When working with low-index-contrast waveguides, such as SiN embedded in SiO₂, the optical field can become highly delocalized, especially in narrow structures such as the tip of an edge coupler, resulting in a large mode field size. In such cases, it's important to carefully define the mode plane to prevent extended evanescent fields from reaching the Perfectly Matched Layer (PML), as this can lead to unphysical losses and inaccurate simulation results.

In this notebook, we will demonstrate how an insufficiently large plane size can result in unphysical losses.

We will also demonstrate how to assemble a ModeSolver simulation to quickly determine whether the simulation plane is large enough. Furthermore, we will illustrate how to create a grid to efficiently run a simulation with a sufficiently large plane size.

import matplotlib.pyplot as plt

import numpy as np

import tidy3d as td

import tidy3d.web as web

from tidy3d.plugins.mode import ModeSolver

Defining the Geometry¶

# global parameters

wl = 1.5

num_freqs = 1

freq0 = td.C_0 / wl

fwidth = 0.2 * freq0

freqs = [freq0] if num_freqs == 1 else np.linspace(freq0 - fwidth, freq0 + fwidth, num_freqs)

source_time = td.GaussianPulse(freq0=freq0, fwidth=fwidth)

symmetry = [0, 1, -1]

sim_center = (0, 0, 0)

run_time = 20e-12

# function for returning the waveguide as a function of length and plane size

def get_sim(length=10, plane_size=6, min_steps_per_wvl=15):

sim_size = (length, plane_size, plane_size)

structure_index = 1.99

background_index = 1.44

width = 0.33

height = 0.2

structure_medium = td.Medium(permittivity=structure_index**2)

background_medium = td.Medium(permittivity=background_index**2)

structure = td.Structure(

geometry=td.Box(center=(0, 0, 0), size=(td.inf, width, height)), medium=structure_medium

)

# source

mode_spec = td.ModeSpec(num_modes=1, precision="double")

source = td.ModeSource(

center=(-sim_size[0] / 2 + 0.5, 0, 0),

size=(0, plane_size, plane_size),

mode_spec=mode_spec,

direction="+",

mode_index=0,

source_time=source_time,

)

# flux monitor

flux_mon = td.FluxMonitor(

name="flux_mon",

size=(0, plane_size, plane_size),

center=(sim_size[0] / 2 - 0.5, 0, 0),

freqs=freqs,

)

# field monitor

field_mon = td.FieldMonitor(

name="field_mon",

size=(td.inf, td.inf, 0),

center=(0, 0, 0),

freqs=freqs,

)

# grid spec

grid_spec = td.GridSpec.auto(min_steps_per_wvl=min_steps_per_wvl)

sim = td.Simulation(

size=sim_size,

center=sim_center,

grid_spec=grid_spec,

structures=[structure],

sources=[source],

monitors=[flux_mon, field_mon],

run_time=run_time,

symmetry=symmetry,

medium=background_medium,

)

ms = ModeSolver(

mode_spec=source.mode_spec.updated_copy(num_pml=(12, 12)),

freqs=freqs,

simulation=sim,

plane=td.Box(size=(0, plane_size, plane_size), center=source.center),

)

return sim, ms

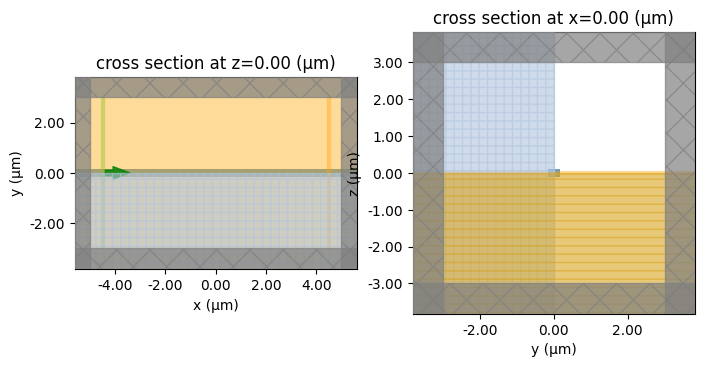

# plotting the simulation domain

sim, _ = get_sim()

fig, ax = plt.subplots(1, 2, figsize=(8, 8))

sim.plot(ax=ax[0], z=0)

sim.plot(ax=ax[1], x=0)

plt.show()

Mode Solver Analysis¶

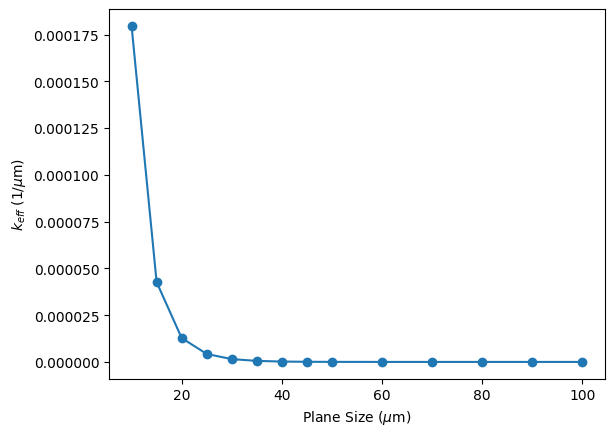

First, we will carry out ModeSolver simulations varying the plane size.

ms_list = {}

sizes = [10, 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100]

for size in sizes:

_, ms = get_sim(5, plane_size=size)

ms_list[str(size)] = ms

ms_batch = web.Batch(simulations=ms_list)

ms_data = ms_batch.run()

Output()

14:02:20 UTC Started working on Batch containing 14 tasks.

14:04:16 UTC Maximum FlexCredit cost: 0.135 for the whole batch.

Use 'Batch.real_cost()' to get the billed FlexCredit cost after completion.

Output()

14:10:34 UTC Batch complete.

Now, we can plot the imaginary part of the effective index as a function of the plane size. As we can see, for planes smaller than 60 µm, there are losses induced by the interaction of the evanescent fields with the simulation boundaries. These losses will lead to unphysical results for a long waveguide.

loss = [ms_data[str(i)].to_dataframe()["k eff"] for i in sizes]

fig, ax = plt.subplots()

ax.set_xlabel(r"Plane Size ($\mu$m)")

ax.set_ylabel(r"$k_{eff}$ (1/$\mu$m)")

ax.plot(sizes, loss, "-o")

plt.show()

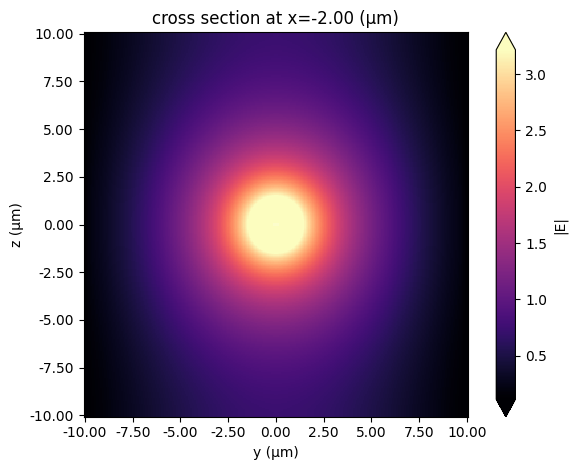

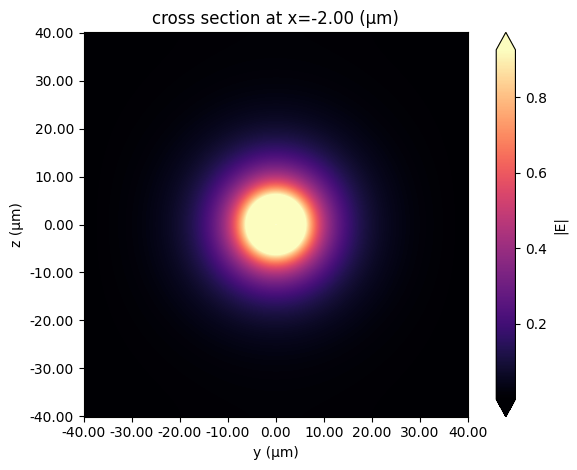

To illustrate the importance of a correct simulation domain size, we compare the mode profiles for plane sizes of 20 µm and 80 µm.

As we can see, in the 20 µm case, the fields extending into the PML are not negligible. In contrast, with an 80 µm plane size, the fields decay sufficiently before reaching the PML boundaries.

ms_list["20"].plot_field("E", "abs")

ms_list["80"].plot_field("E", "abs")

plt.show()

FDTD Simulation¶

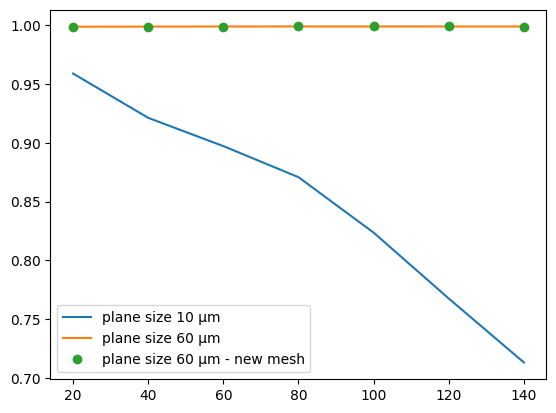

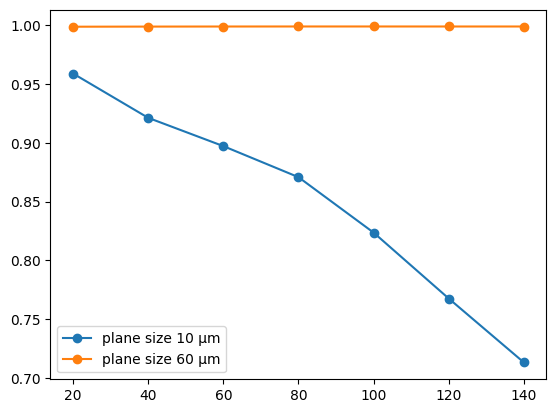

Now, we will simulate a relatively long waveguide with two different plane sizes: 10 µm and 60 µm. We will add FluxMonitors every 20 µm and observe the losses as a function of propagation.

sim_10, _ = get_sim(length=150, plane_size=10)

sim_60, _ = get_sim(length=150, plane_size=60)

monitors = []

positions = range(20, 150, 20)

for i in positions:

flux_mon = td.FluxMonitor(

name=f"flux_mon{i}",

size=(0, 50, 50),

center=(-sim_10.size[0] / 2 + i, 0, 0),

freqs=freqs,

)

monitors.append(flux_mon)

sim_10 = sim_10.updated_copy(monitors=monitors + [sim_10.monitors[-1]])

sim_60 = sim_60.updated_copy(monitors=sim_10.monitors)

batch = web.Batch(simulations={"10": sim_10, "60": sim_60})

batch_data = batch.run()

Output()

14:10:56 UTC Started working on Batch containing 2 tasks.

14:11:18 UTC Maximum FlexCredit cost: 29.441 for the whole batch.

Use 'Batch.real_cost()' to get the billed FlexCredit cost after completion.

Output()

14:13:58 UTC Batch complete.

As we can see, for the 10 µm plane size simulation, there are significant losses, although increasing the simulation size can significantly raise the simulation cost.

fig, ax = plt.subplots()

loss_10 = [batch_data["10"][f"flux_mon{i}"].flux for i in positions]

loss_60 = [batch_data["60"][f"flux_mon{i}"].flux for i in positions]

ax.plot(positions, loss_10, "o-", label="plane size 10 µm")

ax.plot(positions, loss_60, "o-", label="plane size 60 µm")

ax.legend()

plt.show()

cost_60 = web.real_cost(batch_data.task_ids["60"])

cost_10 = web.real_cost(batch_data.task_ids["10"])

print(f"Cost for plane size 10: {cost_10}")

print(f"Cost for plane size 60: {cost_60}")

14:14:03 UTC Billed flex credit cost: 2.789.

Note: the task cost pro-rated due to early shutoff was below the minimum threshold, due to fast shutoff. Decreasing the simulation 'run_time' should decrease the estimated, and correspondingly the billed cost of such tasks.

14:14:04 UTC Billed flex credit cost: 0.155.

Note: the task cost pro-rated due to early shutoff was below the minimum threshold, due to fast shutoff. Decreasing the simulation 'run_time' should decrease the estimated, and correspondingly the billed cost of such tasks.

Cost for plane size 10: 0.1548042128079098 Cost for plane size 60: 2.78931887161537

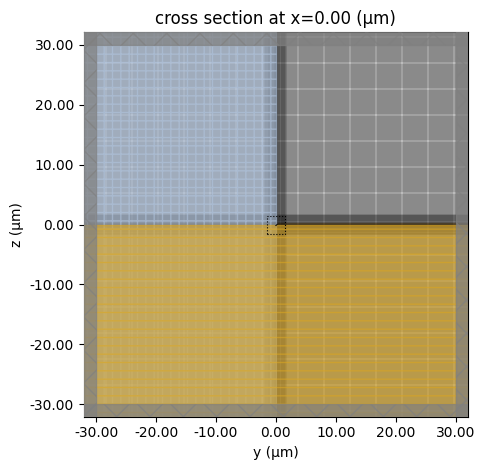

Custom Grid for Reducing Simulation Cost¶

To reduce simulation cost, we can use the minimum permitted value for the autogrid min_steps_per_wavelength argument, which is 6, and add a MeshOverrideRegion around the waveguide. This allows enough space for the fields to decay before reaching the simulation boundaries, while maintaining good resolution around the waveguide.

mesh_structure = sim_60.structures[0]

Si02_steps = (wl / 1.45) / 15

SiN_steps = (wl / 1.99) / 15

mesh_override_SiN = td.MeshOverrideStructure(

geometry=mesh_structure.geometry,

dl=(SiN_steps,) * 3,

)

mesh_override_SiO2 = td.MeshOverrideStructure(

geometry=td.Box(center=(0, 0, 0), size=(td.inf, 3, 3)),

dl=(Si02_steps,) * 3,

)

grid_spec = td.GridSpec.auto(

min_steps_per_wvl=6, override_structures=[mesh_override_SiO2, mesh_override_SiN]

)

sim_60_newMesh = sim_60.updated_copy(grid_spec=grid_spec)

ax = sim_60_newMesh.plot(x=0)

sim_60_newMesh.plot_grid(ax=ax, x=0)

plt.show()

task_id = web.upload(sim_60_newMesh, "sim_60_newMesh")

web.start(task_id)

web.monitor(task_id)

sim_data = web.load(task_id)

WARNING: Mode source at sources[0] has a large number (1.47e+05) of grid points. This can lead to solver slow-down and increased cost. Consider making the size of the component smaller, as long as the modes of interest decay by the plane boundaries.

Created task 'sim_60_newMesh' with resource_id 'fdve-48b2b0f3-df09-4766-9a30-517ef342149a' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-48b2b0f3-df0 9-4766-9a30-517ef342149a'.

Task folder: 'default'.

Output()

14:14:14 UTC Estimated FlexCredit cost: 7.807. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

14:14:16 UTC status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

14:14:27 UTC status = preprocess

14:14:51 UTC starting up solver

running solver

Output()

14:15:30 UTC early shutoff detected at 8%, exiting.

14:15:31 UTC status = postprocess

14:15:34 UTC status = success

14:15:36 UTC View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-48b2b0f3-df0 9-4766-9a30-517ef342149a'.

Output()

14:15:47 UTC Loading results from simulation_data.hdf5

# Here we will use the web API get_tasks to get the cost of the last simulation

cost_60_newMesh = web.real_cost(task_id)

print(f"Cost for plane size 60 with new mesh: {cost_60_newMesh}")

14:15:48 UTC Billed flex credit cost: 0.781.

Note: the task cost pro-rated due to early shutoff was below the minimum threshold, due to fast shutoff. Decreasing the simulation 'run_time' should decrease the estimated, and correspondingly the billed cost of such tasks.

Cost for plane size 60 with new mesh: 0.7806608694859469

As we can see, this meshing strategy returns very similar results, while consuming less than one-third of the Flexcredits.

loss_60_newMesh = [sim_data[f"flux_mon{i}"].flux for i in positions]

fig, ax = plt.subplots()

ax.plot(positions, loss_10, label="plane size 10 µm")

ax.plot(positions, loss_60, label="plane size 60 µm")

ax.plot(positions, loss_60_newMesh, "o", label="plane size 60 µm - new mesh")

ax.legend()

plt.show()