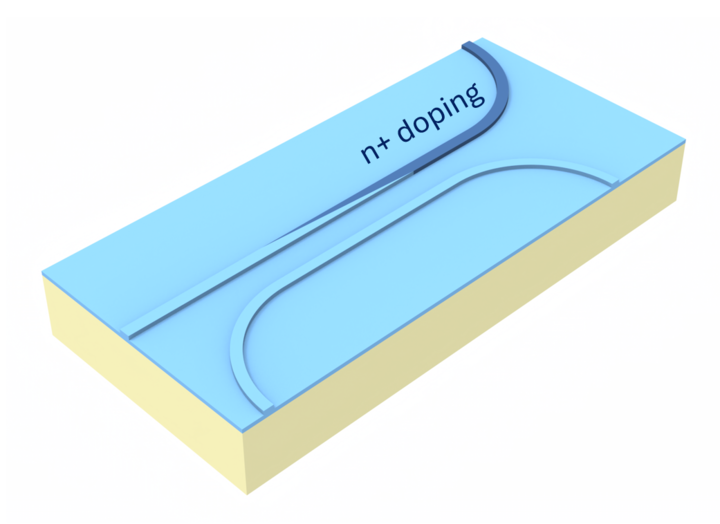

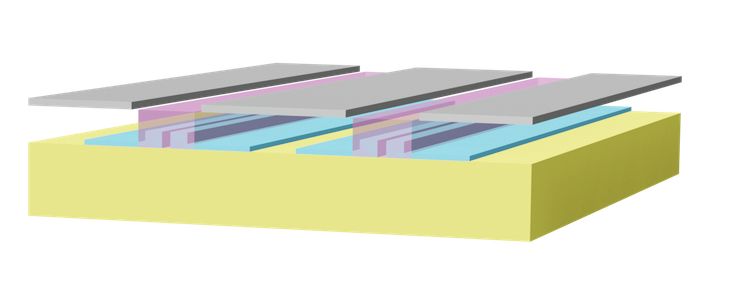

We build a full cross-section of a ground–signal–ground (GSG) transmission line integrated with a silicon slot waveguide filled with an organic electro-optic material. The RF field from the electrodes modulates the refractive index in the slot through the Pockels effect, which in turn changes the optical effective index.

Finally, we compute the electro-optic response and extract the Vπ·L figure of merit from the voltage-dependent change in effective index.

Workflow Overview¶

1) Define the full device geometry, including the silicon slot waveguide, organic cladding in the slot, oxide layers, and GSG metal transmission line.

2) Run an RF mode simulation of the transmission line to obtain the electric field distribution and normalize it to the applied voltage using current and voltage integrals.

3) Create and run the optical mode simulation.

4) Use the RF field to compute the Pockels-induced refractive index perturbation in the organic material, solve the optical modes of the perturbed waveguide, and extract Vπ·L from the change in optical effective index versus voltage.

import numpy as np

import tidy3d as td

import tidy3d.rf as rf

from matplotlib import pyplot as plt

from tidy3d import web

from tidy3d.plugins.mode import ModeSolver

Simulation Setup ¶

First, we will define an auxiliary function to help create the geometry.

def stack_box(

structure_1,

structure_2,

plane="x",

horizontal="right",

vertical="top",

gap_h=0,

gap_v=0,

new_name=None,

):

"""

Align and stack ``structure_2`` relative to ``structure_1`` within a given plane.

The function translates ``structure_2`` so that it is positioned next to

``structure_1`` according to the selected plane and alignment options.

Parameters

----------

structure_1 : tidy3d.Structure or geometry with bounding_box

Base object used as the alignment reference.

structure_2 : tidy3d.Structure or geometry with bounding_box

Object to be translated and stacked relative to ``structure_1``.

plane : {'x', 'y', 'z'}, optional

Plane normal along which stacking is defined. Default is ``'x'``.

horizontal : {'left', 'right', 'center'}, optional

Horizontal alignment relative to ``structure_1`` in the chosen plane.

Default is ``'right'``.

vertical : {'top', 'bottom', 'center'}, optional

Vertical alignment relative to ``structure_1`` in the chosen plane.

Default is ``'top'``.

gap_h : float, optional

Gap applied along the horizontal direction. Default is 0.

gap_v : float, optional

Gap applied along the vertical direction. Default is 0.

new_name : str, optional

Name for the updated ``structure_2``. If ``None``, the original name is kept.

Returns

-------

tidy3d.Structure or geometry

A translated copy of ``structure_2`` aligned to the new position.

"""

if isinstance(structure_1, td.Structure):

box_1 = structure_1.geometry.bounding_box

else:

box_1 = structure_1.bounding_box

if isinstance(structure_2, td.Structure):

box_2 = structure_2.geometry.bounding_box

else:

box_2 = structure_2.bounding_box

c1 = np.array(box_1.center)

c2 = np.array(box_2.center)

s1 = np.array(box_1.size)

s2 = np.array(box_2.size)

# Start from the center of structure_1

new_center = c1.copy()

# Axis normal to the stacking plane

axis = {"x": 0, "y": 1, "z": 2}[plane]

aux = [0, 1, 2]

aux.remove(axis)

horizontal_axis = min(aux)

vertical_axis = max(aux)

for align, ax, gap in [

(horizontal, horizontal_axis, gap_h),

(vertical, vertical_axis, gap_v),

]:

if align == "center":

new_center[ax] = c1[ax] + gap

elif align in ("right", "top"):

new_center[ax] = c1[ax] + s1[ax] / 2 + gap + s2[ax] / 2

elif align in ("left", "bottom"):

new_center[ax] = c1[ax] - s1[ax] / 2 - gap - s2[ax] / 2

else:

raise ValueError(f"Invalid alignment option: {align}")

dx = -c2[0] + new_center[0]

dy = -c2[1] + new_center[1]

dz = -c2[2] + new_center[2]

if isinstance(structure_2, td.Structure):

translated_geometry = structure_2.geometry.translated(x=dx, y=dy, z=dz)

return structure_2.updated_copy(

geometry=translated_geometry,

name=new_name if new_name else structure_2.name,

)

translated_geometry = structure_2.translated(x=dx, y=dy, z=dz)

return translated_geometry

Define Media¶

Next, we will define the material properties for both optical and RF frequencies.

# Material and spectral parameters

organic_index = 1.7

n_si = 3.45

n_sio2 = 1.44

# Define materials

organic = td.Medium(permittivity=organic_index**2)

silicon = td.Medium(permittivity=n_si**2)

oxide = td.Medium(permittivity=n_sio2**2)

# Metal material from library

metal = td.material_library["Al"]["Rakic1995"]

# Wavelength and frequency definitions

lda0 = 1.55

ldas = np.linspace(1.50, 1.60, 51)

freq0 = td.C_0 / lda0

freqs = td.C_0 / ldas

# RF material and spectral parameters

organic_index_RF = 1.7

# Define RF materials

organic_RF = td.Medium(permittivity=organic_index_RF**2)

silicon_RF = td.Medium(permittivity=11.7)

oxide_RF = td.Medium(permittivity=3.9)

# RF metal model

metal_rf = td.LossyMetalMedium(

frequency_range=(100000000.0, 100000000000.0),

conductivity=41,

fit_param=td.SurfaceImpedanceFitterParam(

max_num_poles=16,

),

)

# RF frequency sampling

rf_freqs = np.linspace(10e9, 90e9, 21)

Now, we will define some geometry parameters.

# Geometric parameters

eff_inf = 1e4

slot_width = 0.240

slot_height = 0.220

slot_separation = 0.120

rail_thickness = 0.070

rail_width = 1

substrate_thickness = 1

oxide_thickness = 1

clad_thickness = 0.5

cpw_gap = 1

cpw_thickness = 0.5

cpw_width = 2

organic_slot_width = cpw_gap * 0.8

Next, we define the necessary geometries and stack them to build the full device.

# Geometry primitives

si_substrate = td.Box.from_bounds(

rmin=(-eff_inf, -eff_inf, -eff_inf),

rmax=(eff_inf, eff_inf, substrate_thickness),

)

sio2_substrate = td.Box(center=(0, 0, 0), size=(eff_inf, eff_inf, oxide_thickness))

sio2_clad = td.Box(center=(0, 0, 0), size=(eff_inf, eff_inf, clad_thickness))

signal = td.Box(center=(0, 0, 0), size=(eff_inf, cpw_width, cpw_thickness))

ground = td.Box(center=(0, 0, 0), size=(eff_inf, eff_inf, cpw_thickness))

si_rail = td.Box(center=(0, 0, 0), size=(eff_inf, rail_width, rail_thickness))

slot_waveguide = td.Box(center=(0, 0, 0), size=(eff_inf, slot_width, slot_height))

organic_slot = td.Box(center=(0, 0, 0), size=(eff_inf, organic_slot_width, clad_thickness))

Finally, we combine all geometries and define the full structure.

# Stack geometries to build the full structure

sio2_substrate = stack_box(

si_substrate, sio2_substrate, plane="x", vertical="top", horizontal="center"

)

sio2_clad = stack_box(sio2_substrate, sio2_clad, plane="x", vertical="top", horizontal="center")

signal = stack_box(

sio2_clad,

signal,

plane="x",

vertical="top",

horizontal="center",

new_name="signal",

)

ground_left = stack_box(

signal,

ground,

plane="x",

vertical="center",

horizontal="left",

gap_h=cpw_gap,

new_name="ground_left",

)

ground_right = stack_box(

signal,

ground,

plane="x",

vertical="center",

horizontal="right",

gap_h=cpw_gap,

new_name="ground_right",

)

center_gap = cpw_gap / 2 + cpw_width / 2

slot_waveguide_left = stack_box(

sio2_substrate,

slot_waveguide,

plane="x",

vertical="top",

horizontal="center",

gap_h=-slot_separation / 2 - slot_width / 2 - center_gap,

new_name="slot_waveguide_left",

)

slot_waveguide_right = stack_box(

sio2_substrate,

slot_waveguide,

plane="x",

vertical="top",

horizontal="center",

gap_h=slot_separation / 2 + slot_width / 2 - center_gap,

new_name="slot_waveguide_right",

)

organic_slot_left = stack_box(

sio2_substrate,

organic_slot,

plane="x",

vertical="top",

horizontal="center",

gap_h=-center_gap,

new_name="organic_slot_left",

)

si_rail_left = stack_box(

sio2_substrate,

si_rail,

plane="x",

vertical="top",

horizontal="center",

gap_h=-slot_separation / 2 - slot_width / 2 - rail_width / 2 - center_gap,

new_name="si_rail",

)

si_rail_right = stack_box(

sio2_substrate,

si_rail,

plane="x",

vertical="top",

horizontal="center",

gap_h=slot_separation / 2 + slot_width / 2 + rail_width / 2 - center_gap,

new_name="si_rail_right",

)

# Mirror the organic slot to the opposite side

organic_slot_right = organic_slot_left.translated(x=0, y=2 * center_gap, z=0)

# Combine waveguide geometries

waveguide_left_geom = slot_waveguide_left + slot_waveguide_right + si_rail_left + si_rail_right

substrate = td.Structure(geometry=si_substrate, medium=silicon)

waveguide_right_geom = waveguide_left_geom.translated(x=0, y=2 * center_gap, z=0)

sio2 = td.Structure(geometry=sio2_substrate + sio2_clad, medium=oxide)

waveguide = td.Structure(geometry=waveguide_left_geom + waveguide_right_geom, medium=silicon)

cpw = td.Structure(

geometry=signal + ground_left + ground_right,

medium=metal,

)

organic_fill = td.Structure(geometry=organic_slot_left + organic_slot_right, medium=organic)

We will now create two separate structure lists: one for the optical simulation and one for the RF simulation.

# Structure collections for different simulation domains

structures_RF = [

substrate.updated_copy(medium=silicon_RF),

sio2.updated_copy(medium=oxide_RF),

cpw.updated_copy(medium=metal_rf),

organic_fill.updated_copy(medium=organic_RF),

waveguide.updated_copy(medium=silicon_RF),

]

structures_optical = [sio2, cpw, organic_fill, waveguide]

Finally, we place everything in a Scene object and visualize the final setup.

# Create and visualize the RF scene cross-section

scene = td.Scene(structures=structures_RF)

ax = scene.plot(x=0)

ax.set_xlim(-4, 4)

ax.set_ylim(0, 8)

plt.show()

RF Simulation ¶

Now we will define a Simulation object to calculate the RF modes.

First, we define a LayerRefinementSpec to refine the mesh around the metal structures and set the global mesh configuration, adding a MeshOverrideStructure to properly resolve the optical waveguide.

# Layer refinement around CPW structures

refinement = 10

lr_spec = td.LayerRefinementSpec.from_structures(

structures=[cpw],

min_steps_along_axis=5,

corner_refinement=td.GridRefinement(dl=cpw_thickness / refinement, num_cells=5),

refinement_inside_sim_only=False,

)

# Mesh override for the waveguide region (finer mesh in the z-direction)

mins, maxs = slot_waveguide_left.bounds

center_waveguide = 0.5 * (np.array(mins) + np.array(maxs))

override_region = td.MeshOverrideStructure(

geometry=td.Box(

size=(eff_inf, slot_width, slot_height),

center=(0, -center_gap, center_waveguide[2]),

),

dl=(None, 0.02, 0.02),

)

# Global grid specification for the RF simulation

grid_spec_RF = td.GridSpec.auto(

min_steps_per_sim_size=150,

wavelength=td.C_0 / max(rf_freqs),

layer_refinement_specs=[lr_spec],

override_structures=[override_region],

)

Next, we will define an auxiliary function to correctly place the integral paths for calculating impedance and voltage.

def add_gsg_integrals(ground_left, signal, ground_right, plane="x"):

"""

Create current and voltage integrals for a GSG (ground-signal-ground) CPW cross-section.

Parameters

----------

ground_left : tidy3d.Structure or geometry

Left ground conductor.

signal : tidy3d.Structure or geometry

Signal conductor.

ground_right : tidy3d.Structure or geometry

Right ground conductor.

plane : {'x', 'y', 'z'}, optional

Normal axis of the cross-sectional plane. Default is ``'x'``.

Returns

-------

tuple

(I_int, V_int) current and voltage integral objects.

"""

# Extract geometries if structures are provided

if isinstance(ground_left, td.Structure):

ground_left_geom = ground_left.geometry

else:

ground_left_geom = ground_left

if isinstance(signal, td.Structure):

signal_geom = signal.geometry

else:

signal_geom = signal

# Determine in-plane axes

axis = {"x": 0, "y": 1, "z": 2}[plane]

aux = [0, 1, 2]

aux.remove(axis)

horizontal_axis = min(aux)

vertical_axis = max(aux)

gap = signal_geom.bounds[0][horizontal_axis] - ground_left_geom.bounds[1][horizontal_axis]

height = signal_geom.bounding_box.size[vertical_axis] * 2

width = signal_geom.bounding_box.size[horizontal_axis] + gap

# Current integration loop around the signal conductor

I_int = rf.AxisAlignedCurrentIntegral(

center=signal_geom.bounding_box.center,

size=(

0,

width,

height,

),

sign="+",

)

center_gap = list(signal_geom.bounding_box.center)

center_gap[horizontal_axis] = signal_geom.bounds[1][horizontal_axis] + gap / 2

size = [0, 0, 0]

size[horizontal_axis] = gap

# Voltage integration path from signal to ground

V_int = rf.AxisAlignedVoltageIntegral(

center=center_gap,

size=size,

sign="-",

)

return I_int, V_int

I_int, V_int = add_gsg_integrals(ground_left, signal, ground_right)

We can now define our Simulation object and visualize the setup.

# RF simulation setup

sim_RF = td.Simulation(

grid_spec=grid_spec_RF,

structures=structures_RF,

center=signal.bounding_box.center,

size=(10, 100, 100),

run_time=1e-12,

)

# RF mode solver configuration

mode_RF = ModeSolver(

simulation=sim_RF,

plane=td.Box(

center=signal.bounding_box.center,

size=(0, 100, 100),

),

mode_spec=td.ModeSpec(num_modes=10, target_neff=1.5),

freqs=[rf_freqs[5]],

)

# Plot modes and grid

ax = mode_RF.plot()

mode_RF.plot_grid(ax=ax)

ax.set_xlim(-3, 0)

ax.set_ylim(0, 5)

plt.show()

18:53:41 -03 WARNING: RF simulations and functionality will require new license requirements in an upcoming release. All RF-specific classes are now available within the sub-package 'tidy3d.rf'. - Contains a 'LossyMetalMedium'.

We can also visualize the integral paths to ensure they are defined correctly.

# Plot voltage and current integration paths

fig, ax = plt.subplots(figsize=(10, 3))

mode_RF.plot(ax=ax)

I_int.plot(x=0, ax=ax)

V_int.plot(x=0, ax=ax)

ax.set_xlim(-5, 5)

ax.set_ylim(0, 5)

plt.show()

Finally, we can run the RF mode solver and process the data.

# Run the RF mode solver simulation

data_RF = web.run(mode_RF, task_name="mode_solver_RF")

18:53:43 -03 Created task 'mode_solver_RF' with resource_id 'mo-3c7ac757-adb0-4f3f-a086-fa1be7189e7c' and task_type 'MODE_SOLVER'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-3c7ac757-adb0- 4f3f-a086-fa1be7189e7c'.

Task folder: 'default'.

Output()

18:53:46 -03 Estimated FlexCredit cost: 0.007. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

18:53:49 -03 status = success

Output()

18:54:00 -03 Loading simulation from simulation_data.hdf5

First, we can visualize the RF fields and inspect their overlap with the optical waveguide.

# Plot the magnitude of the Ey field for the first mode

ax = mode_RF.plot_field("Ey", "abs", mode_index=0, robust=False, vmax=15, shading="gouraud")

ax.set_xlim(0.5, 2.5)

ax.set_ylim(1.5, 4.5)

plt.show()

WARNING: RF simulations and functionality will require new license requirements in an upcoming release. All RF-specific classes are now available within the sub-package 'tidy3d.rf'. - Contains a 'LossyMetalMedium'. - Contains monitors defined for RF wavelengths.

Optical Simulation ¶

Next, we define an optical simulation and solve for the propagating mode.

# Simulation domain, sources, and monitors

sim_size = (10, 10, 5)

sim_center = (0, 0, 4)

half_z = 0.5 * sim_size[2]

substrate_thickness = 2.0

substrate_center_z = -half_z + substrate_thickness / 2

substrate_geom = td.Box(

center=(0, 0, substrate_center_z),

size=(sim_size[0], sim_size[1], substrate_thickness),

)

substrate = td.Structure(geometry=substrate_geom, medium=oxide, name="substrate")

# Optical grid specification

grid_spec = td.GridSpec.auto(

min_steps_per_wvl=50,

override_structures=[],

wavelength=1.55,

)

mode_spec = td.ModeSpec(num_modes=1, target_neff=organic_index)

source_span_y = max(slot_width, 4 * rail_width)

source_span_z = 3 * slot_height

# Field monitor in a cross-sectional plane

field_monitor = td.FieldMonitor(

center=(0, 0, 0),

size=(0, sim_size[1], sim_size[2]),

freqs=[freq0],

name="field_slice",

)

simulation_optical = td.Simulation(

size=sim_size,

center=sim_center,

grid_spec=grid_spec,

structures=structures_optical,

sources=[],

monitors=[],

run_time=1e-12,

)

# Optical mode solver setup

mode_solver_center = (0, center_gap, center_waveguide[2])

mode_solver_size = (0, 3, 3)

ms = ModeSolver(

simulation=simulation_optical,

plane=td.Box(

center=mode_solver_center,

size=mode_solver_size,

),

mode_spec=td.ModeSpec(num_modes=2),

freqs=[freq0],

)

# Plot the computed modes

ms.plot()

plt.show()

# Run the optical mode solver simulation

mode_data = web.run(ms, task_name="mode_solver")

18:54:01 -03 Created task 'mode_solver' with resource_id 'mo-34b3abf4-9dd0-490b-aec1-d385d5b8a9f8' and task_type 'MODE_SOLVER'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-34b3abf4-9dd0- 490b-aec1-d385d5b8a9f8'.

Task folder: 'default'.

Output()

18:54:04 -03 Estimated FlexCredit cost: 0.013. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

18:54:06 -03 status = success

Output()

18:54:16 -03 Loading simulation from simulation_data.hdf5

# Plot the magnitude of the Ey field for the first optical mode

ax = ms.plot_field("Ey", "abs", mode_index=0, robust=False)

plt.show()

Pockels Effect Calculation ¶

Now that we have the optical simulation and the RF fields, we can perturb the optical simulation by considering the Pockels effect.

We first normalize the RF fields by the voltage, use the formula for the Pockels effect

$$-0.5 n_0^3 r_{33} E$$

and create a perturbed medium for the polymer extraordinary axis using a CustomAnisotropicMedium object.

Finally, we scale it for different voltages.

def perturbed_solver(Voltage, absolute=True):

"""

Build a perturbed optical simulation and mode solver under an applied voltage.

The refractive index of the organic region is modified using the

electro-optic effect based on the RF electric field distribution.

Parameters

----------

Voltage : float

Applied voltage used to scale the refractive index perturbation.

absolute : bool, optional

If True, use the magnitude of the RF electric field. If False,

use the real part. Default is True.

Returns

-------

tuple

(perturbed_sim, perturbed_mode_solver)

"""

e_field = data_RF.Ey

V0 = abs(V_int.compute_voltage(data_RF).sel(mode_index=0).isel(f=0, drop=True))

r33 = 144e-6 # µm/V

n0 = 1.7

if absolute:

e_norm = (e_field / V0.real).isel(mode_index=0, f=0, drop=True).abs

else:

e_norm = (e_field / V0.real).isel(mode_index=0, f=0, drop=True).real

delta_n = -0.5 * n0**3 * r33 * e_norm

eps_o_array = td.SpatialDataArray(

np.full((1, 1, 1), n0**2), coords={"x": [0], "y": [0], "z": [0]}

)

eps_e_array = (n0 + delta_n * Voltage) ** 2

perturbed_medium = td.CustomAnisotropicMedium(

xx=td.CustomMedium(permittivity=eps_o_array, subpixel=True),

yy=td.CustomMedium(permittivity=eps_e_array, subpixel=True),

zz=td.CustomMedium(permittivity=eps_o_array, subpixel=True),

)

perturbed_organic_fill = organic_fill.updated_copy(medium=perturbed_medium)

perturbed_sim = simulation_optical.updated_copy(

structures=[sio2, cpw, perturbed_organic_fill, waveguide]

)

perturbed_mode_solver = ModeSolver(

simulation=perturbed_sim,

plane=ms.plane,

mode_spec=td.ModeSpec(num_modes=1),

freqs=[freq0],

)

return perturbed_sim, perturbed_mode_solver

Calculating $V_\pi$¶

To calculate $V_\pi$, we create a batch of simulations for different voltages.

# Run perturbed mode solvers for a range of applied voltages

voltages = np.arange(11)

sims = {str(v): perturbed_solver(v)[1] for v in voltages}

perturbed_data = web.run(

sims,

task_name="perturbed_mode_solver",

reduce_simulation=True,

)

Output()

18:54:28 -03 Started working on Batch containing 11 tasks.

18:54:47 -03 Maximum FlexCredit cost: 0.115 for the whole batch.

Use 'Batch.real_cost()' to get the billed FlexCredit cost after completion.

Output()

18:55:16 -03 Batch complete.

# Extract effective index for the fundamental mode at each voltage

n_eff = [sim_data.n_eff.isel(mode_index=0, f=0).item() for sim_data in perturbed_data.values()]

# Plot effective index versus applied voltage

_ = plt.plot(voltages, n_eff, ".-")

_ = plt.ticklabel_format(style="plain", useOffset=False)

plt.gca().set(xlabel="Voltage (V)", ylabel="Optical Effective Index")

plt.show()

# The variation is approximately linear, so use the full voltage range

dneff_dV = abs(n_eff[-1] - n_eff[0]) / (voltages[-1] - voltages[0])

vpil = 0.5 * 1.55 / dneff_dV # V·µm

print(f"Vπ·L (push-pull) = {vpil * 1e-4 / 2:.2f} V·cm")

Vπ·L (push-pull) = 0.48 V·cm