The microring modulator (MRR) is a key component in modern photonics design. In this notebook, we model the RF electrode in a silicon-on-insulator MRR, which carries the electrical signal responsible for optical modulation.

In a full fidelity model, the MRR would require multiphysics coupling of thermal, charge, optical, and RF simulations. For this RF-only demonstration, we will approximate the reverse bias p-n junction, responsible for the optical phase modulation, with a lumped RC element. The focus will be on minimizing return loss within the operational bandwidth.

import gdstk

import matplotlib.pyplot as plt

import numpy as np

import tidy3d as td

import tidy3d.rf as rf

from tidy3d import web

td.config.logging.level = "ERROR"

Building the Model¶

Key Parameters and Materials¶

The bandwidth of the simulation is 10-100 GHz.

# Frequency bandwidth

f_min, f_max = (10e9, 100e9)

f0 = (f_max + f_min) / 2

freqs = np.linspace(f_min, f_max, 101)

# Dimensions

len_inf = 1e5

bounds_electrode = (2.62, 3.02)

bounds_oxide = (-3.017, 2.62)

bounds_sub = (-len_inf, -3.017)

TM = bounds_electrode[1] - bounds_electrode[0] # electrode thickness

The equivalent RC parameters of the reverse bias p-n junction can be estimated using a lumped circuit model. Details of the calculation are presented in section 2.2.3 of Ref [1].

# Lumped electrical parameters

C_lumped = 17.325e-15 # Farads

R_lumped = 113.12 # Ohms

Zref = 50 # Ohms, port reference impedance

The relevant materials are defined below.

# Mediums

med_sub = td.Medium(permittivity=12.3) # Si substrate

med_oxide = td.Medium(permittivity=4.2) # SiO2

med_metal = rf.LossyMetalMedium(conductivity=17, frequency_range=(f_min, f_max)) # Metal [S/um]

Geometry¶

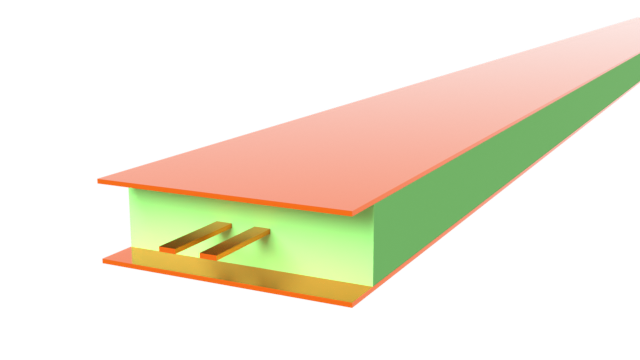

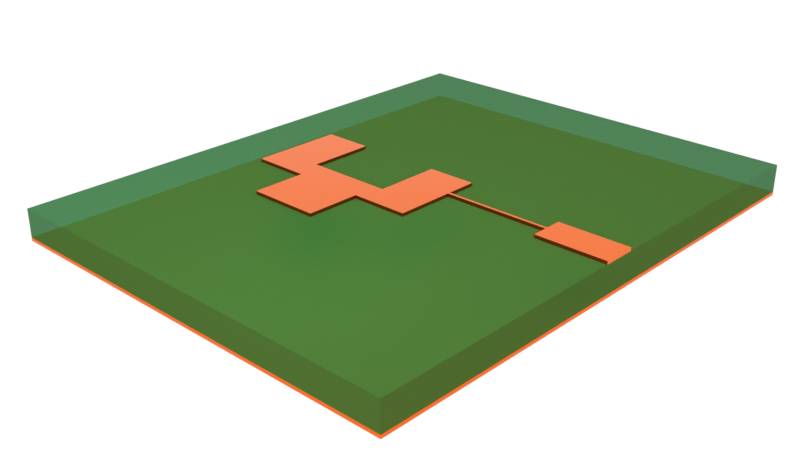

In lieu of building the electrode geometry from scratch, we will import a pre-constructed 2D shape from GDS. It is then extruded to the appropriate thickness. For more details on working with GDS files, see this tutorial.

# Load GDS and build metal electrode geometry

gds_mmr = gdstk.read_gds("misc/mrr-electrode.gds")

g_electrode = td.Geometry.from_gds(

gds_mmr["MRR"], gds_layer=12, gds_dtype=0, slab_bounds=bounds_electrode, axis=2

)

# Dielectric layers

g_oxide = td.Box.from_bounds(

rmin=(-len_inf, -len_inf, bounds_oxide[0]), rmax=(len_inf, len_inf, bounds_oxide[1])

)

g_sub = td.Box.from_bounds(

rmin=(-len_inf, -len_inf, bounds_sub[0]), rmax=(len_inf, len_inf, bounds_sub[1])

)

The geometries are combined with the corresponding mediums into Structure instances below.

# Structures

str_sub = td.Structure(geometry=g_sub, medium=med_sub)

str_oxide = td.Structure(geometry=g_oxide, medium=med_oxide)

str_electrode = td.Structure(geometry=g_electrode, medium=med_metal)

structure_list = [str_sub, str_oxide, str_electrode]

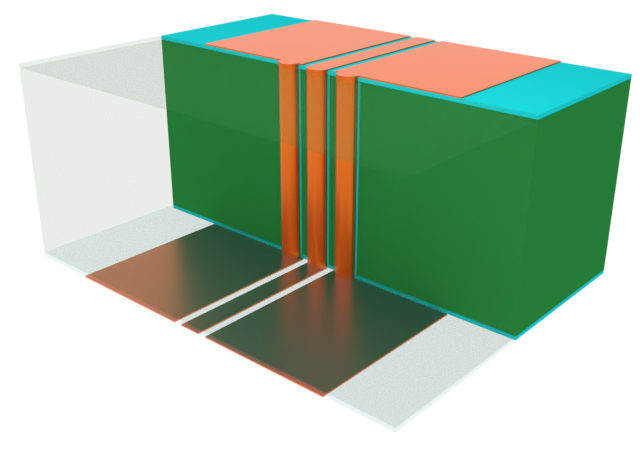

Grid and Boundary¶

The external boundaries of the simulation are terminated with Perfectly Matched Layers (PMLs) by default. We add some space padding around the electrode, although we do not expect it to radiate significantly.

# Simulation center and size

sim_X0, sim_Y0, sim_Z0 = (30, -30, 0)

sim_LX, sim_LY, sim_LZ = (450, 300, 400)

The grid should be able to resolve key features in the electrode, such as the gap and corners, for accurate results. To this end, we use the LayerRefinementSpec feature to automatically analyze the electrode geometry and generate an appropriately fine mesh. For added fidelity, we also define a MeshOverrideStructure around the microring region that constrains maximum grid size in the in-plane directions.

# Layer refinement

lr1 = rf.LayerRefinementSpec.from_structures(

structures=[str_electrode],

corner_refinement=td.GridRefinement(dl=1, num_cells=2),

min_steps_along_axis=1,

)

# Mesh override

refine_box = td.MeshOverrideStructure(

geometry=td.Box.from_bounds(

rmin=(16.5, 1, bounds_electrode[0]), rmax=(43.5, 27, bounds_electrode[1])

),

dl=(1, 1, None),

)

The overall grid specification is defined below. The rest of the simulation grid is automatically generated based on the shortest wavelength.

# Grid specification

grid_spec = td.GridSpec.auto(

min_steps_per_wvl=12,

wavelength=td.C_0 / f_max,

layer_refinement_specs=[lr1],

override_structures=[refine_box],

)

Monitors¶

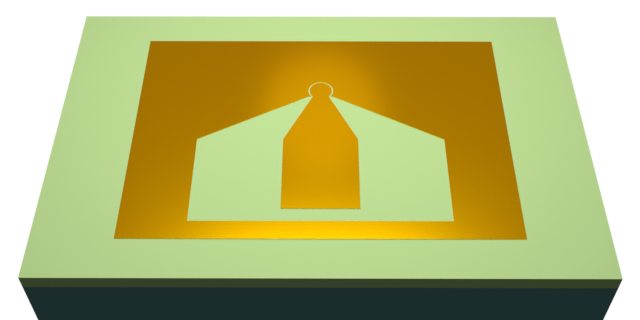

We define a field monitor just below the electrode plane for visualization purposes.

# Field Monitor

mon_1 = td.FieldMonitor(

center=(sim_X0, sim_Y0, bounds_electrode[0]),

size=(len_inf, len_inf, 0),

freqs=[f_min, f0, f_max],

name="field in-plane",

)

monitor_list = [mon_1]

Lumped Ports and Elements¶

We will use lumped ports and elements in this model since the structure is extremely sub-wavelength.

# Lumped port

LP1 = rf.LumpedPort(

center=(30, -85, bounds_electrode[1]),

size=(60, 10, 0),

voltage_axis=1,

name="LP1",

impedance=Zref,

)

The equivalent RC circuit representing the p-n junction is defined below.

# Lumped element (RC network)

lumped_network = rf.RLCNetwork(resistance=R_lumped, capacitance=C_lumped, network_topology="series")

LE1 = rf.LinearLumpedElement(

center=(30, 24.795, bounds_electrode[1]),

size=(2, 2.2, 0),

voltage_axis=1,

network=lumped_network,

name="LumpedRC",

)

Simulation and TerminalComponentModeler¶

The simulation and TerminalComponentModeler instances are defined below.

sim = td.Simulation(

center=(sim_X0, sim_Y0, sim_Z0),

size=(sim_LX, sim_LY, sim_LZ),

grid_spec=grid_spec,

structures=structure_list,

monitors=monitor_list,

lumped_elements=[LE1],

run_time=1e-10,

)

tcm = rf.TerminalComponentModeler(

simulation=sim,

ports=[LP1],

freqs=freqs,

)

Visualization¶

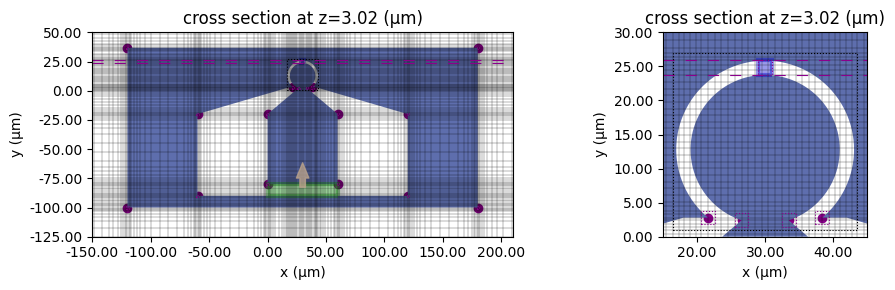

Before running the simulation, let us visualize the geometry and grid. The lumped port (green) and lumped RC element (blue) are also depicted below.

# Metal electrode plane

fig, ax = plt.subplots(1, 2, figsize=(10, 3), tight_layout=True)

tcm.simulation.plot_grid(z=bounds_electrode[1], ax=ax[0])

tcm.plot_sim(z=bounds_electrode[1], ax=ax[0], monitor_alpha=0, hlim=(-150, 210), vlim=(-125, 50))

tcm.simulation.plot_grid(z=bounds_electrode[0], ax=ax[1])

tcm.plot_sim(z=bounds_electrode[1], ax=ax[1], monitor_alpha=0, hlim=(15, 45), vlim=(0, 30))

plt.show()

We can also use the 3D viewer.

sim.plot_3d()

Running the Simulation¶

The simulation is executed below.

tcm_data = web.run(tcm, task_name="microring_electrode", path="data/microring_electrode.hdf5")

15:29:00 EST Created task 'microring_electrode' with resource_id 'sid-6857c885-b3a5-4037-9712-a7d128ef7ec5' and task_type 'TERMINAL_CM'.

View task using web UI at 'https://tidy3d.simulation.cloud/rf?taskId=pa-f69572f7-2ab1-4c96-bd 5b-1574ec339f7e'.

Task folder: 'default'.

Output()

15:29:08 EST Maximum FlexCredit cost: 0.113. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' after run.

Subtasks status - microring_electrode Group ID: 'pa-f69572f7-2ab1-4c96-bd5b-1574ec339f7e'

Output()

Batch status = preprocess

15:29:15 EST Batch status = running

15:49:14 EST Batch status = postprocess

15:49:27 EST Modeler has finished running successfully.

Billed flex credit cost: 0.059.

Output()

15:49:29 EST Loading component modeler data from data/microring_electrode.hdf5

Results¶

S-parameter¶

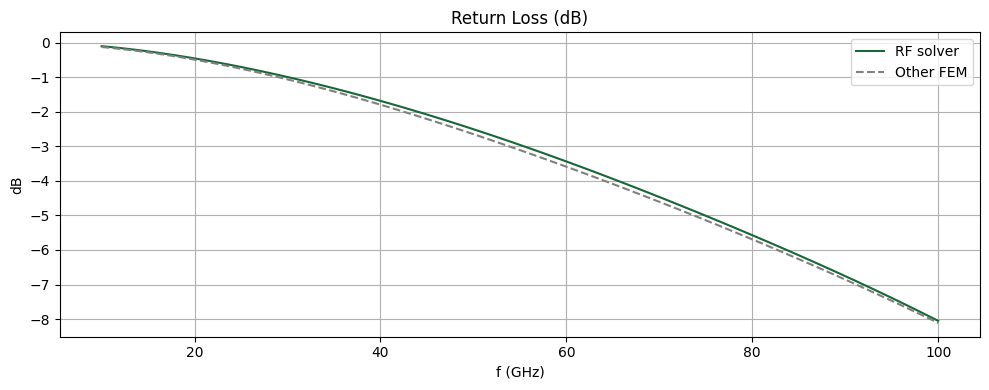

We extract S11 below. For comparison purposes, we also import benchmark data from a commercial FEM solver based on a similar setup.

# Extract S11

smat = tcm_data.smatrix().data

S11 = np.conjugate(smat.squeeze())

# Import benchmark data

freqs_ben, S11dB_ben = np.genfromtxt(

"misc/mrr_fem_sparam.csv", delimiter=",", skip_header=1, unpack=True

)

The return loss (RL) is shown below. We find very good agreement with the benchmark. From the RL plot, we observe that the electrode has a -3 dB bandwidth of up to 55 GHz.

# Plot return loss

fig, ax = plt.subplots(figsize=(10, 4), tight_layout=True)

ax.plot(freqs / 1e9, 20 * np.log10(np.abs(S11)), label="RF solver")

ax.plot(freqs_ben, S11dB_ben, ls="--", color="gray", label="Other FEM")

ax.set_title("Return Loss (dB)")

ax.set_ylabel("dB")

ax.set_xlabel("f (GHz)")

ax.grid()

ax.legend()

plt.show()

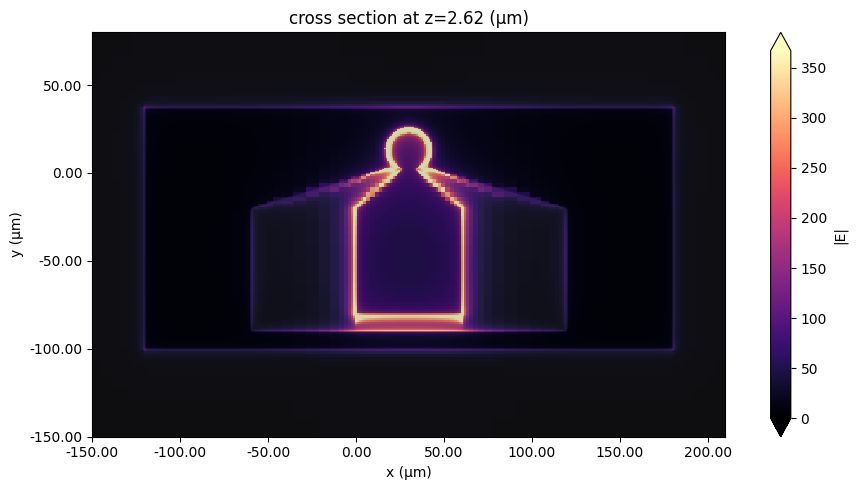

Field profile¶

We extract the field monitor data and plot the in-plane field magnitude at the center frequency below.

# Extract monitor data

sim_data = tcm_data.data["LP1"]

# Plot field monitor data

fig, ax = plt.subplots(figsize=(10, 5), tight_layout=True)

f_plot = f0

sim_data.plot_field("field in-plane", field_name="E", val="abs", f=f_plot, ax=ax)

ax.set_xlim(-150, 210)

ax.set_ylim(-150, 80)

plt.show()

Reference¶

[1] Wang, Zhao. "Silicon micro-ring resonator modulator for inter/intra-data centre applications." PhD diss., 2017.