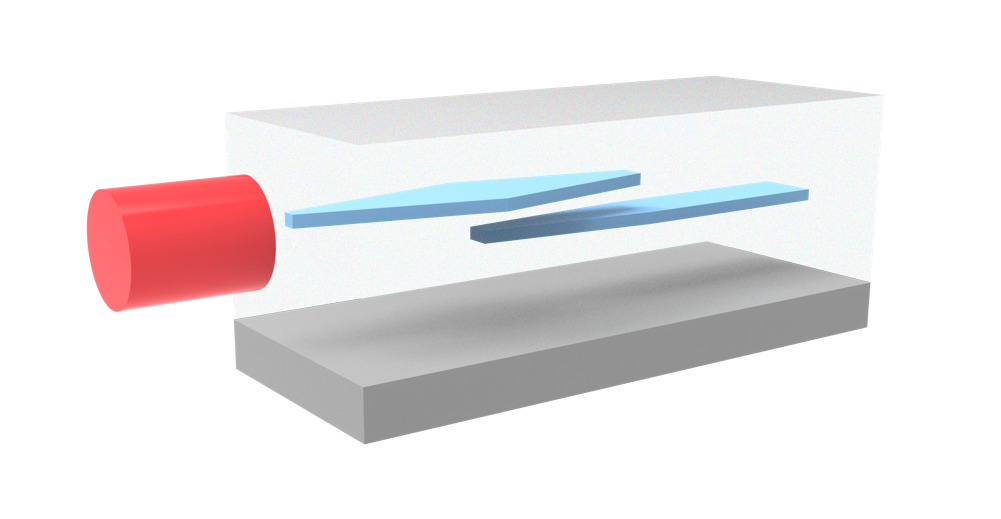

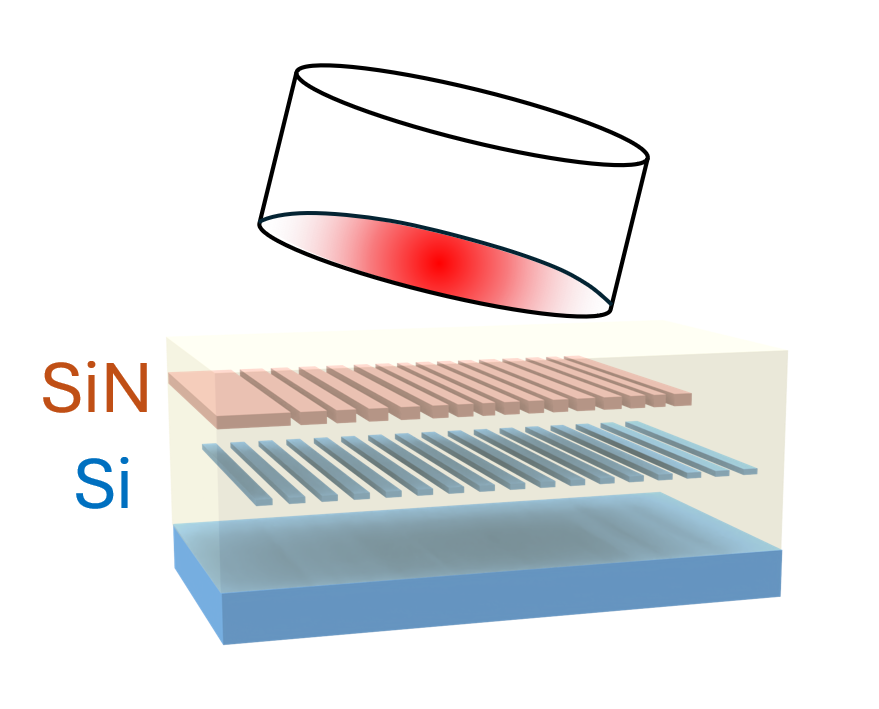

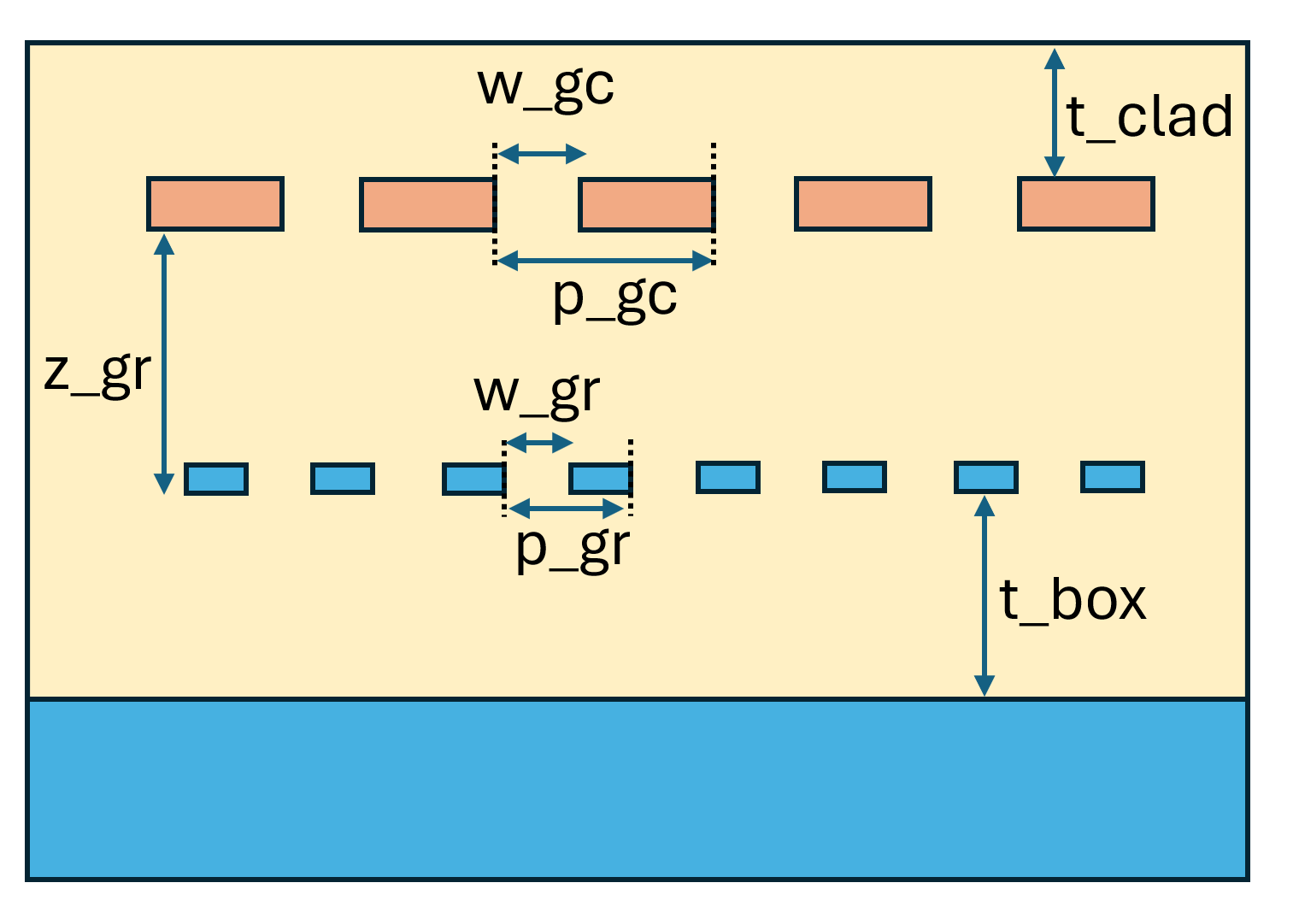

Silicon nitride has attracted increasing interest due to its superior passive properties. However, similar to silicon PICs, fiber-to-chip coupling remains a significant challenge for SiN platforms. Conventional SiN grating couplers exhibit low coupling efficiency due to their low refractive index contrast. To address this, a high-contrast grating reflector (GR) is employed as a bottom reflector to enhance coupling efficiency, rather than using distributed Bragg reflectors (DBR) or metal reflectors. Through design optimization, combining parameter sweeps and adjoint-based inverse design, a grating coupler with high coupling efficiency (< 1 dB) is achieved.

The workflow includes:

- Periodic SiN Grating Coupler Design: Optimizing the SiN grating period, gap size, and fiber position.

- Silicon Grating Reflector Design: Designing a bottom silicon grating to reflect leakage light upwards.

- Interlayer Distance Optimization: Tuning the distance between the SiN and Si layers.

- Inverse Design: Using adjoint optimization to apodize the grating for maximum efficiency.

The design is based on the following publication: Jinghui Zou, Yu Yu, Mengyuan Ye, Lei Liu, Shupeng Deng, and Xinliang Zhang, "Ultra efficient silicon nitride grating coupler with bottom grating reflector," Opt. Express 23, 26305-26312 (2015). DOI: 10.1364/OE.23.026305.

import autograd as ag

import autograd.numpy as np

import matplotlib.pyplot as plt

import optax

import tidy3d as td

import tidy3d.plugins.design as tdd

import tidy3d.web as web

Simulation Setup¶

We define the central wavelength, frequency, and bandwidth for the simulation. The simulation will target 1550 nm.

lda0 = 1.55 # Central wavelength

freq0 = td.C_0 / lda0 # Central frequency

ldas = np.linspace(1.5, 1.6, 101) # Wavelength range

freqs = td.C_0 / ldas

fwidth = 0.5 * (np.max(freqs) - np.min(freqs)) # Frequency width of the source

We define the relevant materials as nondispersive mediums for simplicity.

SiN = td.Medium.from_nk(n=1.97, k=0, freq=freq0)

Si = td.Medium.from_nk(n=3.47, k=0, freq=freq0)

SiO2 = td.Medium.from_nk(n=1.44, k=0, freq=freq0)

Defining the fixed geometric parameters.

t_SiN = 0.4 # Thickness of SiN layer

t_Si = 0.22 # Thickness of Silicon waveguide

t_clad = 0.75 # Target cladding thickness

t_box = 2 # Thickness of Buried Oxide (BOX)

theta = np.deg2rad(8) # Fiber angle

mfd = 10.4 # Mode field diameter

n_gc = 14 # Number of SiN grating teeth

inf_eff = 1e3 # Effective infinity

Next we define some fixed simulation parameters. These will be used repeatedly in various following simulation setups.

run_time = 3e-12 # Simulation run time

# Grid specification

grid_spec = td.GridSpec.auto(min_steps_per_wvl=20)

# Boundary condition specification

boundary_spec = td.BoundarySpec(

x=td.Boundary.absorber(num_layers=80),

y=td.Boundary.periodic(), # set the boundary to periodic in y since it's a 2D simulation

z=td.Boundary.pml(),

)

# Mode monitor for coupling efficiency measurement

mode_monitor = td.ModeMonitor(

center=(-lda0 / 2, 0, t_SiN / 2),

size=(0, td.inf, 5 * t_SiN),

freqs=freqs,

mode_spec=td.ModeSpec(num_modes=1, target_neff=1.97),

name="mode",

)

Periodic SiN Grating Coupler Design¶

In the first part, we design and optimize a periodic SiN grating coupler by parameter sweeping the grating period, duty cycle, and fiber position.

Since we are optimizing the grating only, we will ignore the silicon layer as well as the substrate for now. They will be added and optimized later.

def make_2D_SiN_grating(w_gc: float, p_gc: float) -> td.Structure:

"""

Creates a 2D SiN grating structure.

Parameters:

w_gc (float): Width of the etched region.

p_gc (float): Period of the grating.

Returns:

td.Structure: The resulting grating structure.

"""

gratings = 0

# Iterate to create each period of the grating

for i in range(n_gc):

# Add a box for each grating period

gratings += td.Box.from_bounds(

rmin=(w_gc + i * p_gc, -inf_eff, 0), rmax=((i + 1) * p_gc, inf_eff, t_SiN)

)

return td.Structure(geometry=gratings, medium=SiN)

waveguide = td.Structure(

geometry=td.Box.from_bounds(rmin=(-inf_eff, -inf_eff, 0), rmax=(0, inf_eff, t_SiN)),

medium=SiN,

)

oxide_layer = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-inf_eff, -inf_eff, -inf_eff), rmax=(inf_eff, inf_eff, t_SiN + t_clad)

),

medium=SiO2,

)

def make_2D_SiN_grating_sim(w_gc: float, p_gc: float, x_fiber: float) -> td.Simulation:

"""

Creates a simulation for a 2D SiN grating coupler.

Parameters:

w_gc (float): Width of the etched region.

p_gc (float): Period of the grating.

x_fiber (float): x-position of the fiber center.

Returns:

td.Simulation: The Tidy3D simulation object.

"""

gratings = make_2D_SiN_grating(w_gc, p_gc) # Create the grating structure

# Create a Gaussian beam source representing the input fiber mode

gaussian_beam = td.GaussianBeam(

center=(x_fiber, 0, t_SiN + t_clad + lda0 / 4),

size=(2 * mfd, td.inf, 0),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

pol_angle=np.pi / 2,

angle_theta=theta,

angle_phi=0,

direction="-",

waist_radius=mfd / 2,

waist_distance=0,

)

# Simulation domain box

sim_box = td.Box.from_bounds(

rmin=(-lda0, 0, -lda0), rmax=(n_gc * p_gc + lda0, 0, t_SiN + t_clad + lda0)

)

# Create the simulation

sim = td.Simulation(

center=sim_box.center,

size=sim_box.size,

grid_spec=grid_spec,

run_time=run_time,

structures=[oxide_layer, gratings, waveguide],

sources=[gaussian_beam],

monitors=[mode_monitor],

boundary_spec=boundary_spec,

)

return sim

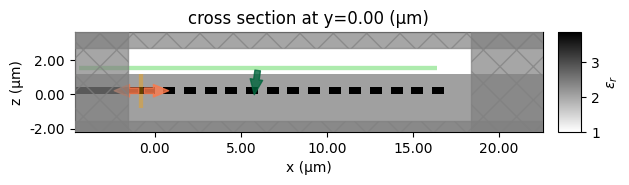

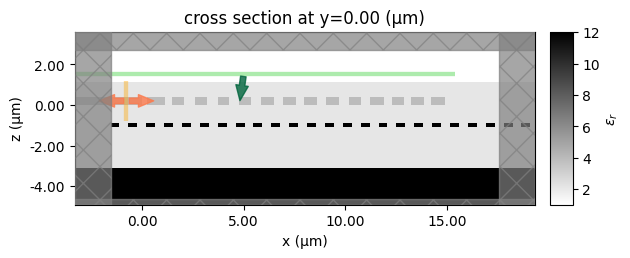

Create a single simulation to verify the setup and visualize the permittivity distribution.

sim = make_2D_SiN_grating_sim(w_gc=0.5, p_gc=1.2, x_fiber=6)

sim.plot_eps(y=0)

plt.show()

def coupling_efficiency(sim_data: td.SimulationData) -> dict:

"""

Calculates the coupling efficiency from simulation data.

Parameters

----------

sim_data : td.SimulationData

The simulation data containing mode amplitudes.

Returns

-------

dict

A dictionary containing the coupling efficiency in dB.

"""

# Extract the amplitude of the fundamental mode (mode_index=0) propagating in the backward direction ("-") at the central frequency (freq0)

amp = sim_data["mode"].amps.sel(mode_index=0, direction="-", f=freq0).values

return {"coupling efficiency": 20 * np.log10(np.abs(amp))}

Now we are ready to perform the parameter sweep (grid search) using Tidy3D's Design plugin.

# Define parameters and bounds

params = [

tdd.ParameterFloat(name="w_gc", span=(0.4, 0.5), num_points=6),

tdd.ParameterFloat(name="p_gc", span=(1.0, 1.2), num_points=6),

tdd.ParameterFloat(name="x_fiber", span=(4.8, 5.2), num_points=5),

]

# Design optimization method (grid search)

method = tdd.MethodGrid()

# Create a design space and run the sweep

design_space = tdd.DesignSpace(method=method, parameters=params, path_dir="./data")

results = design_space.run(make_2D_SiN_grating_sim, coupling_efficiency)

11:39:50 Eastern Standard Time Running 180 Simulations

After the sweep is done, we can pick the optimal design parameters.

df = results.to_dataframe() # Convert the results to a pandas DataFrame

# Pick the best design

best_row = df.loc[df["coupling efficiency"].idxmax()]

best_w_gc, best_p_gc, best_x_fiber = best_row[["w_gc", "p_gc", "x_fiber"]]

df.sort_values(by="coupling efficiency", ascending=False)

| w_gc | p_gc | x_fiber | coupling efficiency | |

|---|---|---|---|---|

| 72 | 0.44 | 1.08 | 5.0 | -5.882929 |

| 73 | 0.44 | 1.08 | 5.1 | -5.883616 |

| 71 | 0.44 | 1.08 | 4.9 | -5.884305 |

| 74 | 0.44 | 1.08 | 5.2 | -5.886312 |

| 70 | 0.44 | 1.08 | 4.8 | -5.887364 |

| ... | ... | ... | ... | ... |

| 150 | 0.40 | 1.20 | 4.8 | -24.129137 |

| 151 | 0.40 | 1.20 | 4.9 | -24.406663 |

| 152 | 0.40 | 1.20 | 5.0 | -24.685795 |

| 153 | 0.40 | 1.20 | 5.1 | -24.970030 |

| 154 | 0.40 | 1.20 | 5.2 | -25.254913 |

180 rows × 4 columns

Periodic Si Grating Reflector Design¶

To improve the coupling efficiency of the grating coupler, we add a bottom grating in the silicon layer to reflect leakage light upwards. We need to optimize the grating period and duty cycle to achieve maximum reflection.

def make_2D_Si_grating(w_gr: float, p_gr: float, z_gr: float) -> "td.Structure":

"""

Creates a 2D silicon grating structure.

Args:

w_gr: Width of the etched region.

p_gr: Period of the grating.

z_gr: The z-coordinate of the bottom surface of the grating.

Returns:

A Tidy3D Structure object representing the entire grating.

"""

offset = -2 # Initial offset for the grating placement

# Loop to create multiple grating teeth

gratings = 0

for i in range(50):

gratings += td.Box.from_bounds(

rmin=(offset + w_gr + i * p_gr, -inf_eff, -z_gr),

rmax=(offset + (i + 1) * p_gr, inf_eff, -z_gr + t_Si),

)

return td.Structure(geometry=gratings, medium=Si)

# Create a Gaussian beam at the optimal position

gaussian_beam = td.GaussianBeam(

center=(best_x_fiber, 0, t_SiN + t_clad + lda0 / 4),

size=(2 * mfd, td.inf, 0),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

pol_angle=np.pi / 2,

angle_theta=theta,

angle_phi=0,

direction="-",

waist_radius=mfd / 2,

waist_distance=0,

)

def make_2D_Si_grating_sim(w_gr: float, p_gr: float, z_gr: float = 1) -> "td.Simulation":

"""

Creates a Tidy3D simulation for a 2D silicon grating.

Args:

w_gr: Width of the etched region.

p_gr: Period of the grating.

z_gr: The z-coordinate of the bottom surface of the grating.

Returns:

A Tidy3D Simulation object.

"""

# Create the grating structure

gratings = make_2D_Si_grating(w_gr, p_gr, z_gr)

# Define the substrate structure

substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-inf_eff, -inf_eff, -inf_eff), rmax=(inf_eff, inf_eff, -z_gr - t_box)

),

medium=Si,

)

# Define a flux monitor to measure reflection

flux_monitor = td.FluxMonitor(

center=(0, 0, t_SiN + t_clad + lda0 / 2),

size=(td.inf, td.inf, 0),

freqs=[freq0],

normal_dir="+",

name="flux",

)

# Simulation domain box

sim_box = td.Box.from_bounds(

rmin=(-lda0, 0, -z_gr - t_box - lda0),

rmax=(20 * p_gr + lda0, 0, t_SiN + t_clad + lda0),

)

# Create the simulation

sim = td.Simulation(

center=sim_box.center,

size=sim_box.size,

grid_spec=grid_spec,

run_time=run_time,

structures=[oxide_layer, gratings, substrate],

sources=[gaussian_beam],

monitors=[flux_monitor],

boundary_spec=boundary_spec,

)

return sim

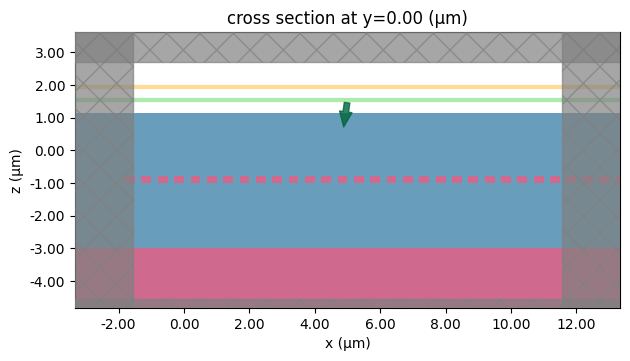

Visualize the simulation setup.

sim = make_2D_Si_grating_sim(w_gr=0.2, p_gr=0.5)

sim.plot(y=0)

plt.show()

def reflectivity(sim_data: td.SimulationData) -> dict:

"""

Extracts the reflectivity from the simulation data.

Parameters:

sim_data (td.SimulationData): The simulation data containing flux results.

Returns:

dict: A dictionary containing the reflectivity values.

"""

# Extract the flux values from the simulation data

r = sim_data["flux"].flux.values

return {"reflectivity": r}

Similar to the previous section, we will perform a parameter sweep to optimize the Si grating period and duty cycle.

# Design parameters and bounds

params = [

tdd.ParameterFloat(name="w_gr", span=(0.3, 0.5), num_points=11),

tdd.ParameterFloat(name="p_gr", span=(0.7, 1.0), num_points=11),

]

# Perform parameter sweep

design_space = tdd.DesignSpace(method=method, parameters=params, path_dir="./data")

results = design_space.run(make_2D_Si_grating_sim, reflectivity)

11:44:43 Eastern Standard Time Running 121 Simulations

From the results, we find the parameters that yield the highest reflection.

df = results.to_dataframe()

best_row = df.loc[df["reflectivity"].idxmax()]

best_w_gr, best_p_gr = best_row[["w_gr", "p_gr"]]

df.sort_values(by="reflectivity", ascending=False)

| w_gr | p_gr | reflectivity | |

|---|---|---|---|

| 73 | 0.44 | 0.88 | [0.9637354] |

| 74 | 0.46 | 0.88 | [0.95940167] |

| 59 | 0.38 | 0.85 | [0.95864624] |

| 75 | 0.48 | 0.88 | [0.94225246] |

| 87 | 0.50 | 0.91 | [0.93560386] |

| ... | ... | ... | ... |

| 113 | 0.36 | 1.00 | [0.20038801] |

| 99 | 0.30 | 0.97 | [0.19345635] |

| 112 | 0.34 | 1.00 | [0.18722352] |

| 111 | 0.32 | 1.00 | [0.17701866] |

| 110 | 0.30 | 1.00 | [0.16915095] |

121 rows × 3 columns

Interlayer Distance Optimization¶

Here we combine the optimized SiN grating and the optimized Si reflector into a single simulation and optimize the vertical separation z_gr to ensure constructive interference and therefore maximum coupling efficiency.

def make_2D_full_grating_sim(z_gr: float) -> td.Simulation:

"""

Creates a simulation of the full coupler structure including SiN and Si gratings.

Parameters

----------

z_gr : float

The z-position for the Si grating structure.

Returns

-------

td.Simulation

Tidy3D simulation object.

"""

# Create the SiN grating structure using optimal width and period

gratings_SiN = make_2D_SiN_grating(best_w_gc, best_p_gc)

# Create the Si grating structure using optimal width, period, and the given z-position

gratings_Si = make_2D_Si_grating(best_w_gr, best_p_gr, z_gr)

# Define the silicon substrate structure

substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-inf_eff, -inf_eff, -inf_eff), rmax=(inf_eff, inf_eff, -z_gr - t_box)

),

medium=Si,

)

# Calculate the SiN grating length

l = best_p_gc * n_gc

# Simulation domain box

sim_box = td.Box.from_bounds(

rmin=(-lda0, 0, -z_gr - t_box - lda0), rmax=(l + lda0, 0, t_SiN + t_clad + lda0)

)

# Construct the simulation object

sim = td.Simulation(

center=sim_box.center,

size=sim_box.size,

grid_spec=grid_spec,

run_time=run_time,

structures=[oxide_layer, gratings_SiN, gratings_Si, waveguide, substrate],

sources=[gaussian_beam],

monitors=[mode_monitor],

boundary_spec=boundary_spec,

)

return sim

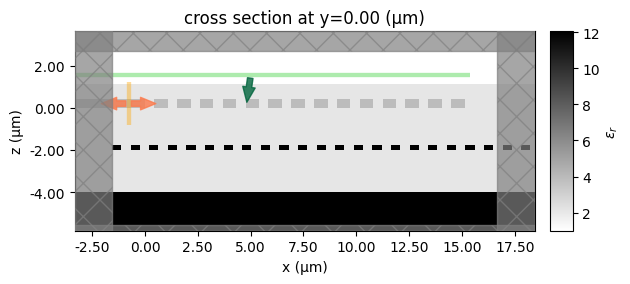

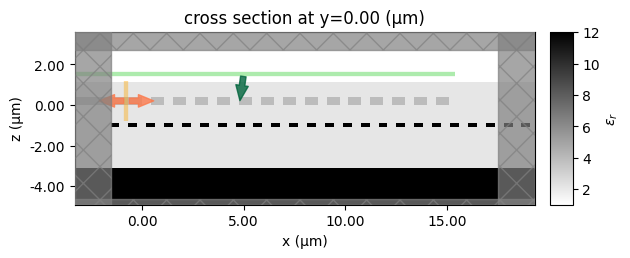

Visualize and verify the simulation setup.

sim = make_2D_full_grating_sim(2)

sim.plot_eps(y=0)

plt.show()

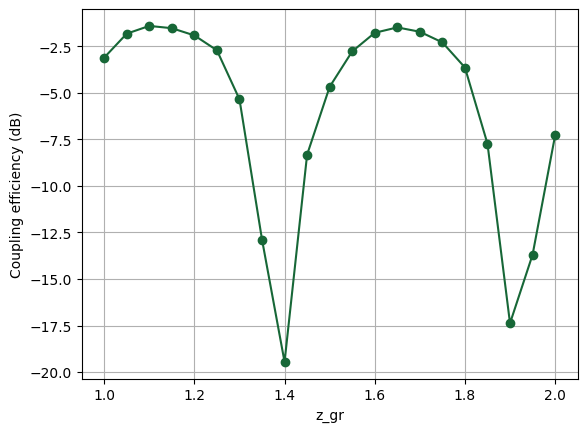

Now we perform parameter sweep of the interlayer distance to maximize the coupling efficiency.

# Design parameter and bound

params = [

tdd.ParameterFloat(name="z_gr", span=(1, 2), num_points=21),

]

# Perform parameter sweep

design_space = tdd.DesignSpace(method=method, parameters=params, path_dir="./data")

results = design_space.run(make_2D_full_grating_sim, coupling_efficiency)

# Plot the coupling efficiency as a function of z_gr

df = results.to_dataframe()

plt.plot(df["z_gr"], df["coupling efficiency"], marker="o")

plt.xlabel("z_gr")

plt.ylabel("Coupling efficiency (dB)")

plt.grid(True)

plt.show()

# Extract the best z_gr

best_row = df.loc[df["coupling efficiency"].idxmax()]

best_z_gr = best_row["z_gr"]

df.sort_values(by="coupling efficiency", ascending=False)

11:48:01 Eastern Standard Time Running 21 Simulations

| z_gr | coupling efficiency | |

|---|---|---|

| 2 | 1.10 | -1.404425 |

| 13 | 1.65 | -1.484064 |

| 3 | 1.15 | -1.526486 |

| 14 | 1.70 | -1.717543 |

| 12 | 1.60 | -1.774490 |

| 1 | 1.05 | -1.820092 |

| 4 | 1.20 | -1.914278 |

| 15 | 1.75 | -2.289349 |

| 5 | 1.25 | -2.713833 |

| 11 | 1.55 | -2.773200 |

| 0 | 1.00 | -3.106520 |

| 16 | 1.80 | -3.638100 |

| 10 | 1.50 | -4.675568 |

| 6 | 1.30 | -5.345168 |

| 20 | 2.00 | -7.289271 |

| 17 | 1.85 | -7.731516 |

| 9 | 1.45 | -8.319647 |

| 7 | 1.35 | -12.881006 |

| 19 | 1.95 | -13.697595 |

| 18 | 1.90 | -17.376482 |

| 8 | 1.40 | -19.452692 |

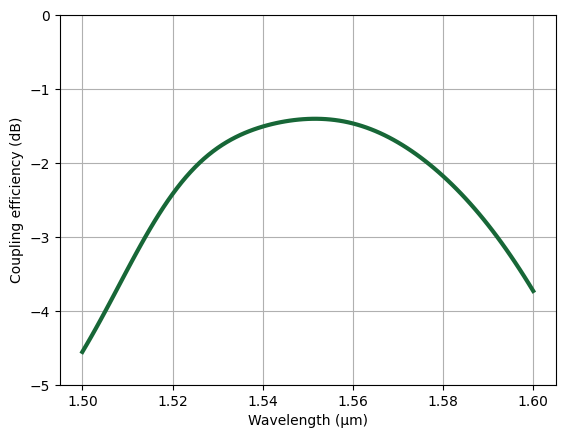

Plot the coupling efficiency spectrum for the current best design. A peak coupling efficiency of ~1.5dB is achieved.

sim = make_2D_full_grating_sim(best_z_gr)

sim_data = web.run(sim, "Optimized 2D uniform grating")

ce = 20 * np.log10(np.abs(sim_data["mode"].amps.sel(mode_index=0, direction="-").values))

plt.plot(ldas, ce, linewidth=3)

plt.ylim(-5, 0)

plt.grid()

plt.xlabel("Wavelength (µm)")

plt.ylabel("Coupling efficiency (dB)")

plt.show()

11:48:40 Eastern Standard Time Created task 'Optimized 2D uniform grating' with task_id 'fdve-b4d02f11-92cc-4220-aebb-1065f12e8c3c' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId =fdve-b4d02f11-92cc-4220-aebb-1065f12e8c3c'.

Task folder: 'default'.

Output()

11:48:41 Eastern Standard Time Maximum FlexCredit cost: 0.025. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

11:48:42 Eastern Standard Time status = success

Output()

11:48:43 Eastern Standard Time loading simulation from simulation_data.hdf5

Inverse Design Optimization of the SiN Grating¶

Finally, we perform gradient-based optimization (inverse design) to fine tune the grating. This allows each tooth width and spacing to vary independently, matching the mode profile of the fiber for maximum coupling efficiency.

def make_2D_apodized_grating_sim(design_params: np.ndarray) -> td.Simulation:

"""

Creates a 2D Tidy3D simulation for an aperiodic grating coupler.

Parameters

----------

design_params : list[float]

A list of widths defining the grating structure.

Even indices (0, 2, ...) correspond to etched widths.

Odd indices (1, 3, ...) correspond to SiN tooth widths.

Returns

-------

td.Simulation

Tidy3D simulation object.

"""

widths_SiN = design_params[1::2] # SiN tooth widths

widths_void = design_params[::2] # Etched widths

# Create SiN grating geometries from the given widths

gratings = 0

center = 0

for width_SiN, width_void in zip(widths_SiN, widths_void):

center += width_void + width_SiN / 2 # Update center position

size = width_SiN

gratings += td.Box(center=(center, 0, t_SiN / 2), size=(size, td.inf, t_SiN))

center += width_SiN / 2 # Update center position

gratings_SiN = td.Structure(geometry=gratings, medium=SiN)

# Create Si grating reflector structure

gratings_Si = make_2D_Si_grating(best_w_gr, best_p_gr, z_gr=best_z_gr)

# Create Si substrate structure

substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-inf_eff, -inf_eff, -inf_eff),

rmax=(inf_eff, inf_eff, -best_z_gr - t_box),

),

medium=Si,

)

l = 16 # Fix simulation domain size in the x direction

# Define simulation domain box

sim_box = td.Box.from_bounds(

rmin=(-lda0, 0, -best_z_gr - t_box - lda0),

rmax=(l + lda0, 0, t_SiN + t_clad + lda0),

)

# Create a Tidy3D simulation

sim = td.Simulation(

center=sim_box.center,

size=sim_box.size,

grid_spec=grid_spec,

run_time=run_time,

structures=[oxide_layer, gratings_SiN, gratings_Si, waveguide, substrate],

sources=[gaussian_beam],

monitors=[mode_monitor],

boundary_spec=boundary_spec,

)

return sim

design_params0 = np.array([best_w_gc, best_p_gc - best_w_gc] * n_gc)

sim = make_2D_apodized_grating_sim(design_params0)

sim.plot_eps(y=0)

plt.show()

Define the objective function, which is the coupling efficiency at 1550 nm.

def J(design_params: np.ndarray) -> np.ndarray:

"""

Compute the coupling efficiency (CE) for a given set of design parameters.

Parameters

----------

design_params: np.ndarray

A 1D numpy array containing the design parameters for the grating.

Returns

-------

The coupling efficiency

"""

sim = make_2D_apodized_grating_sim(design_params)

sim_data = web.run(sim, task_name="GC_invdes", verbose=False)

# Extract the complex amplitude of the desired mode at frequency freq0.

amp = sim_data["mode"].amps.sel(mode_index=0, f=freq0, direction="-").values

# Coupling efficiency is the squared magnitude of the amplitude.

ce = np.abs(amp) ** 2

return ce

Before actually running the inverse design loop, we first test the gradient calculation to ensure it works well.

dJ = ag.value_and_grad(J)

val, grad = dJ(design_params0)

print(val)

print(grad)

0.7236100065129941 [ 0.22307575 0.56603593 0.51706766 0.41977405 0.3905873 -0.03293696 -0.27843539 -0.47574742 -0.70943264 -0.75728147 -0.41855601 -0.49909601 -0.2300799 -0.29551694 -0.27728662 -0.32593653 -0.24543892 -0.26322852 -0.14479698 -0.15561174 -0.11804074 -0.13953611 -0.09500033 -0.10664506 -0.05071084 -0.06030557 -0.01361688 -0.01446665]

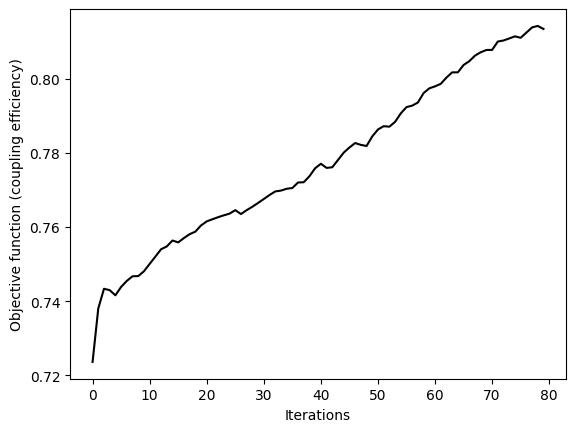

Now we iteratively improve the design. Here we use the Adam optimizer from optax.

# Hyperparameters

num_steps = 80

learning_rate = 0.005

min_feature = 0.1

# Initialize the adam optimizer with starting parameters

params = design_params0

optimizer = optax.adam(learning_rate=learning_rate)

opt_state = optimizer.init(params)

# Store history

J_history = []

params_history = []

for i in range(num_steps):

# Compute gradient and current objective function value

value, gradient = dJ(params)

# Outputs

print(f"step = {i + 1}")

print(f"\tJ = {value:.3e}")

# Compute and apply updates to the optimizer based on gradient

updates, opt_state = optimizer.update(-gradient, opt_state, params)

params[:] = optax.apply_updates(params, updates)

params = np.clip(params, a_min=min_feature, a_max=None)

# Save history

J_history.append(value)

params_history.append(params.copy())

step = 1 J = 7.236e-01 step = 2 J = 7.380e-01 step = 3 J = 7.433e-01 step = 4 J = 7.430e-01 step = 5 J = 7.416e-01 step = 6 J = 7.438e-01 step = 7 J = 7.455e-01 step = 8 J = 7.467e-01 step = 9 J = 7.468e-01 step = 10 J = 7.481e-01 step = 11 J = 7.501e-01 step = 12 J = 7.520e-01 step = 13 J = 7.540e-01 step = 14 J = 7.548e-01 step = 15 J = 7.564e-01 step = 16 J = 7.559e-01 step = 17 J = 7.570e-01 step = 18 J = 7.581e-01 step = 19 J = 7.588e-01 step = 20 J = 7.604e-01 step = 21 J = 7.615e-01 step = 22 J = 7.621e-01 step = 23 J = 7.627e-01 step = 24 J = 7.632e-01 step = 25 J = 7.636e-01 step = 26 J = 7.646e-01 step = 27 J = 7.635e-01 step = 28 J = 7.646e-01 step = 29 J = 7.655e-01 step = 30 J = 7.665e-01 step = 31 J = 7.676e-01 step = 32 J = 7.686e-01 step = 33 J = 7.696e-01 step = 34 J = 7.698e-01 step = 35 J = 7.703e-01 step = 36 J = 7.705e-01 step = 37 J = 7.720e-01 step = 38 J = 7.721e-01 step = 39 J = 7.737e-01 step = 40 J = 7.759e-01 step = 41 J = 7.771e-01 step = 42 J = 7.759e-01 step = 43 J = 7.761e-01 step = 44 J = 7.781e-01 step = 45 J = 7.801e-01 step = 46 J = 7.814e-01 step = 47 J = 7.827e-01 step = 48 J = 7.822e-01 step = 49 J = 7.819e-01 step = 50 J = 7.844e-01 step = 51 J = 7.863e-01 step = 52 J = 7.872e-01 step = 53 J = 7.871e-01 step = 54 J = 7.884e-01 step = 55 J = 7.907e-01 step = 56 J = 7.923e-01 step = 57 J = 7.927e-01 step = 58 J = 7.936e-01 step = 59 J = 7.961e-01 step = 60 J = 7.974e-01 step = 61 J = 7.979e-01 step = 62 J = 7.986e-01 step = 63 J = 8.003e-01 step = 64 J = 8.017e-01 step = 65 J = 8.017e-01 step = 66 J = 8.037e-01 step = 67 J = 8.047e-01 step = 68 J = 8.062e-01 step = 69 J = 8.071e-01 step = 70 J = 8.078e-01 step = 71 J = 8.078e-01 step = 72 J = 8.100e-01 step = 73 J = 8.103e-01 step = 74 J = 8.109e-01 step = 75 J = 8.114e-01 step = 76 J = 8.110e-01 step = 77 J = 8.124e-01 step = 78 J = 8.138e-01 step = 79 J = 8.142e-01 step = 80 J = 8.134e-01

After the optimization, we can plot the objective function history to visualize the progress.

plt.plot(J_history, c="black")

plt.xlabel("Iterations")

plt.ylabel("Objective function (coupling efficiency)")

plt.show()

Plot the final design.

opt_params = params_history[-1]

sim_final = make_2D_apodized_grating_sim(opt_params)

sim_final.plot_eps(y=0)

plt.show()

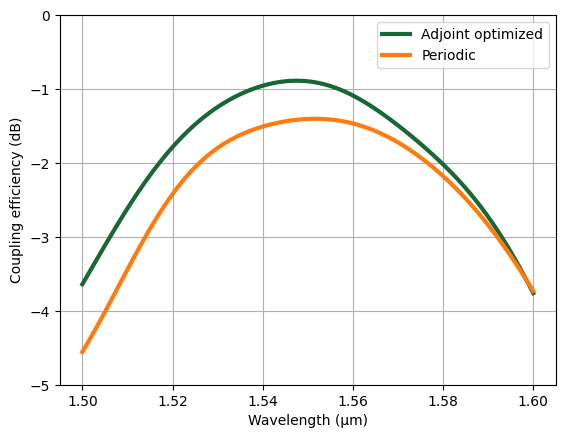

Plot the coupling efficiency spectrum of the inverse designed grating coupler against that of the periodic one. A significant improvement can be observed. The coupling efficiency is improved from ~1.5dB to sub dB level.

sim_data_final = web.run(sim_final, "Final design")

ce_final = 20 * np.log10(

np.abs(sim_data_final["mode"].amps.sel(mode_index=0, direction="-").values)

)

plt.plot(ldas, ce_final, linewidth=3, label="Adjoint optimized")

plt.plot(ldas, ce, linewidth=3, label="Periodic")

plt.ylim(-5, 0)

plt.grid()

plt.xlabel("Wavelength (µm)")

plt.ylabel("Coupling efficiency (dB)")

plt.legend()

plt.show()

12:43:24 Eastern Standard Time Created task 'Final design' with task_id 'fdve-4d43c8c5-bd1c-4e13-a6f5-cb793a9a082f' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId =fdve-4d43c8c5-bd1c-4e13-a6f5-cb793a9a082f'.

Task folder: 'default'.

Output()

12:43:25 Eastern Standard Time Maximum FlexCredit cost: 0.025. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

12:43:26 Eastern Standard Time status = success

Output()

12:43:27 Eastern Standard Time loading simulation from simulation_data.hdf5

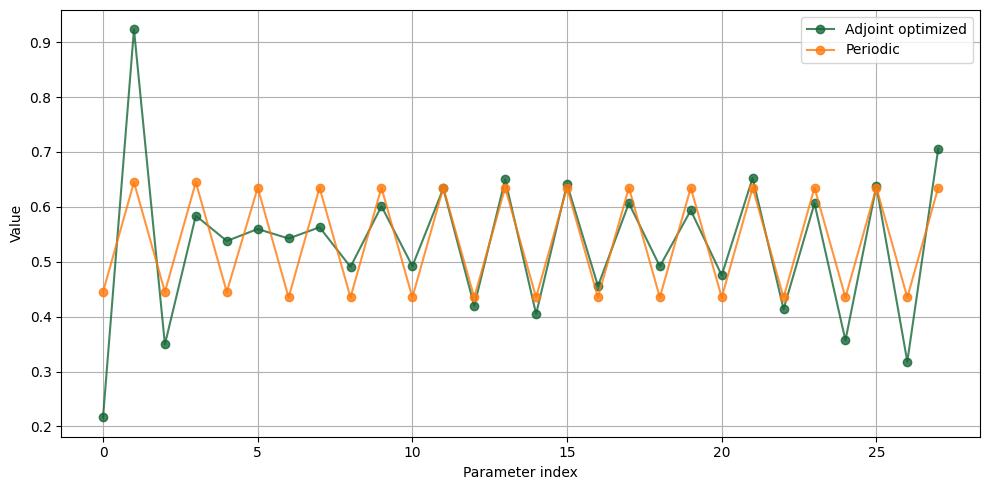

Finally, we can visually inspect the change of the design parameters. Interestingly, we can see that the most significant change occurs in the first few grating periods. The middle parts of the grating is largely unchanged.

plt.figure(figsize=(10, 5))

plt.plot(opt_params, "o-", label="Adjoint optimized", alpha=0.8)

plt.plot(design_params0, "o-", label="Periodic", alpha=0.8)

plt.xlabel("Parameter index")

plt.ylabel("Value")

plt.legend()

plt.grid(True)

plt.tight_layout()

plt.show()

Final Notes¶

In this notebook we perform all simulations in 2D, which is a cost effective and reasonably accurate way of modeling and optimizing the grating coupler. In the next step, we need to create the full grating in 3D (either a linear or focusing configuration) to verify and possibly further optimize the performance.