The demand for ever higher input/output (I/O) bandwidths has driven the development of co-packaged optics (CPO), where optical components are integrated alongside the application-specific integrated circuit (ASIC). This approach enables higher transmission rates and lower energy consumption, helping to circumvent the packaging bottlenecks that limit next-generation communication devices.

A natural evolution is to bring the optics directly onto the silicon interposer, reducing the electrical distance between transmitter/receiver and ASIC. This tighter integration is particularly relevant for datacenters, high-performance computing (HPC) clusters, and AI systems, where switch bandwidth and energy efficiency are critical.

At the same time, chip power continues to rise, requiring increasingly complex cooling solutions. Thermal management becomes a central challenge, since temperature variations directly impact the performance of microring modulators and filters used in dense wavelength-division multiplexing (DWDM) links.

In this notebook, we illustrate how to set up a simplified 3D thermal simulation of a microring integrated on a silicon interposer, inspired by the paper of Benjamin G. Lee, Nikola Nedovic, Thomas H. Greer, and C. Thomas Gray, "Beyond CPO: A Motivation and Approach for Bringing Optics Onto the Silicon Interposer", Journal of Lightwave Technology 41(4), 1152–1165 (2023). DOI: https://doi.org/10.1109/JLT.2022.3219379.

The key steps are:

-

Define the material stack — silicon interposer, buried oxide, photonic layer, BEOL glass, copper heat spreader, and heaters.

-

Assign thermal properties — capacity, conductivity, and density for each material.

-

Set up boundary conditions — insulating boundaries, with thermal impedance applied at the top of the heat spreader.

-

Apply power perturbations — ASIC load steps and local heater power steps.

-

Run transient simulations — compute the time-dependent temperature distribution across the device.

-

Analyze results — observe the thermal response of the microring, neighbor coupling, and evaluate stabilization requirements for control loops.

import matplotlib.pyplot as plt

import numpy as np

import tidy3d as td

import tidy3d.web as web

# Suppress warnings due to structure reaching boundaries, which can be disregarded for Heat simulations

td.config.logging_level = "ERROR"

Simulation Setup¶

First we will define an auxiliary function to easily stack the different parts of the geometry.

def stack_box(

structure_1,

structure_2,

plane="x",

horizontal="right",

vertical="top",

gap_h=0,

gap_v=0,

new_name=None,

):

"""

Aligns and stacks *structure_2* relative to *structure_1* in a given plane

with configurable horizontal and vertical positioning.

Parameters

----------

structure_1 : tidy3d.Structure

Tidy3D structure used as the base.

structure_2 : tidy3d.Structure

Tidy3D structure to be translated and stacked relative to *structure_1*.

plane : str, optional

Plane of alignment ('x', 'y', or 'z'). Default is 'x'.

horizontal : str, optional

Horizontal alignment relative to *structure_1* ('left', 'right', 'center').

Default is 'right'.

vertical : str, optional

Vertical alignment relative to *structure_1* ('top', 'bottom', 'center').

Default is 'top'.

gap_h : float, optional

Horizontal gap between structures. Default is 0.

gap_v : float, optional

Vertical gap between structures. Default is 0.

new_name : str, optional

Name for the updated *structure_2*. If None, retains original name.

Returns

-------

tidy3d.Structure

A copy of *structure_2* translated to the new aligned position.

"""

box_1 = structure_1.geometry.bounding_box

box_2 = structure_2.geometry.bounding_box

c1 = np.array(box_1.center)

c2 = np.array(box_2.center)

s1 = np.array(box_1.size)

s2 = np.array(box_2.size)

# Default: new center is box_1 center

new_center = c1.copy()

# Which plane are we stacking in?

axis = {"x": 0, "y": 1, "z": 2}[plane]

aux = [0, 1, 2]

aux.remove(axis)

horizontal_axes = min(aux)

vertical_axes = max(aux)

for i in [(horizontal, horizontal_axes, gap_h), (vertical, vertical_axes, gap_v)]:

if i[0] == "center":

new_center[i[1]] = c1[i[1]]

elif i[0] == "left":

new_center[i[1]] = c1[i[1]] - s1[i[1]] / 2 + (s2[i[1]] / 2) + i[2]

elif i[0] == "right":

new_center[i[1]] = c1[i[1]] + s1[i[1]] / 2 - (s2[i[1]] / 2) + i[2]

elif i[0] == "top":

new_center[i[1]] = c1[i[1]] + s1[i[1]] / 2 + (s2[i[1]] / 2) + i[2]

elif i[0] == "bottom":

new_center[i[1]] = c1[i[1]] - s1[i[1]] / 2 - (s2[i[1]] / 2) - i[2]

translated_geometry = structure_2.geometry.translated(

x=-c2[0] + new_center[0], y=-c2[1] + new_center[1], z=-c2[2] + new_center[2]

)

return structure_2.updated_copy(

geometry=translated_geometry, name=new_name if new_name else structure_2.name

)

Material properties¶

For heating simulations, we need to add a heat specification to the Tidy3D MultiPhysicsMedium object via the heat_spec argument, defining the thermal material properties:

- Specific heat capacity in J/(kg·K)

- Thermal conductivity in W/(µm·K)

- Density in kg/µm³, required for transient heat analysis

Si_n = 3.4777 # Si refractive index

Si_n_slope = 1.86e-4 # Si thermo-optic coefficient dn/dT [1/K]

Si_capacity = 710 # Si specific heat capacity [J/(kg·K)]

Si_conductivity = 148e-6 # Si thermal conductivity [W/(µm·K)]

Si_density = 2.33e-15 # Si density [kg/µm^3] (2330 kg/m^3)

freq0 = td.C_0 / 1.5

Si_optical = td.Medium.from_nk(n=Si_n, k=0, freq=freq0)

Si_heat = td.SolidSpec(capacity=Si_capacity, conductivity=Si_conductivity, density=Si_density)

Si = td.MultiPhysicsMedium(optical=Si_optical, heat=Si_heat, name="Si")

SiO2_n = 1.444 # SiO2 refractive index

SiO2_n_slope = 1e-5 # SiO2 thermo-optic coefficient dn/dT [1/K]

SiO2_capacity = 703 # SiO2 specific heat capacity [J/(kg·K)]

SiO2_conductivity = 1.38e-6 # SiO2 thermal conductivity [W/(µm·K)]

SiO2_density = 2.634e-15 # SiO2 density [kg/µm^3] (2634 kg/m^3)

# Alternative way of defining a medium specification

SiO2_optical = td.Medium(permittivity=SiO2_n**2)

SiO2_heat = td.SolidSpec(

capacity=SiO2_capacity, conductivity=SiO2_conductivity, density=SiO2_density

)

SiO2 = td.MultiPhysicsMedium(optical=SiO2_optical, heat=SiO2_heat, name="SiO2")

Cu_capacity = 385 # Cu specific heat capacity [J/(kg·K)]

Cu_conductivity = 401e-6 # Cu thermal conductivity [W/(µm·K)]

Cu_density = 8.96e-15 # Cu density [kg/µm^3] (8960 kg/m^3)

Cu_optical = td.PECMedium()

Cu_heat = td.SolidSpec(capacity=Cu_capacity, conductivity=Cu_conductivity, density=Cu_density)

Cu = td.MultiPhysicsMedium(

optical=Cu_optical,

heat=Cu_heat,

name="Cu",

)

# BEOL layer (modeled as porous SiO2 / low-k dielectric)

BEOL_capacity = 703 # J/(kg·K), similar to SiO2

BEOL_conductivity = 0.45e-6 # W/(µm·K), reduced effective conductivity

BEOL_density = 2.2e-15 # kg/µm^3, lower density due to porosity

beol_SiO2_optical = td.Medium(permittivity=SiO2_n**2)

beol_SiO2_heat = td.SolidSpec(

capacity=BEOL_capacity,

conductivity=BEOL_conductivity,

density=BEOL_density,

)

beol_SiO2 = td.MultiPhysicsMedium(

optical=beol_SiO2_optical,

heat=beol_SiO2_heat,

name="BEOL",

)

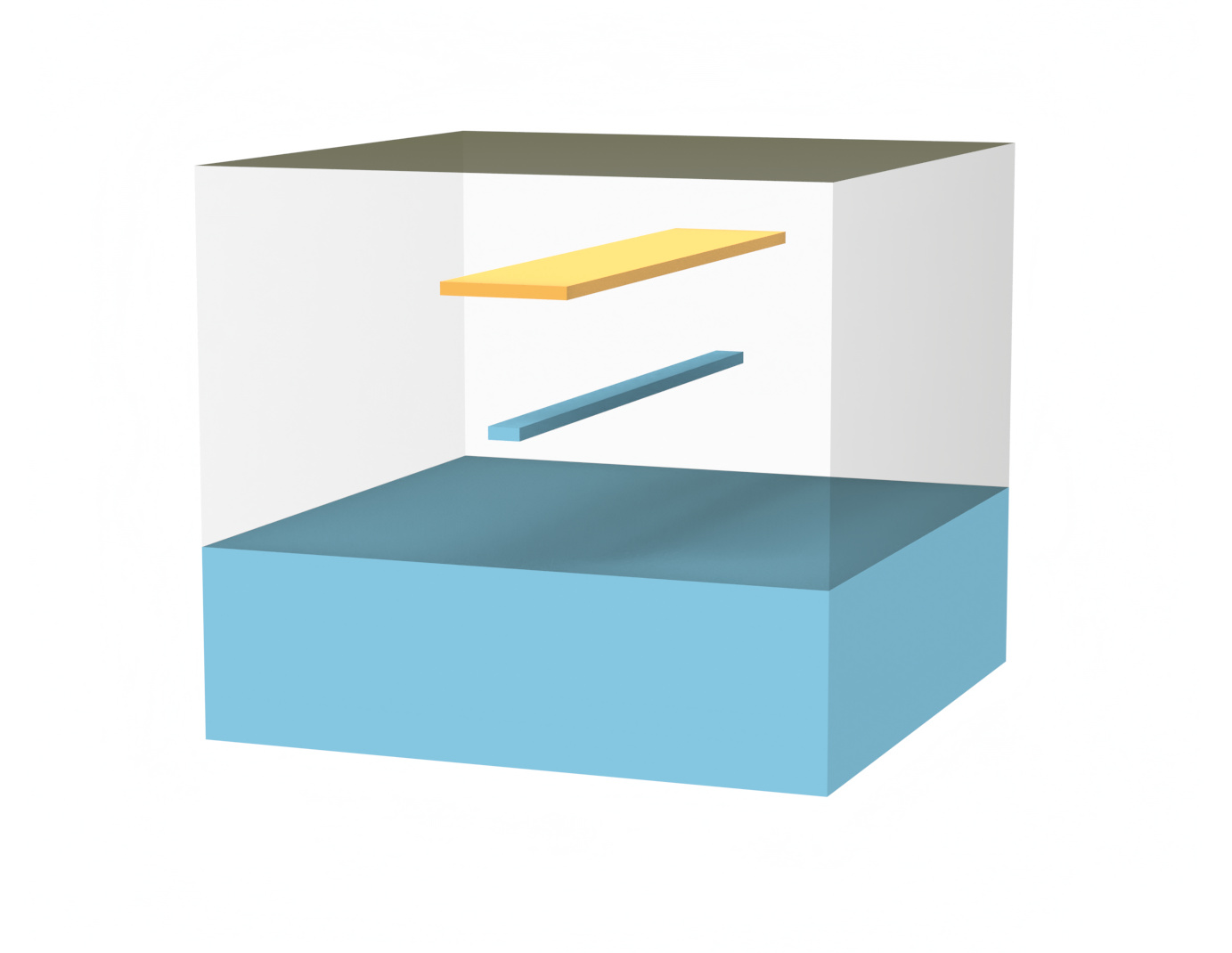

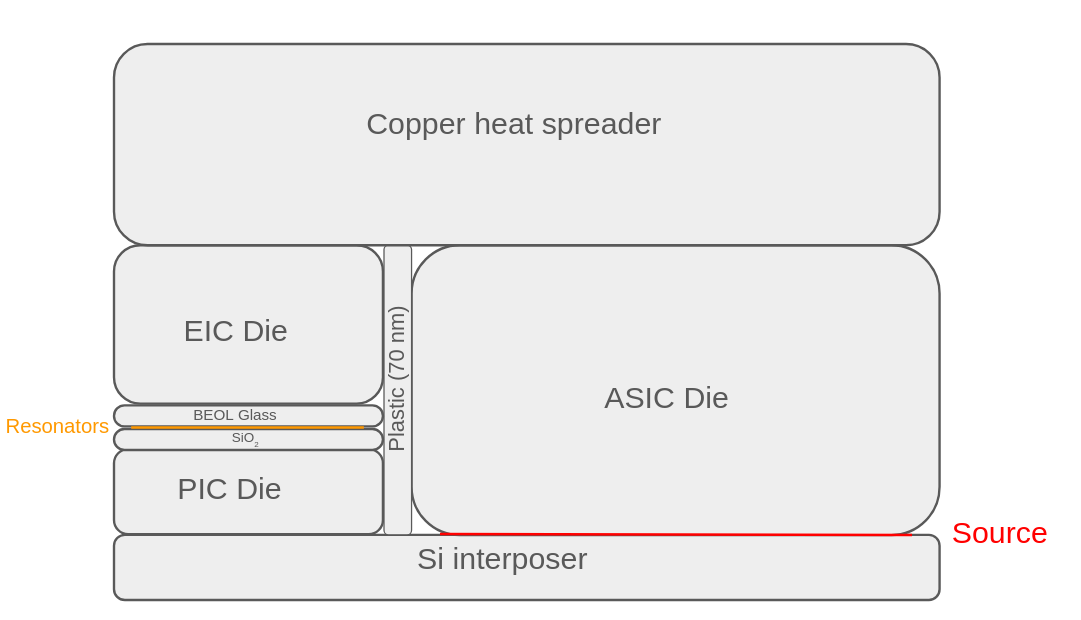

Simulation Geometry¶

Next, we will define the different layers of the structure.

The stack consists of:

- Copper heat spreader on top, which serves as the main cooling interface.

- ASIC (logic die), the primary heat source in the system.

- Plastic molding compound as a thin spacer between the ASIC and the photonic layers.

- Photonic Integrated Circuit (PIC) on the interposer surface, containing the microring resonators.

- Buried oxide (BOX) below the silicon waveguides, providing thermal and optical isolation.

- BEOL glass above the rings, insulating them from the electronic circuits.

- Metal heaters embedded in glass just above the rings for thermo-optic tuning.

- Silicon interposer at the bottom.

A schematic can be seen in the image below:

# Unit helpers (all geometry in µm)

mm = 1e3

width = 160 * mm

# Silicon interposer (bottom substrate, 100 µm thick in the paper)

interposer_thickness = 0.1 * mm

interposer_length = 10 * mm

Silicon_interposer = td.Structure(

geometry=td.Box(

center=(0, 0, -interposer_thickness / 2),

size=(interposer_length, width, interposer_thickness),

),

name="Silicon_interposer",

medium=Si,

)

# ASIC die (logic die, ~1 mm thick)

asic_thickness = 1 * mm

asic_length = 5 * mm

ASIC_Die = td.Structure(

geometry=td.Box(size=(asic_length, width, asic_thickness)),

name="ASIC_Die",

medium=Si,

)

# Plastic molding compound spacer between ASIC and PIC/EIC (~70 nm)

silicon_gap_thickness = 0.07 # 70 nm

silicon_gap_length = 10 * mm

Silicon_gap = td.Structure(

geometry=td.Box(size=(silicon_gap_length, width, silicon_gap_thickness)),

name="Molding_spacer",

medium=SiO2, # simple proxy; replace with a polymer if desired

)

# Optional placeholder “source region” (e.g., for heater or power injection)

Source = td.Structure(

geometry=td.Box(size=(5 * mm, width, 0.01)), # 10 nm

name="Source",

medium=Si, # set to appropriate medium if used

)

# PIC die on interposer (photonic Si layer stack)

buried_sio2_thickness = 2 # µm (BOX)

beol_thickness = 10 # µm (BEOL glass)

# Photonic Si core (100 µm total PIC die; subtract BOX and BEOL to keep total)

pic_thickness = 0.1 * mm

pic_length = 5 * mm

PIC_Die = td.Structure(

geometry=td.Box(

size=(pic_length, width, pic_thickness - buried_sio2_thickness - beol_thickness)

),

name="PIC_Die",

medium=Si,

)

# Buried oxide (BOX) under the photonic Si

buried_sio2 = td.Structure(

geometry=td.Box(size=(pic_length, width, buried_sio2_thickness)),

name="buried_sio2",

medium=SiO2,

)

# BEOL dielectric above the photonic Si (glass/low-k stack)

beol = td.Structure(

geometry=td.Box(size=(pic_length, width, beol_thickness)),

name="beol",

medium=beol_SiO2,

)

# EIC die above the PIC (fills remaining thickness up to ~1 mm total)

eic_thickness = 1 * mm - pic_thickness

eic_length = pic_length

EIC_Die = td.Structure(

geometry=td.Box(size=(eic_length, width, eic_thickness)),

name="EIC_Die",

medium=Si,

)

# Copper heat spreader on top (~0.5 mm)

heat_spreader_thickness = 0.5 * mm

heat_spreader_length = 10 * mm

Heat_spreader = td.Structure(

geometry=td.Box(size=(heat_spreader_length, width, heat_spreader_thickness)),

name="Heat_spreader",

medium=Cu,

)

# Lateral gap placeholder

die_gap_thickness = asic_thickness

die_gap_length = 0.07 # 70 nm in x

Die_gap = td.Structure(

geometry=td.Box(size=(die_gap_length, width, die_gap_thickness)),

name="Die_gap_lateral",

medium=SiO2,

)

# Stack the structures (using your helper `stack_box`)

ASIC_Die = stack_box(Silicon_interposer, ASIC_Die, plane="y", horizontal="right", vertical="top")

PIC_Die = stack_box(Silicon_interposer, PIC_Die, plane="y", horizontal="left", vertical="top")

buried_sio2 = stack_box(PIC_Die, buried_sio2, plane="y", horizontal="left", vertical="top")

beol = stack_box(buried_sio2, beol, plane="y", horizontal="left", vertical="top")

EIC_Die = stack_box(beol, EIC_Die, plane="y", horizontal="center", vertical="top")

Die_gap = stack_box(ASIC_Die, Die_gap, plane="y", horizontal="left", vertical="center")

Heat_spreader = stack_box(EIC_Die, Heat_spreader, plane="y", horizontal="left", vertical="top")

scene = td.Scene(

structures=[

Silicon_interposer,

# Silicon_gap,

ASIC_Die,

PIC_Die,

EIC_Die,

Die_gap,

Heat_spreader,

beol,

buried_sio2,

]

)

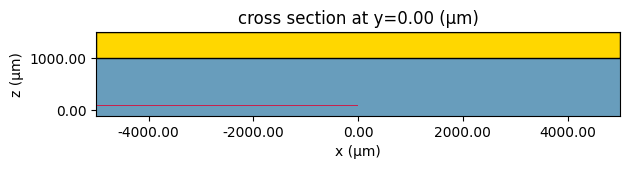

ax = scene.plot(y=0)

plt.show()

Defining Mesh¶

We will use a UniformUnstructuredGrid object to create a uniform unstructured mesh. The relative_min_dl is set to a low value due to the small features in the geometry.

mesh = td.UniformUnstructuredGrid(dl=0.005 * mm, relative_min_dl=0.0003)

Defining Source¶

Here, we will use a linear source at the bottom of the ASIC die. The HeatSource object is assigned to the ASIC die structure, with a custom power distribution only at its bottom.

# Line heat source

x = np.linspace(0 * mm, 5 * mm, 100)

y = [0]

z = [0]

rate = 2 * (500 / 800) * 1e-9 # W/um^3

data = rate * np.ones((len(x), 1, 1))

coords = dict(x=x, y=y, z=z)

custom_rate = td.SpatialDataArray(data, coords=coords)

heat_source = td.HeatSource(structures=["ASIC_Die"], rate=custom_rate) # W/um^3

Defining Monitors¶

We will add a TemperatureMonitor to track the temperature distribution across the simulation domain.

temp_mnt = td.TemperatureMonitor(

size=(td.inf, 0, td.inf), name="temperature", unstructured=True, conformal=True

)

Boundary Conditions¶

The boundary conditions are all insulating, except for the z+ boundary, which uses a ConvectionBC with a heat impedance of $3\times10^7 \mu\text{m}^2\text{ K/W}$.

insulating = td.HeatBoundarySpec(

condition=td.HeatFluxBC(flux=0),

placement=td.SimulationBoundary(surfaces=["x+", "x-", "z-"]),

)

heat_impedance = 3e7 # µm^2 K/W

top_boundary = td.HeatBoundarySpec(

condition=td.ConvectionBC(

ambient_temperature=300, # K

transfer_coeff=1 / heat_impedance, # W/(K*µm^2)

),

placement=td.SimulationBoundary(surfaces=["z+"]),

)

Steady Heat Simulation¶

First, we will assemble all components and create the HeatChargeSimulation object for the steady-state simulation.

We can see warnings regarding structures extending into the PML

heat_sim = td.HeatChargeSimulation(

center=scene.center,

size=scene.size,

medium=scene.medium,

structures=scene.structures,

boundary_spec=[insulating, top_boundary],

sources=[heat_source],

grid_spec=mesh,

monitors=[temp_mnt],

)

Finally, we can use web.run to upload the simulation to the cloud, run it, monitor progress, download the data, and load it into the HeatChargeSimulationData object for post-processing.

steady_data = web.run(heat_sim, task_name="CPOHeat_Steady")

Output()

15:40:05 -03 loading simulation from simulation_data.hdf5

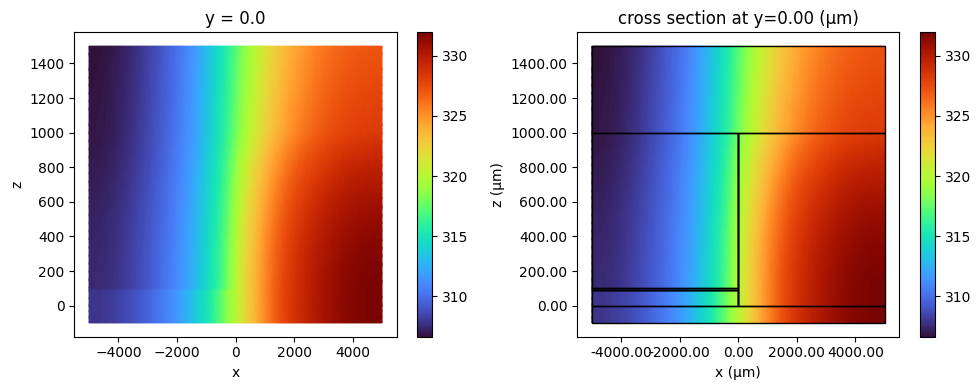

Visualizing Steady-State Results¶

We can call the .plot method to visualize the field distribution in the simulation plane.

As we can see, the thin plastic region provides good insulation for the ASIC die. For reference, the structures are highlighted in the figure on the right.

fig, (ax, ax2) = plt.subplots(1, 2, figsize=(10, 4))

steady_data["temperature"].temperature.plot(grid=False, ax=ax)

ax.set_aspect("auto")

ax.collections[-1].set_cmap("turbo")

steady_data["temperature"].temperature.plot(grid=False, ax=ax2)

scene.plot(y=0, ax=ax2, fill_structures=False)

ax2.set_aspect("auto")

ax2.collections[-1].set_cmap("turbo")

ax2.set_xlim(ax.get_xlim())

ax2.set_ylim(ax.get_ylim())

plt.tight_layout()

plt.show()

Transient Analysis¶

For transient heating analysis, the only modification is providing an UnsteadyHeatAnalysis object to the analysis_spec parameter of the HeatChargeSimulation model object, specifying the initial temperature, number of time steps, and step size.

We will reuse the previously created object and update it with the updated_copy method.

time_step_2d = 1e-3

total_time_steps_2d = 1000

time_spec = td.UnsteadyHeatAnalysis(

initial_temperature=300,

unsteady_spec=td.UnsteadySpec(

time_step=time_step_2d,

total_time_steps=total_time_steps_2d,

),

)

heat_sim_transient = heat_sim.updated_copy(analysis_spec=time_spec)

heat_data_transient = web.run(heat_sim_transient, "CPO_2D_Transient")

Output()

15:40:28 -03 loading simulation from simulation_data.hdf5

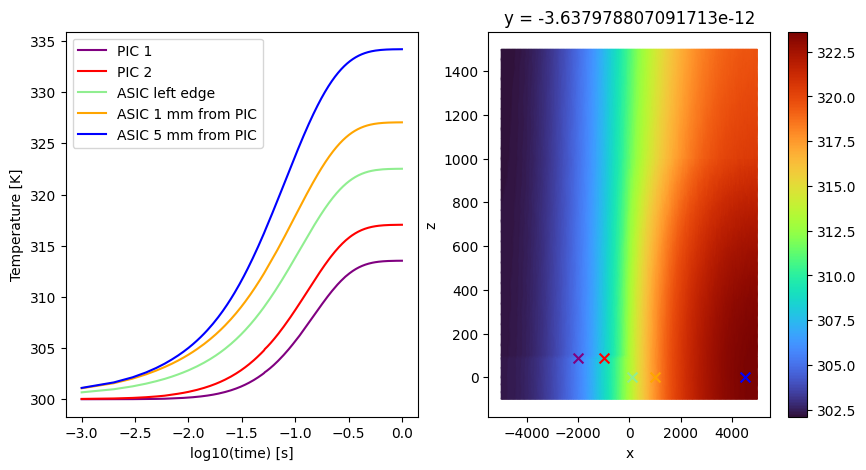

Visualizing Transient Results¶

Next we will visualize the results at typical resonator positions and at different points on the ASIC die.

fig, Ax = plt.subplots(1, 2, figsize=(10, 5))

PIC_z = buried_sio2.geometry.bounding_box.center[2]

temp1 = heat_data_transient["temperature"].temperature.sel(x=-2000, z=PIC_z, method="nearest")

temp2 = heat_data_transient["temperature"].temperature.sel(x=-1000, z=PIC_z, method="nearest")

temp3 = heat_data_transient["temperature"].temperature.sel(x=100, z=0, method="nearest")

temp4 = heat_data_transient["temperature"].temperature.sel(x=1000, z=0, method="nearest")

temp5 = heat_data_transient["temperature"].temperature.sel(x=4500, z=0, method="nearest")

time_steps = time_step_2d * np.arange(total_time_steps_2d)

Ax[0].plot(np.log10(time_steps), temp1.values.squeeze(), color="purple", label="PIC 1")

Ax[0].plot(np.log10(time_steps), temp2.values.squeeze(), color="red", label="PIC 2")

Ax[0].plot(np.log10(time_steps), temp3.values.squeeze(), color="lightgreen", label="ASIC left edge")

Ax[0].plot(np.log10(time_steps), temp4.values.squeeze(), color="orange", label="ASIC 1 mm from PIC")

Ax[0].plot(np.log10(time_steps), temp5.values.squeeze(), color="blue", label="ASIC 5 mm from PIC")

Ax[0].set_xlabel("log10(time) [s]")

Ax[0].set_ylabel("Temperature [K]")

Ax[0].legend()

_ = heat_data_transient["temperature"].temperature.sel(t=99).plot(grid=False, ax=Ax[1])

Ax[1].set_aspect("auto")

Ax[1].collections[-1].set_cmap("turbo")

Ax[1].scatter(-2000, PIC_z, color="purple", s=50, marker="x")

Ax[1].scatter(-1000, PIC_z, color="red", s=50, marker="x")

Ax[1].scatter(100, 0, color="lightgreen", s=50, marker="x")

Ax[1].scatter(1000, 0, color="orange", s=50, marker="x")

Ax[1].scatter(4500, 0, color="blue", s=50, marker="x")

plt.show()

/tmp/ipykernel_427248/680229564.py:14: RuntimeWarning: divide by zero encountered in log10 Ax[0].plot(np.log10(time_steps), temp1.values.squeeze(), color="purple", label="PIC 1") /tmp/ipykernel_427248/680229564.py:15: RuntimeWarning: divide by zero encountered in log10 Ax[0].plot(np.log10(time_steps), temp2.values.squeeze(), color="red", label="PIC 2") /tmp/ipykernel_427248/680229564.py:16: RuntimeWarning: divide by zero encountered in log10 Ax[0].plot(np.log10(time_steps), temp3.values.squeeze(), color="lightgreen", label="ASIC left edge") /tmp/ipykernel_427248/680229564.py:17: RuntimeWarning: divide by zero encountered in log10 Ax[0].plot(np.log10(time_steps), temp4.values.squeeze(), color="orange", label="ASIC 1 mm from PIC") /tmp/ipykernel_427248/680229564.py:18: RuntimeWarning: divide by zero encountered in log10 Ax[0].plot(np.log10(time_steps), temp5.values.squeeze(), color="blue", label="ASIC 5 mm from PIC")

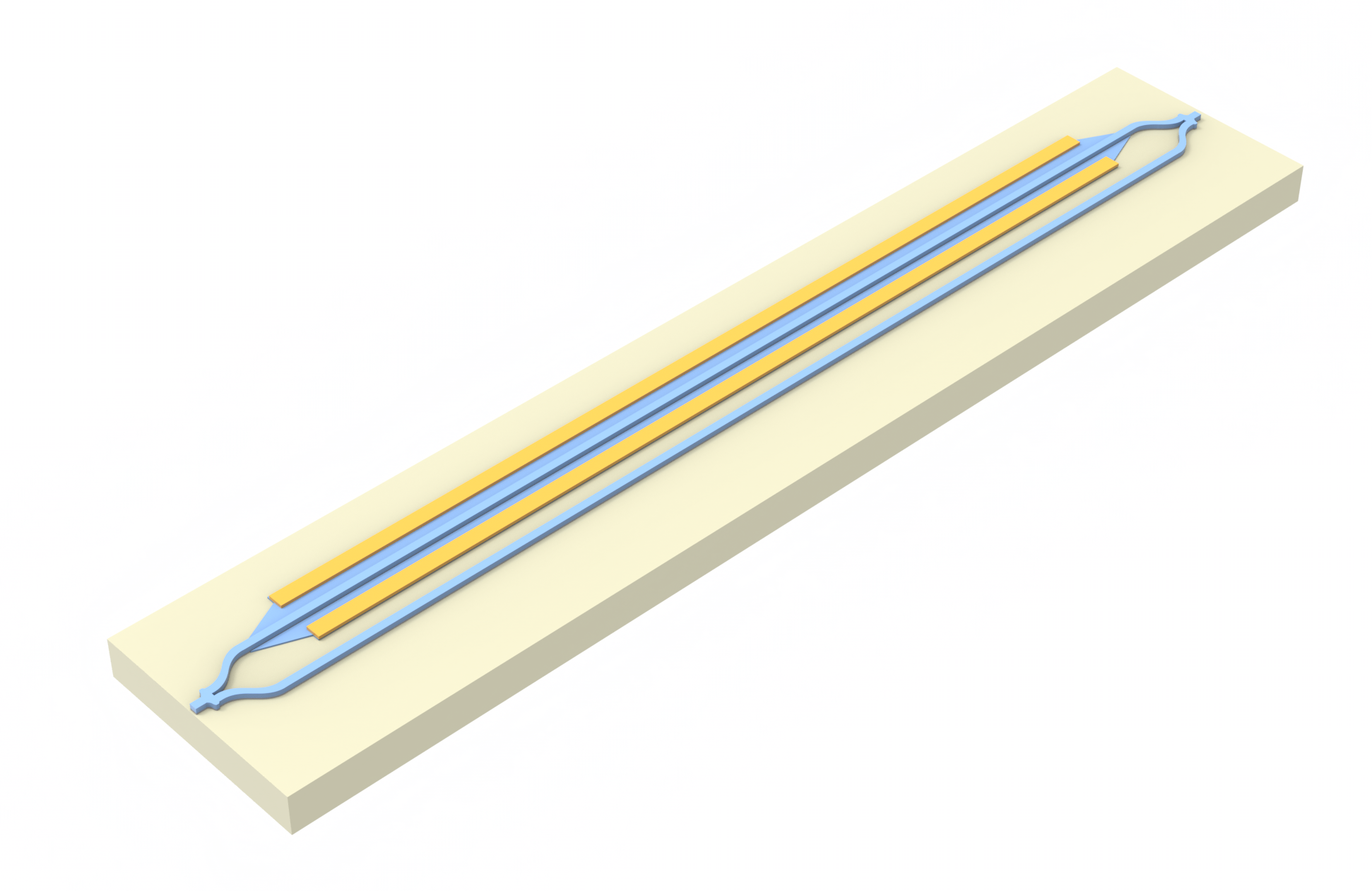

3D Transient Simulation¶

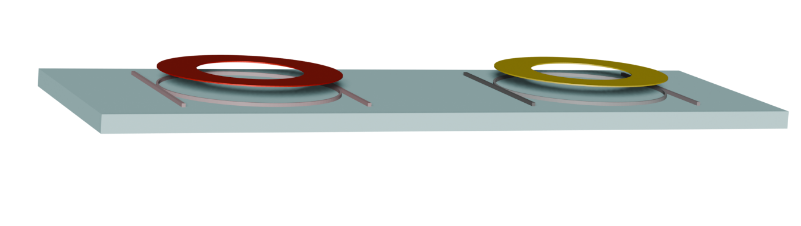

Now we will investigate the effect of the heater on neighboring resonators.

A localized power step is applied to one microring heater, and the transient temperature response is computed in 3D.

This allows us to observe the ring’s heating dynamics and quantify thermal crosstalk with adjacent resonators.

Defining the Ring and Heater Geometry¶

# Ring center (aligned above the buried oxide layer)

mrr_center = (

-2000,

0,

buried_sio2.geometry.bounding_box.center[2] + buried_sio2.geometry.bounding_box.size[2] / 2,

)

# Heater placed 1 µm above the ring center in z

heater_center = (mrr_center[0], mrr_center[1], mrr_center[2] + 1)

# Ring dimensions (radius = 20 µm, width = 1 µm)

ring_radius = 20

ring_width = 1

# Ring geometry defined as a hollow cylinder (outer – inner cylinder)

ring_geometry = td.Cylinder(

center=heater_center, radius=ring_radius, length=0.22, axis=2

) - td.Cylinder(center=heater_center, radius=ring_radius - ring_width, length=0.22, axis=2)

# Define first microring (Si core)

ring1 = td.Structure(geometry=ring_geometry, medium=Si, name="ring")

# Define heater overlapping the ring geometry (Cu)

heater1 = td.Structure(geometry=ring_geometry, medium=Cu, name="heater")

# Place heater above ring1 with a vertical gap of 1 µm

heater1 = stack_box(

ring1, heater1, plane="y", horizontal="center", vertical="top", gap_v=1, new_name="heater1"

)

# Duplicate ring1 to create a neighboring ring at 100 µm horizontal separation

ring2 = stack_box(

ring1, ring1, plane="y", horizontal="left", vertical="center", gap_h=100, new_name="ring2"

)

# Place heater above the second ring with the same 1 µm gap

heater2 = stack_box(

ring2, heater1, plane="y", horizontal="center", vertical="top", gap_v=1, new_name="heater2"

)

The new source is a uniform source located right next to the resonator's heater.

# Line heat source

x = np.linspace(0 * mm, 5 * mm, 100)

y = [0]

z = [0]

power = 5e-3 # 1 mW

volume = 0.22 * np.pi * (ring_radius**2 - (ring_radius - ring_width) ** 2) # um^3

rate = power / volume # W/um^3

heat_source3 = td.HeatSource(structures=["heater1"], rate=rate) # W/um^3

Now we can place the geometry and new source together and update the 2D simulation.

scene_3d = scene.updated_copy(structures=list(scene.structures) + [ring1, heater1, ring2, heater2])

center_3d = mrr_center

size_3d = (1 * mm,) * 3

heat_sim_3d = heat_sim.updated_copy(

center=center_3d, size=size_3d, structures=scene_3d.structures, sources=[heat_source3]

)

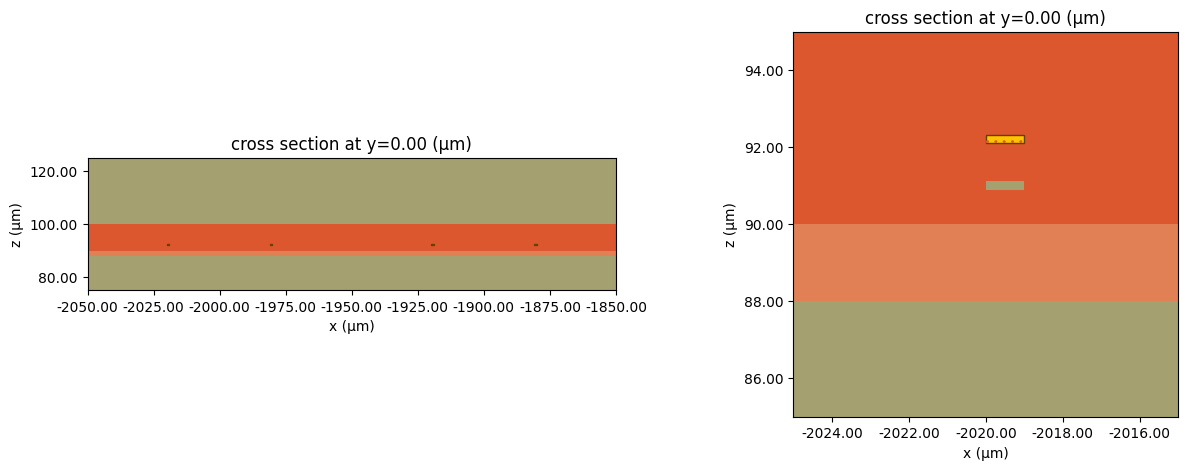

First, let's visualize the geometry:

fig, Ax = plt.subplots(1, 2, figsize=(15, 5))

ax1 = heat_sim_3d.plot(y=0, ax=Ax[0])

ax1.set_xlim(-2050, -1850)

ax1.set_ylim(75, 125)

ax2 = heat_sim_3d.plot(y=0, ax=Ax[1])

ax2.set_xlim(-2025, -2015)

ax2.set_ylim(85, 95)

# ax2.set_aspect('auto')}

plt.show()

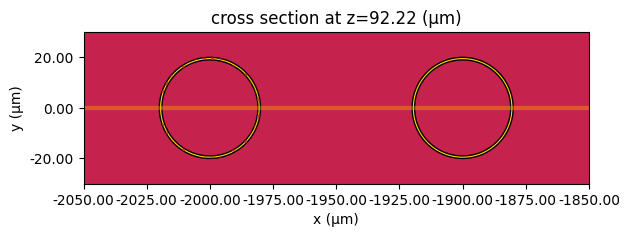

ax = heat_sim_3d.plot(z=heater2.geometry.bounding_box.center[2])

ax.set_xlim(-2050, -1850)

ax.set_ylim(-30, 30)

plt.show()

3D Transient Analysis¶

Next, we will create an UnsteadyHeatAnalysis object for the 3D analysis and run the simulation.

time_step = 1e-6

total_time_steps = 1000

time_spec = td.UnsteadyHeatAnalysis(

initial_temperature=300,

unsteady_spec=td.UnsteadySpec(

time_step=time_step,

total_time_steps=total_time_steps,

),

)

heat_sim_transient_3d = heat_sim_3d.updated_copy(analysis_spec=time_spec)

heat_data_transient_3d = web.run(heat_sim_transient_3d, "CPO_3D_Transient")

Output()

15:40:45 -03 loading simulation from simulation_data.hdf5

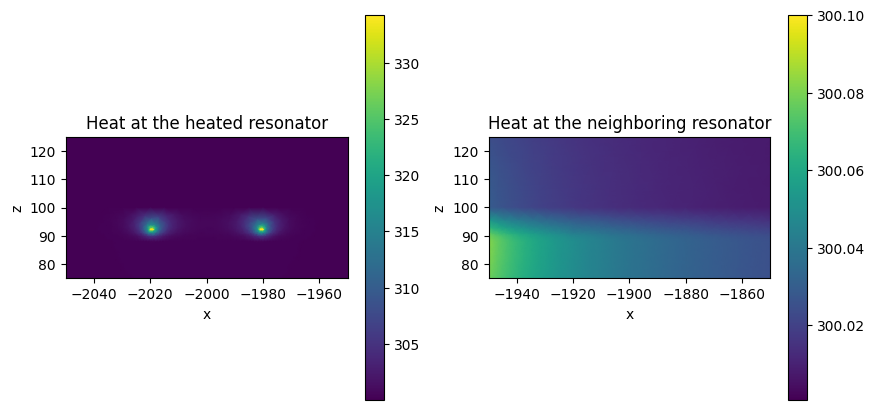

Visualizing Temperature Distribution¶

We can now visualize the heat distribution in the heated and neighboring resonators. The crosstalk is very small and can only be seen when saturating the temperature values in the figure on the right.

fig, Ax = plt.subplots(1, 2, figsize=(10, 5))

ax1 = heat_data_transient_3d["temperature"].temperature.sel(t=999).plot(grid=False, ax=Ax[0])

ax1.set_xlim(-2050, -1950)

ax1.set_ylim(75, 125)

ax1.set_title("Heat at the heated resonator")

ax2 = (

heat_data_transient_3d["temperature"]

.temperature.sel(t=999)

.plot(grid=False, ax=Ax[1], vmax=300.1)

)

ax2.set_xlim(-1950, -1850)

ax2.set_ylim(75, 125)

ax2.set_title("Heat at the neighboring resonator")

plt.show()

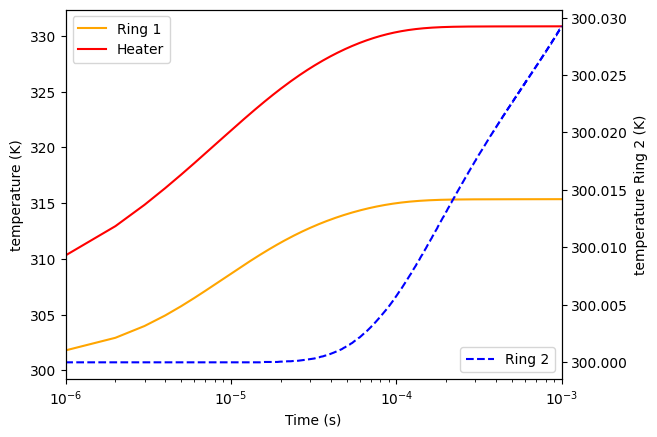

Finally, we can analyze the heat dynamics. As we can see, the heated resonator transient response follows closely the heater, while the neighboring resonator shows only a small temperature rise with a noticeable delay.

This analysis is important for understanding thermal crosstalk between adjacent devices and for defining the requirements for stabilization and control loops that keep the microrings properly tuned.

# Coordinates for sampling temperatures

x_ring_1 = ring1.geometry.bounding_box.center[0] + 19 # sample point near ring radius

y_ring_1 = ring1.geometry.bounding_box.center[1] # same y as ring center

z_ring_1 = ring1.geometry.bounding_box.center[2] # same z as ring center

# Temperature at Ring 1

temp_ring1 = heat_data_transient_3d["temperature"].temperature.sel(

x=x_ring_1,

y=y_ring_1,

z=z_ring_1,

)

# Temperature at Ring 2 (100 µm away in x)

temp_ring2 = heat_data_transient_3d["temperature"].temperature.sel(

x=x_ring_1 + 100, y=y_ring_1, z=z_ring_1, method="nearest"

)

# Temperature at Heater (1 µm above Ring 1)

temp_heater1 = heat_data_transient_3d["temperature"].temperature.sel(

x=x_ring_1, y=y_ring_1, z=z_ring_1 + 1, method="nearest"

)

# Plot transients

fig, ax = plt.subplots()

time = time_step * np.arange(total_time_steps)

# Plot Ring 1 and Heater on the primary y-axis

ax.plot(time, temp_ring1.squeeze(), "-", label="Ring 1", color="orange")

ax.plot(time, temp_heater1.squeeze(), "-", label="Heater", color="red")

ax.set_ylabel("temperature (K)")

ax.set_xlabel("Time (s)")

ax.set_xscale("log")

ax.set_xlim(1e-6, 1e-3)

ax.legend(loc=2)

# Plot Ring 2 on a secondary y-axis for clarity

ax2 = ax.twinx()

ax2.plot(time, temp_ring2.squeeze(), "--", label="Ring 2", color="blue")

ax2.set_ylabel("temperature Ring 2 (K)")

ax2.legend(loc=4)

plt.show()