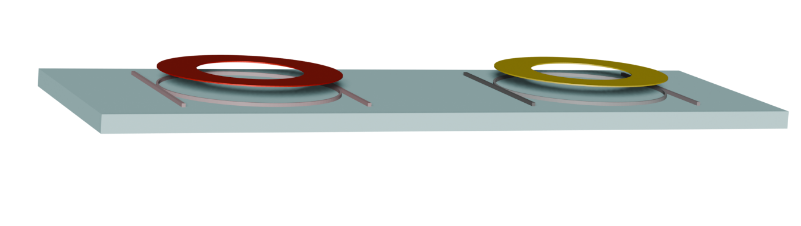

In this example, we will simulate a thin-film lithium niobate electro-optic modulator based on the Pockels effect. The device is based on the work of *Ying Li et al.*, “High-Performance Mach–Zehnder Modulator Based on Thin-Film Lithium Niobate with Low Voltage-Length Product,” *ACS Omega* 2023, 8 (10), 9644–9651. DOI: 10.1021/acsomega.3c00310.

We start by calculating the propagating modes of the TFLN waveguide and the coplanar (CPW) transmission line using mode simulation.

Finally, we calculate the electro-optic overlap and predict the Vπ·L figure of merit.

You can check here the same model, along with the full chip layout integrated with a foundry PDK, using Photonforge, our photonic design automation tool.

Workflow Overview¶

1. Define the thin-film lithium niobate waveguide geometry and solve for the optical TE mode using the ModeSolver.

2. Build the CPW transmission line in the same cross-section and compute the RF mode and its overlap with the optical waveguide.

3. Normalize the RF field to 1 V across the electrodes, evaluate the electro-optic overlap, and estimate Vπ·L.

# Core simulation and plotting libraries

import numpy as np

import tidy3d as td

# RF utilities for impedance and port definitions

import tidy3d.rf as rf

from matplotlib import pyplot as plt

from tidy3d import web

from tidy3d.plugins.mode import ModeSolver

# Suppress verbose logs to keep the notebook output clear

td.config.logging_level = "ERROR"

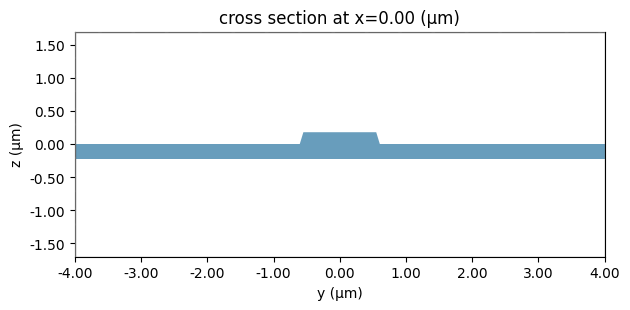

Optical Waveguide Geometry ¶

# Simulation parameters

eff_inf = 1e3 # Large extent to emulate semi-infinite regions

opt_wavelength = 1.55

freq_opt = td.C_0 / opt_wavelength

# Optical materials: SiO2 cladding and TFLN core

SiO2 = td.material_library["SiO2"]["Palik_Lossless"]

LiNbO3 = td.material_library["LiNbO3"]["Zelmon1997"](1)

# Ridge geometry parameters from the reference design

sidewall_angle = 17

core_width = 1.1 # w0

slab_thickness = 0.22 # h3

h3 = slab_thickness

core_thickness = 0.4 - slab_thickness

plane_size = 8

plane_limits = (-1.5, 1.9)

plane_height = 3.4

# Define waveguide structures

ridge = td.Structure(

name="ridge",

geometry=td.Box(

center=(0.0, 0.0, -slab_thickness / 2), size=(eff_inf, eff_inf, slab_thickness)

),

medium=LiNbO3,

)

core = td.Structure(

geometry=td.PolySlab(

sidewall_angle=sidewall_angle * np.pi / 180,

reference_plane="top",

slab_bounds=[0, core_thickness],

vertices=[

[-eff_inf, -core_width / 2],

[eff_inf, -core_width / 2],

[eff_inf, core_width / 2],

[-eff_inf, core_width / 2],

],

),

name="core",

medium=LiNbO3,

)

# Grid specification

grid_spec = td.GridSpec.auto(min_steps_per_wvl=20, wavelength=opt_wavelength)

# Create optical simulation

sim_opt = td.Simulation(

size=(10.0, plane_size, plane_height),

run_time=1e-12,

medium=SiO2,

structures=[ridge, core],

grid_spec=grid_spec,

)

Creating the ModeSolver object and running the mode simulation¶

## Creating the ModeSolver

mode_spec = td.ModeSpec(num_modes=5, group_index_step=True)

plane_size = (0, sim_opt.bounding_box.size[1], sim_opt.bounding_box.size[2])

plane = sim_opt.bounding_box.updated_copy(size=plane_size)

mode_solver_opt = ModeSolver(simulation=sim_opt, freqs=[freq_opt], mode_spec=mode_spec, plane=plane)

_ = mode_solver_opt.plot()

plt.show()

mode_data_opt = web.run(mode_solver_opt, task_name="TFLN-opt_mode", folder_name="TFLN-VPI")

15:08:20 EST Created task 'TFLN-opt_mode' with resource_id 'mo-8e2b4865-7943-4fee-93a0-ba812e41d7d9' and task_type 'MODE_SOLVER'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-8e2b4865-7943- 4fee-93a0-ba812e41d7d9'.

Task folder: 'TFLN-VPI'.

Output()

15:08:30 EST Estimated FlexCredit cost: 0.005. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

15:08:31 EST status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

Output()

15:09:31 EST starting up solver

running solver

15:09:39 EST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-8e2b4865-7943- 4fee-93a0-ba812e41d7d9'.

Output()

15:09:42 EST Loading simulation from simulation_data.hdf5

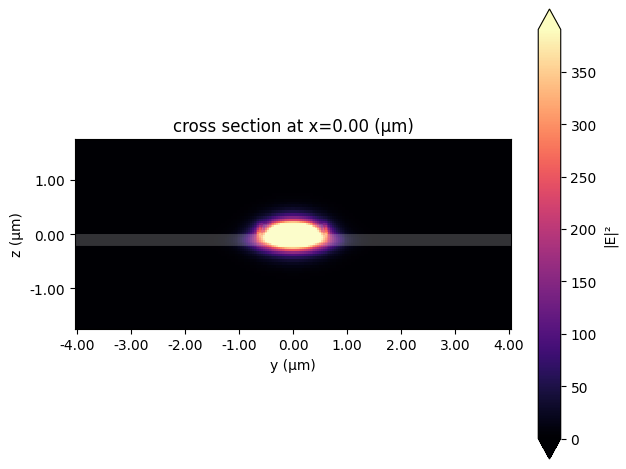

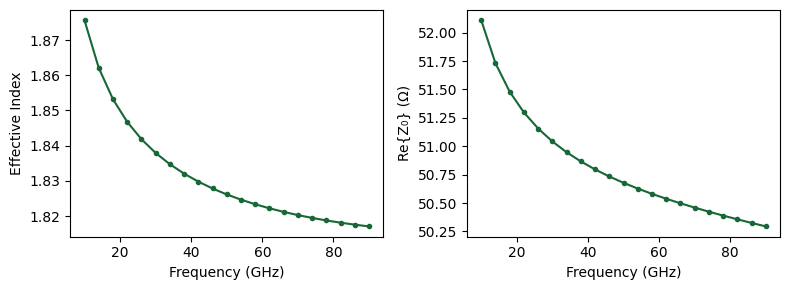

We can now visualize and inspect the optical modes. We are interested in the TE-like fundamental mode (with mode_index == 0), which has an effective index of 1.85 and a group index of 2.20. This information is very important to ensure velocity matching between the optical and RF modes, and hence optimize the electro-optical effect.

mode_solver_opt.plot_field("E", "abs^2", mode_index=0)

mode_data_opt.to_dataframe()

plt.show()

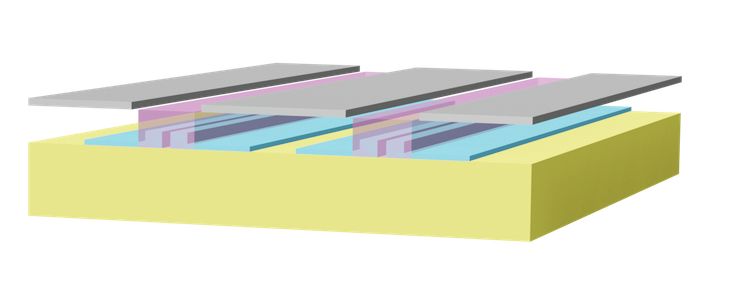

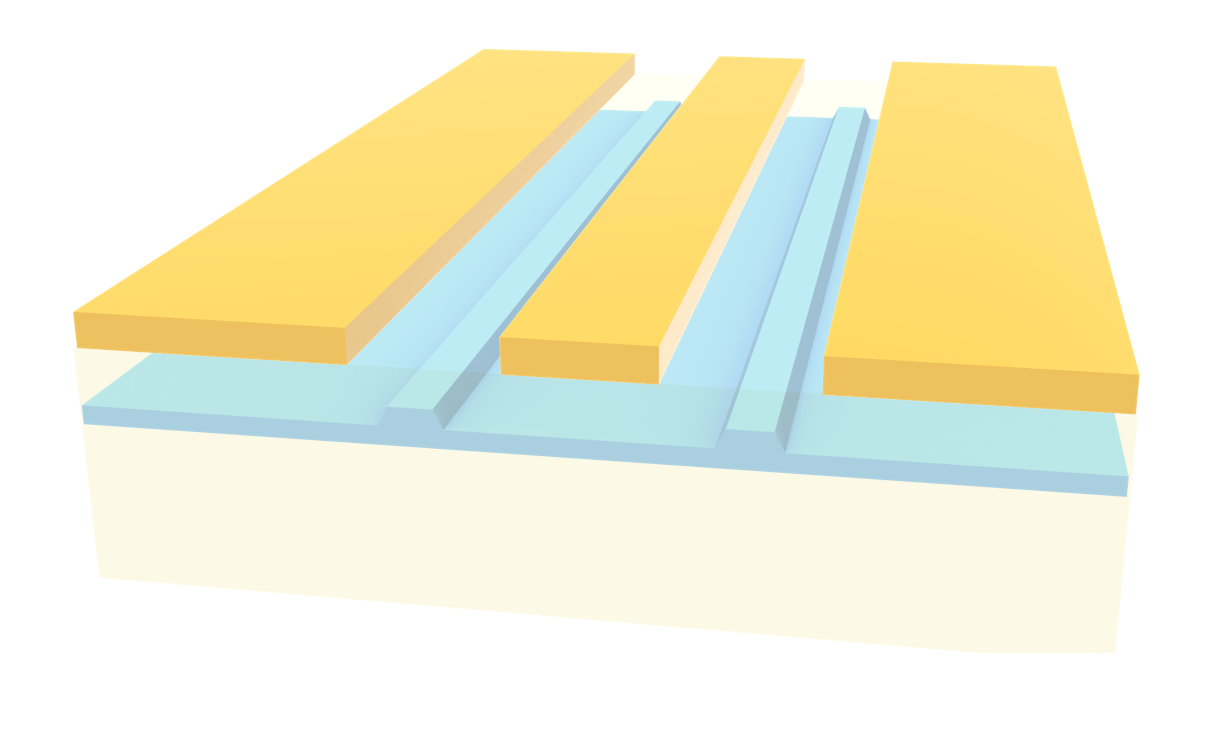

RF CPW Transmission Line ¶

Next, we define the CPW geometry and again use ModeSolver to calculate the RF mode.

For more information on CPW mode calculation, one can refer to this example.

# RF frequency range

rf_freqs = np.linspace(10e9, 90e9, 21)

# RF materials

si_rf = td.Medium(permittivity=11.7)

sio2_rf = td.Medium(permittivity=3.9)

air_rf = td.Medium()

tfln_rf = td.AnisotropicMedium(

xx=td.Medium(permittivity=43), yy=td.Medium(permittivity=27.9), zz=td.Medium(permittivity=43)

)

metal = td.LossyMetalMedium(

frequency_range=(100000000.0, 100000000000.0),

conductivity=41,

fit_param=td.SurfaceImpedanceFitterParam(

max_num_poles=16,

),

)

Since we will sweep over many variables, it is convenient to create a function to return the CPW and optical waveguide geometries.

def get_structures(

h4=4.7,

h2=0.4,

h1=1,

cpw_thickness=1, # CPW geometry parameters

cpw_width=18, # w1

cpw_gap=5, # g

optical_waveguide_gap=25,

): # G

sio2_thickness = h1 + h3 + h4

si_substrate = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -eff_inf, -eff_inf), rmax=(eff_inf, eff_inf, -sio2_thickness / 2)

),

medium=si_rf,

)

# Define substrate and layer structures

sio2_slab = td.Structure(

geometry=td.Box(center=(0, 0, 0), size=(eff_inf, eff_inf, sio2_thickness)), medium=sio2_rf

)

# Optical waveguide

center_slab = sio2_slab.geometry.bounds[0][2] + h4 + slab_thickness / 2

tfln_slab = td.Structure(

geometry=td.Box(center=(0, 0, center_slab), size=(eff_inf, eff_inf, slab_thickness)),

medium=tfln_rf,

)

# Calculate vertical offset to position waveguides at TFLN slab level

delta_z = tfln_slab.geometry.center[2] - ridge.geometry.center[2]

# Define conformal cladding for waveguides

delta_z_conformal = sio2_slab.geometry.bounds[1][2]

waveguide_conformal_cladding = td.PolySlab(

sidewall_angle=sidewall_angle * np.pi / 180,

reference_plane="top",

slab_bounds=[delta_z_conformal, delta_z_conformal + core_thickness],

vertices=[

[-eff_inf, -core_width / 1.5],

[eff_inf, -core_width / 1.5],

[eff_inf, core_width / 1.5],

[-eff_inf, core_width / 1.5],

],

)

# Define right waveguide positioned under CPW gap

waveguide_r = [

ridge.updated_copy(

geometry=ridge.geometry.translated(

x=0, y=optical_waveguide_gap / 2 + core_width / 2, z=delta_z

),

name="ridge_r",

medium=tfln_rf,

),

core.updated_copy(

geometry=core.geometry.translated(

x=0, y=optical_waveguide_gap / 2 + core_width / 2, z=delta_z

),

name="core_r",

medium=tfln_rf,

),

td.Structure(

geometry=waveguide_conformal_cladding.translated(

x=0, y=optical_waveguide_gap / 2 + core_width / 2, z=0

),

medium=sio2_rf,

),

]

# Define left waveguide positioned under CPW gap

waveguide_l = [

ridge.updated_copy(

geometry=ridge.geometry.translated(

x=0, y=-optical_waveguide_gap / 2 - core_width / 2, z=delta_z

),

name="ridge_l",

medium=tfln_rf,

),

core.updated_copy(

geometry=core.geometry.translated(

x=0, y=-optical_waveguide_gap / 2 - core_width / 2, z=delta_z

),

name="core_l",

medium=tfln_rf,

),

td.Structure(

geometry=waveguide_conformal_cladding.translated(

x=0, y=-optical_waveguide_gap / 2 - core_width / 2, z=0

),

medium=sio2_rf,

),

]

cpw_center_pos = sio2_slab.geometry.bounds[1][2] + cpw_thickness / 2

# Define CPW transmission line structures

cpw_left = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -eff_inf, cpw_center_pos - cpw_thickness / 2),

rmax=(eff_inf, -cpw_width / 2 - cpw_gap, cpw_center_pos + cpw_thickness / 2),

),

medium=metal,

)

cpw_right = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, cpw_width / 2 + cpw_gap, cpw_center_pos - cpw_thickness / 2),

rmax=(eff_inf, eff_inf, cpw_center_pos + cpw_thickness / 2),

),

medium=metal,

)

cpw_center = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -cpw_width / 2, cpw_center_pos - cpw_thickness / 2),

rmax=(eff_inf, cpw_width / 2, cpw_center_pos + cpw_thickness / 2),

),

medium=metal,

)

air_gap = td.Structure(

geometry=td.Box.from_bounds(

rmin=(-eff_inf, -eff_inf, sio2_thickness / 2), rmax=(eff_inf, eff_inf, eff_inf)

),

medium=air_rf,

)

return (

[sio2_slab, si_substrate, air_gap, cpw_left, cpw_right, cpw_center, tfln_slab]

+ waveguide_l

+ waveguide_r

)

structures = get_structures()

def get_sim(

h4=4.7, # top SiO2 cladding thickness (µm)

h2=0.4,

h1=1, # lower layer thickness beneath the electrodes (µm)

cpw_thickness=1, # CPW geometry parameters (t)

cpw_width=18, # w1

cpw_gap=5,

optical_waveguide_gap=23 - core_width / 2, # G

refinement=10,

resolution=30,

fields=["Ex", "Ey", "Ez", "Hx", "Hy", "Hz"],

): # g)

structures = get_structures(

h4, h2, h1, cpw_thickness, cpw_width, cpw_gap, optical_waveguide_gap

)

# Define layer refinement specification for enhanced mesh at CPW corners

cpw_center = structures[5]

cpw_left = structures[3]

cpw_right = structures[4]

tfln_slab = structures[6]

lr_spec = td.LayerRefinementSpec.from_structures(

structures=[cpw_center, cpw_left, cpw_right],

min_steps_along_axis=5,

corner_refinement=td.GridRefinement(dl=cpw_thickness / refinement, num_cells=5),

refinement_inside_sim_only=False,

)

# Mesh override for waveguide region (fine mesh in z-direction)

override_region = td.MeshOverrideStructure(

geometry=td.Box(

size=(eff_inf, eff_inf, slab_thickness + core_thickness),

center=(0, 0, tfln_slab.geometry.center[2] + slab_thickness / 2),

),

dl=(None, None, 0.05),

)

# Calculate gap center position

gap_center = cpw_center.geometry.center[1] + cpw_width / 2 + cpw_gap / 2

# Mesh override for left CPW gap (fine mesh in y-direction)

override_region_gap_l = td.MeshOverrideStructure(

geometry=td.Box(size=(eff_inf, cpw_gap, eff_inf), center=(0, gap_center, 0)),

dl=(None, 0.05, None),

)

# Mesh override for right CPW gap (fine mesh in y-direction)

override_region_gap_r = td.MeshOverrideStructure(

geometry=td.Box(size=(eff_inf, cpw_gap, eff_inf), center=(0, -gap_center, 0)),

dl=(None, 0.05, None),

)

# Overall grid specification

grid_spec = td.GridSpec.auto(

min_steps_per_sim_size=resolution,

wavelength=td.C_0 / max(rf_freqs),

layer_refinement_specs=[lr_spec],

override_structures=[override_region, override_region_gap_l, override_region_gap_r],

)

# Integration paths for impedance calculation

# Define current integration path (loop around CPW signal)

I_int = rf.AxisAlignedCurrentIntegral(

center=cpw_center.geometry.center,

size=(

0,

cpw_width + cpw_gap,

5 * cpw_thickness,

),

sign="+",

)

# Define voltage integration path (line from signal to ground)

V_int = rf.AxisAlignedVoltageIntegral(

center=(0, cpw_width / 2 + cpw_gap / 2, cpw_center.geometry.center[2]),

size=(0, cpw_gap, 0),

sign="-",

)

# Simulation domain size

sim_rf_size = (25, 138, 150)

# Create RF simulation

sim_vpi = td.Simulation(

size=sim_rf_size,

structures=structures,

grid_spec=grid_spec,

run_time=1e-12,

)

# Create and visualize the mode solver

plane = td.Box(

center=cpw_center.geometry.center,

size=(0, sim_vpi.size[1], sim_vpi.size[2]),

)

mzm_solver = ModeSolver(

simulation=sim_vpi,

plane=plane,

mode_spec=td.ModeSpec(num_modes=1, target_neff=2.2),

freqs=rf_freqs,

fields=fields,

)

return sim_vpi, mzm_solver, I_int, V_int

sim_vpi, mzm_solver, I_int, V_int = get_sim()

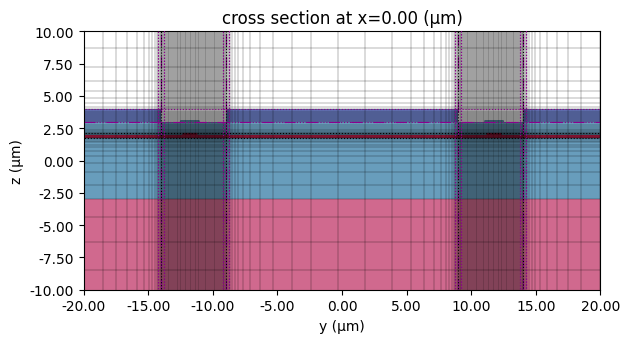

# Visualize the mesh

ax = mzm_solver.plot()

mzm_solver.plot_grid(ax=ax)

center = mzm_solver.simulation.structures[0].geometry.center

ax.set_xlim(center[0] - 20, center[0] + 20)

ax.set_ylim(center[1] - 10, center[1] + 10)

plt.show()

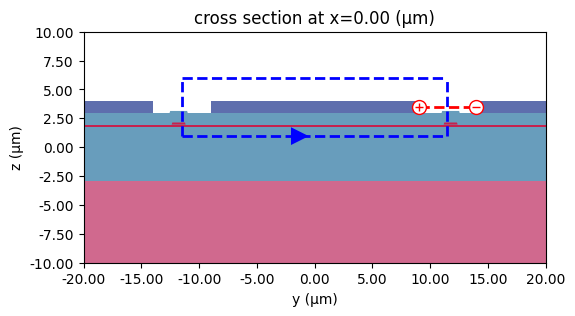

# Plot V and I integration paths

fig, ax = plt.subplots(figsize=(10, 3))

mzm_solver.plot(ax=ax)

I_int.plot(x=0, ax=ax)

V_int.plot(x=0, ax=ax)

ax.set_xlim(-20, 20)

ax.set_ylim(-10, 10)

plt.show()

Simulation Definition¶

Now, we define a function to can create the Simulation and ModeSolver objects.

Since the RF wavelength is much larger than the geometric features, we use a LayerRefinementSpec at the CPW to automatically enhance the mesh and better resolve its corners.

For the rest of the simulation, we use the automatic grid with min_steps_per_sim_size = 100, which ensures at least 100 grid cells along the longest dimension of the simulation domain.

We will also add mesh override regions to properly resolve the thickness of the optical waveguide, as well as the gaps, to ensure accurate results.

For impedance calculation, we define a current integration path around the CPW signal, and a voltage integration path from the signal to ground.

mzm_mode_data = web.run(mzm_solver, task_name="MZM mode solver", path="data/MZM_mode_data.hdf5")

15:09:43 EST Created task 'MZM mode solver' with resource_id 'mo-25e66852-c762-4ea5-b522-e33aec584e4c' and task_type 'MODE_SOLVER'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-25e66852-c762- 4ea5-b522-e33aec584e4c'.

Task folder: 'default'.

Output()

15:09:53 EST Estimated FlexCredit cost: 0.008. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

15:09:54 EST status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:10:24 EST starting up solver

running solver

15:10:30 EST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-25e66852-c762- 4ea5-b522-e33aec584e4c'.

Output()

15:10:33 EST Loading simulation from data/MZM_mode_data.hdf5

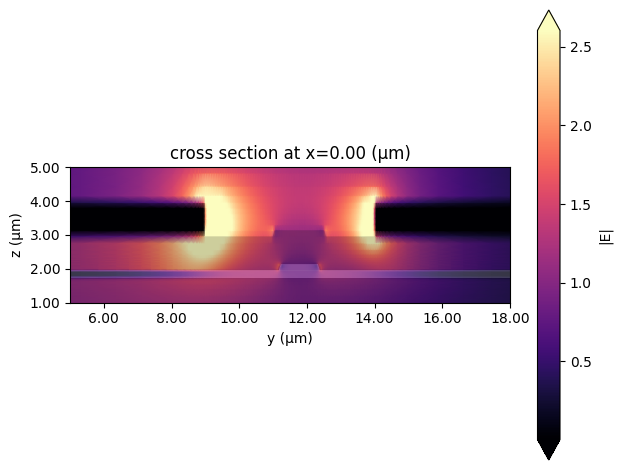

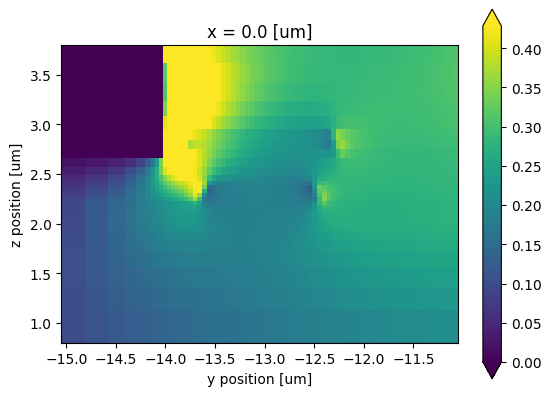

Visualizing the results:

# Visualize the RF mode

ax = mzm_solver.plot_field("E", "abs", f=rf_freqs[0], mode_index=0, robust=True, shading="gouraud")

ax.set_ylim(1, 5)

ax.set_xlim(5, 18)

plt.show()

We can now use the built-in ImpedanceCalculator to calculate and visualize the impedance results.

def get_impedance(data, I_int, V_int, plot=True):

n_eff = data.n_eff.isel(mode_index=0)

k_eff = data.k_eff.isel(mode_index=0)

# Calculate Z0

Z0_mzm = np.conjugate(

rf.ImpedanceCalculator(voltage_integral=V_int, current_integral=I_int).compute_impedance(

data

)

).squeeze()

if plot:

fig, ax = plt.subplots(1, 2, figsize=(8, 3), tight_layout=True)

ax[0].plot(rf_freqs * 1e-9, n_eff, ".-")

ax[0].set(ylabel="Effective Index", xlabel="Frequency (GHz)")

ax[1].plot(rf_freqs * 1e-9, np.real(Z0_mzm), ".-")

_ = ax[1].set(ylabel="Re{Z₀} (Ω)", xlabel="Frequency (GHz)")

return Z0_mzm, n_eff, k_eff

Z0_mzm, n_eff, k_eff = get_impedance(mzm_solver.data, I_int, V_int)

plt.show()

Sweep Over Different Parameters¶

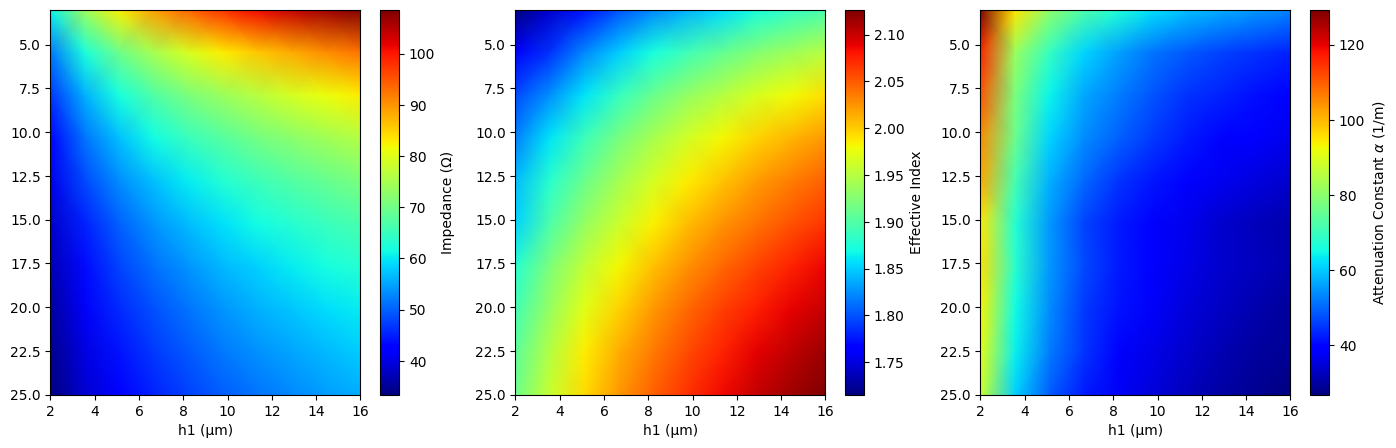

Now, we can sweep over different g and w1 parameters, and calculate impedance, effective index and attenuation constant

g_values = np.linspace(2, 16, 10)

w1_values = np.linspace(3, 25, 10)

dict = {}

dic_integrals = {}

for g in g_values:

for w1 in w1_values:

sim_vpi, mzm_solver, I_int, V_int = get_sim(

cpw_gap=g,

cpw_width=w1,

h4=2,

h1=1,

optical_waveguide_gap=w1 + g / 2,

fields=["Ey", "Hy", "Hz"],

) # Fields for calculating impedance

dict[f"({g:.2f},{w1:.2f})"] = mzm_solver

dic_integrals[f"({g:.2f},{w1:.2f})"] = I_int, V_int

batch = web.Batch(simulations=dict, folder_name="mzm_solver")

batch_data = batch.run(path_dir="batch_mzm_solver")

Output()

15:12:12 EST Started working on Batch containing 100 tasks.

15:24:43 EST Maximum FlexCredit cost: 0.895 for the whole batch.

Use 'Batch.real_cost()' to get the billed FlexCredit cost after completion.

Output()

15:26:19 EST Batch complete.

15:26:38 EST Loading simulation from batch_mzm_solver/mo-5f3a4c62-5f3b-49b3-83f4-c11b4cb70745.hdf5

Loading simulation from batch_mzm_solver/mo-8996fb52-6fd5-4659-b827-f088f79b0efb.hdf5

Loading simulation from batch_mzm_solver/mo-b1113f7e-2938-4d06-89ec-f220e86dcf0d.hdf5

15:26:39 EST Loading simulation from batch_mzm_solver/mo-1959b6a0-a5ec-4045-a1c9-786204b7d4ae.hdf5

Loading simulation from batch_mzm_solver/mo-31ac7023-db69-4cce-b4df-fc0675a8a443.hdf5

Loading simulation from batch_mzm_solver/mo-7d02415a-150e-4fe5-a416-a00afd01c0c4.hdf5

15:26:40 EST Loading simulation from batch_mzm_solver/mo-337b5a46-fb06-48d2-ab14-2ae55863b366.hdf5

Loading simulation from batch_mzm_solver/mo-245709a0-9a56-4253-a6e6-34e4f7976803.hdf5

Loading simulation from batch_mzm_solver/mo-c3f94b71-a878-49bc-a700-14bb85d723ef.hdf5

15:26:41 EST Loading simulation from batch_mzm_solver/mo-9075119b-a1bb-459a-bfab-706b6d41baed.hdf5

Loading simulation from batch_mzm_solver/mo-f2355ffe-288d-4ccf-9247-cbab9f04ebbd.hdf5

Loading simulation from batch_mzm_solver/mo-32620ef9-4d0e-4277-8c68-12f65c1838a9.hdf5

Loading simulation from batch_mzm_solver/mo-305b6a77-75cf-44b9-b3d3-8e77588db942.hdf5

15:26:42 EST Loading simulation from batch_mzm_solver/mo-d10ad170-4603-4dc1-8339-a15ac9d01dd6.hdf5

Loading simulation from batch_mzm_solver/mo-e8632d12-e314-426d-afd7-0d76836c92d4.hdf5

Loading simulation from batch_mzm_solver/mo-f38f0f2c-4725-4901-ac0b-a1483493c321.hdf5

15:26:43 EST Loading simulation from batch_mzm_solver/mo-d9b80b71-a105-42f1-8055-cbd331dbebeb.hdf5

Loading simulation from batch_mzm_solver/mo-dd59db5a-a7f3-4411-8f63-dabe5e2aa012.hdf5

Loading simulation from batch_mzm_solver/mo-ac3c5c1a-e3e6-46bf-b74e-6940137e9053.hdf5

15:26:44 EST Loading simulation from batch_mzm_solver/mo-c40f8617-f591-41e5-b192-0d2561107293.hdf5

Loading simulation from batch_mzm_solver/mo-21e26c87-140b-4059-ac68-e8ae2dd4d9ef.hdf5

Loading simulation from batch_mzm_solver/mo-59453766-d582-4246-b93f-c5b2ce270a0a.hdf5

Loading simulation from batch_mzm_solver/mo-b804fa2c-cb99-457c-93f0-f5eea92d237f.hdf5

15:26:45 EST Loading simulation from batch_mzm_solver/mo-71dd4a1e-4c49-4ea3-bb9f-fc8779e5d6e8.hdf5

Loading simulation from batch_mzm_solver/mo-0699e765-c4e4-4c7e-8eca-6b6d8aed0e8b.hdf5

Loading simulation from batch_mzm_solver/mo-d99fb402-ae39-446a-97f5-7b1b5a8166d7.hdf5

15:26:46 EST Loading simulation from batch_mzm_solver/mo-ffe7a155-32ea-4e69-9e88-9ae673f8ba2d.hdf5

Loading simulation from batch_mzm_solver/mo-f4ee6f02-3d1f-430d-8bc7-e1051c545a55.hdf5

Loading simulation from batch_mzm_solver/mo-def9d049-fcf9-44dc-9b4c-b407283cdf4d.hdf5

15:26:47 EST Loading simulation from batch_mzm_solver/mo-31007ea9-b385-45b3-8161-a1f295635d9f.hdf5

Loading simulation from batch_mzm_solver/mo-3c042c10-3bda-4922-9ef2-0bc322a4dd38.hdf5

Loading simulation from batch_mzm_solver/mo-0a081e3a-dc62-41cb-bd69-5e5d99da6d86.hdf5

15:26:48 EST Loading simulation from batch_mzm_solver/mo-b2f11724-75b7-425e-bb37-d871f12d43b5.hdf5

Loading simulation from batch_mzm_solver/mo-4f4afc5b-1bfe-4667-ade0-a8e70d700b92.hdf5

Loading simulation from batch_mzm_solver/mo-48f72b04-208d-46dd-9e24-cd7175df44ad.hdf5

15:26:49 EST Loading simulation from batch_mzm_solver/mo-aa0a7482-e6f2-4af8-a36c-67a44cf155e4.hdf5

Loading simulation from batch_mzm_solver/mo-8d27c2a9-f134-4ae0-bc6d-30e4860fa56d.hdf5

Loading simulation from batch_mzm_solver/mo-afca8637-ff67-40f2-a151-59788572d929.hdf5

15:26:50 EST Loading simulation from batch_mzm_solver/mo-fd7e77fb-b84a-4142-b3fb-0a2059ad8b8d.hdf5

Loading simulation from batch_mzm_solver/mo-b6c78a1f-de91-41c5-988a-45658bd4dac1.hdf5

Loading simulation from batch_mzm_solver/mo-30aedb9c-9017-4604-a9a7-997003c89493.hdf5

15:26:51 EST Loading simulation from batch_mzm_solver/mo-f4d97453-0578-4875-b791-d1d79b287e6a.hdf5

Loading simulation from batch_mzm_solver/mo-b2fc54b5-a46f-4646-b517-1fad7ce72fbd.hdf5

Loading simulation from batch_mzm_solver/mo-8fd28f77-b107-40ea-b109-c51e4c61b83a.hdf5

15:26:52 EST Loading simulation from batch_mzm_solver/mo-ee7ee06d-57e0-42e7-bb07-ddcfbdeb133f.hdf5

Loading simulation from batch_mzm_solver/mo-ebdf7422-77c2-4be5-9b33-8a7bfc93333d.hdf5

Loading simulation from batch_mzm_solver/mo-a78e9087-95d0-4960-8294-ff865240741b.hdf5

Loading simulation from batch_mzm_solver/mo-fcaf20af-ae7f-4bb2-8125-a29861531c83.hdf5

15:26:53 EST Loading simulation from batch_mzm_solver/mo-2e549ceb-5b38-459f-a981-a10b34782eb6.hdf5

Loading simulation from batch_mzm_solver/mo-f233c4e5-b477-4e59-8228-7e52aa469e1d.hdf5

Loading simulation from batch_mzm_solver/mo-db198603-049b-4e88-b558-075b629d1f7f.hdf5

15:26:54 EST Loading simulation from batch_mzm_solver/mo-b27a97e9-4c46-4410-a65e-7ba1d97c264e.hdf5

Loading simulation from batch_mzm_solver/mo-b625fb5e-8436-4b04-a4e1-9006288812e6.hdf5

Loading simulation from batch_mzm_solver/mo-e74cd13f-6531-4396-b45f-34ecc4923793.hdf5

15:26:55 EST Loading simulation from batch_mzm_solver/mo-822dd4cd-0335-4111-932f-00628159b388.hdf5

Loading simulation from batch_mzm_solver/mo-dc20e093-74e5-437c-ad92-7bbf200a17cd.hdf5

Loading simulation from batch_mzm_solver/mo-cd2867e8-4600-4466-99a6-204e367d451a.hdf5

15:26:56 EST Loading simulation from batch_mzm_solver/mo-fd9a20c5-ce4d-490e-ac24-7f90d321e018.hdf5

Loading simulation from batch_mzm_solver/mo-3ea1bc34-8bea-4ba5-8a65-56c141dbb37f.hdf5

Loading simulation from batch_mzm_solver/mo-1ffe632c-6174-4229-86c1-a5ad347fb6ff.hdf5

15:26:57 EST Loading simulation from batch_mzm_solver/mo-95188a9f-ac1d-4fad-a088-22a6c715c077.hdf5

Loading simulation from batch_mzm_solver/mo-455c215e-8d90-415b-a3c6-fab52a93835e.hdf5

Loading simulation from batch_mzm_solver/mo-9917f672-9c42-4650-b621-2aefd98f04bf.hdf5

15:26:58 EST Loading simulation from batch_mzm_solver/mo-e0e1ecc8-59f6-49ed-b4cc-783eceb6a474.hdf5

Loading simulation from batch_mzm_solver/mo-5d0e4665-7d7c-4cfa-93cd-0a7246349c4e.hdf5

Loading simulation from batch_mzm_solver/mo-5b8f59bd-aa2c-4d07-a3d7-924af158e236.hdf5

15:26:59 EST Loading simulation from batch_mzm_solver/mo-f33b4862-ff5f-4d81-9c45-09a5d679395c.hdf5

Loading simulation from batch_mzm_solver/mo-8b7885bf-71d7-4f4e-bdbd-7ec139a0b2f7.hdf5

Loading simulation from batch_mzm_solver/mo-ff06af82-b127-4c22-aac1-50f90868f877.hdf5

15:27:00 EST Loading simulation from batch_mzm_solver/mo-7e258be4-67bd-41b3-b567-34a24400da29.hdf5

Loading simulation from batch_mzm_solver/mo-4fdac554-29cd-4df2-b3b9-f55206ce3ec2.hdf5

Loading simulation from batch_mzm_solver/mo-bfabdf62-3b4a-45dc-8099-65ce5c9863c9.hdf5

15:27:01 EST Loading simulation from batch_mzm_solver/mo-25999a12-cd8f-4aed-9377-8e43460bdc94.hdf5

Loading simulation from batch_mzm_solver/mo-834dea6b-559e-41b9-a387-d5fbcf689a3b.hdf5

Loading simulation from batch_mzm_solver/mo-202c2f7f-3c46-49a3-a0fb-9f03a0898c43.hdf5

15:27:02 EST Loading simulation from batch_mzm_solver/mo-843a1875-6f01-4796-9eef-cf63658691fe.hdf5

Loading simulation from batch_mzm_solver/mo-0df16476-468f-41ef-afca-bf3c7440d9dd.hdf5

Loading simulation from batch_mzm_solver/mo-1429bbb2-8a12-4a78-803f-5db7d325d157.hdf5

15:27:03 EST Loading simulation from batch_mzm_solver/mo-053f8c71-6279-4df8-927e-8787d7e7eb27.hdf5

Loading simulation from batch_mzm_solver/mo-4943e66c-9d75-4cde-97ed-1685cfbfe4c3.hdf5

Loading simulation from batch_mzm_solver/mo-b602a693-414d-4354-a6b9-65172b18f6bf.hdf5

15:27:04 EST Loading simulation from batch_mzm_solver/mo-0a1d8ea4-0571-43a6-a8db-bb39ddfe5078.hdf5

Loading simulation from batch_mzm_solver/mo-c57a9f72-d149-4ffa-8405-8d0ab25dbbd0.hdf5

Loading simulation from batch_mzm_solver/mo-02de1f3c-6d10-41e0-8ad4-c20e1333032b.hdf5

15:27:05 EST Loading simulation from batch_mzm_solver/mo-4c310f44-3213-446a-95a3-09637f7ec7be.hdf5

Loading simulation from batch_mzm_solver/mo-15fc7daf-54f0-4ae3-b102-610e32a68af3.hdf5

Loading simulation from batch_mzm_solver/mo-931cda8e-c338-4489-bab4-745235137d2f.hdf5

15:27:06 EST Loading simulation from batch_mzm_solver/mo-d639c8f3-0929-4a33-879e-acfeed51b787.hdf5

Loading simulation from batch_mzm_solver/mo-1c90cb08-4277-449c-aff8-e74f836508c3.hdf5

Loading simulation from batch_mzm_solver/mo-6a06afda-3f9e-49ce-9fe8-8af590780635.hdf5

15:27:07 EST Loading simulation from batch_mzm_solver/mo-54cc5425-fe49-40ad-8e43-f23d0c6363c7.hdf5

Loading simulation from batch_mzm_solver/mo-d157dbde-9992-4532-afb1-741e46579bd2.hdf5

15:27:08 EST Loading simulation from batch_mzm_solver/mo-9fb7ca96-77ac-45c0-8a37-4ccf58d25a77.hdf5

Loading simulation from batch_mzm_solver/mo-b5ab2bc4-2ad6-4be0-a0fe-3c61dbb7983d.hdf5

Loading simulation from batch_mzm_solver/mo-597eb049-5df8-4894-8cb4-ac842982f50c.hdf5

15:27:09 EST Loading simulation from batch_mzm_solver/mo-805c7314-7b1c-45ad-844a-b102c566b8e2.hdf5

Loading simulation from batch_mzm_solver/mo-af3e69ef-b4ab-43f0-b13a-ee65ee9bd26e.hdf5

Loading simulation from batch_mzm_solver/mo-68eb1d29-0628-48b7-ae43-89ddbcad841f.hdf5

15:27:10 EST Loading simulation from batch_mzm_solver/mo-0888a856-774f-477d-8c1e-b8fb8a30dbee.hdf5

Loading simulation from batch_mzm_solver/mo-b2ffc4ef-bc9f-45c5-979e-804ac8335435.hdf5

import pandas as pd

df_z0 = pd.DataFrame()

df_z0.index.name = "h1"

df_z0.columns.name = "cpw_thickness"

df_neff = pd.DataFrame()

df_neff.index.name = "h1"

df_neff.columns.name = "cpw_thickness"

df_k_eff = pd.DataFrame()

df_k_eff.index.name = "h1"

df_k_eff.columns.name = "cpw_thickness"

for task_name, sim_data in batch_data.items():

I_int, V_int = dic_integrals[task_name]

Z0_mzm, n_eff, k_eff = get_impedance(sim_data, I_int, V_int, plot=False)

h1, cpw_thickness = eval(task_name)

df_z0.loc[h1, cpw_thickness] = Z0_mzm.sel(f=70e9, method="nearest").values

df_neff.loc[h1, cpw_thickness] = n_eff.sel(f=70e9, method="nearest").values

df_k_eff.loc[h1, cpw_thickness] = k_eff.sel(f=70e9, method="nearest").values

15:27:11 EST Loading simulation from batch_mzm_solver/mo-5f3a4c62-5f3b-49b3-83f4-c11b4cb70745.hdf5

Loading simulation from batch_mzm_solver/mo-8996fb52-6fd5-4659-b827-f088f79b0efb.hdf5

Loading simulation from batch_mzm_solver/mo-b1113f7e-2938-4d06-89ec-f220e86dcf0d.hdf5

Loading simulation from batch_mzm_solver/mo-1959b6a0-a5ec-4045-a1c9-786204b7d4ae.hdf5

15:27:12 EST Loading simulation from batch_mzm_solver/mo-31ac7023-db69-4cce-b4df-fc0675a8a443.hdf5

Loading simulation from batch_mzm_solver/mo-7d02415a-150e-4fe5-a416-a00afd01c0c4.hdf5

Loading simulation from batch_mzm_solver/mo-337b5a46-fb06-48d2-ab14-2ae55863b366.hdf5

15:27:13 EST Loading simulation from batch_mzm_solver/mo-245709a0-9a56-4253-a6e6-34e4f7976803.hdf5

Loading simulation from batch_mzm_solver/mo-c3f94b71-a878-49bc-a700-14bb85d723ef.hdf5

Loading simulation from batch_mzm_solver/mo-9075119b-a1bb-459a-bfab-706b6d41baed.hdf5

15:27:14 EST Loading simulation from batch_mzm_solver/mo-f2355ffe-288d-4ccf-9247-cbab9f04ebbd.hdf5

Loading simulation from batch_mzm_solver/mo-32620ef9-4d0e-4277-8c68-12f65c1838a9.hdf5

Loading simulation from batch_mzm_solver/mo-305b6a77-75cf-44b9-b3d3-8e77588db942.hdf5

15:27:15 EST Loading simulation from batch_mzm_solver/mo-d10ad170-4603-4dc1-8339-a15ac9d01dd6.hdf5

Loading simulation from batch_mzm_solver/mo-e8632d12-e314-426d-afd7-0d76836c92d4.hdf5

Loading simulation from batch_mzm_solver/mo-f38f0f2c-4725-4901-ac0b-a1483493c321.hdf5

15:27:16 EST Loading simulation from batch_mzm_solver/mo-d9b80b71-a105-42f1-8055-cbd331dbebeb.hdf5

Loading simulation from batch_mzm_solver/mo-dd59db5a-a7f3-4411-8f63-dabe5e2aa012.hdf5

Loading simulation from batch_mzm_solver/mo-ac3c5c1a-e3e6-46bf-b74e-6940137e9053.hdf5

15:27:17 EST Loading simulation from batch_mzm_solver/mo-c40f8617-f591-41e5-b192-0d2561107293.hdf5

Loading simulation from batch_mzm_solver/mo-21e26c87-140b-4059-ac68-e8ae2dd4d9ef.hdf5

Loading simulation from batch_mzm_solver/mo-59453766-d582-4246-b93f-c5b2ce270a0a.hdf5

15:27:18 EST Loading simulation from batch_mzm_solver/mo-b804fa2c-cb99-457c-93f0-f5eea92d237f.hdf5

Loading simulation from batch_mzm_solver/mo-71dd4a1e-4c49-4ea3-bb9f-fc8779e5d6e8.hdf5

Loading simulation from batch_mzm_solver/mo-0699e765-c4e4-4c7e-8eca-6b6d8aed0e8b.hdf5

15:27:19 EST Loading simulation from batch_mzm_solver/mo-d99fb402-ae39-446a-97f5-7b1b5a8166d7.hdf5

Loading simulation from batch_mzm_solver/mo-ffe7a155-32ea-4e69-9e88-9ae673f8ba2d.hdf5

Loading simulation from batch_mzm_solver/mo-f4ee6f02-3d1f-430d-8bc7-e1051c545a55.hdf5

15:27:20 EST Loading simulation from batch_mzm_solver/mo-def9d049-fcf9-44dc-9b4c-b407283cdf4d.hdf5

Loading simulation from batch_mzm_solver/mo-31007ea9-b385-45b3-8161-a1f295635d9f.hdf5

Loading simulation from batch_mzm_solver/mo-3c042c10-3bda-4922-9ef2-0bc322a4dd38.hdf5

15:27:21 EST Loading simulation from batch_mzm_solver/mo-0a081e3a-dc62-41cb-bd69-5e5d99da6d86.hdf5

Loading simulation from batch_mzm_solver/mo-b2f11724-75b7-425e-bb37-d871f12d43b5.hdf5

Loading simulation from batch_mzm_solver/mo-4f4afc5b-1bfe-4667-ade0-a8e70d700b92.hdf5

15:27:22 EST Loading simulation from batch_mzm_solver/mo-48f72b04-208d-46dd-9e24-cd7175df44ad.hdf5

Loading simulation from batch_mzm_solver/mo-aa0a7482-e6f2-4af8-a36c-67a44cf155e4.hdf5

Loading simulation from batch_mzm_solver/mo-8d27c2a9-f134-4ae0-bc6d-30e4860fa56d.hdf5

15:27:23 EST Loading simulation from batch_mzm_solver/mo-afca8637-ff67-40f2-a151-59788572d929.hdf5

Loading simulation from batch_mzm_solver/mo-fd7e77fb-b84a-4142-b3fb-0a2059ad8b8d.hdf5

Loading simulation from batch_mzm_solver/mo-b6c78a1f-de91-41c5-988a-45658bd4dac1.hdf5

15:27:24 EST Loading simulation from batch_mzm_solver/mo-30aedb9c-9017-4604-a9a7-997003c89493.hdf5

Loading simulation from batch_mzm_solver/mo-f4d97453-0578-4875-b791-d1d79b287e6a.hdf5

Loading simulation from batch_mzm_solver/mo-b2fc54b5-a46f-4646-b517-1fad7ce72fbd.hdf5

15:27:25 EST Loading simulation from batch_mzm_solver/mo-8fd28f77-b107-40ea-b109-c51e4c61b83a.hdf5

Loading simulation from batch_mzm_solver/mo-ee7ee06d-57e0-42e7-bb07-ddcfbdeb133f.hdf5

Loading simulation from batch_mzm_solver/mo-ebdf7422-77c2-4be5-9b33-8a7bfc93333d.hdf5

15:27:26 EST Loading simulation from batch_mzm_solver/mo-a78e9087-95d0-4960-8294-ff865240741b.hdf5

Loading simulation from batch_mzm_solver/mo-fcaf20af-ae7f-4bb2-8125-a29861531c83.hdf5

Loading simulation from batch_mzm_solver/mo-2e549ceb-5b38-459f-a981-a10b34782eb6.hdf5

15:27:27 EST Loading simulation from batch_mzm_solver/mo-f233c4e5-b477-4e59-8228-7e52aa469e1d.hdf5

Loading simulation from batch_mzm_solver/mo-db198603-049b-4e88-b558-075b629d1f7f.hdf5

Loading simulation from batch_mzm_solver/mo-b27a97e9-4c46-4410-a65e-7ba1d97c264e.hdf5

15:27:28 EST Loading simulation from batch_mzm_solver/mo-b625fb5e-8436-4b04-a4e1-9006288812e6.hdf5

Loading simulation from batch_mzm_solver/mo-e74cd13f-6531-4396-b45f-34ecc4923793.hdf5

15:27:29 EST Loading simulation from batch_mzm_solver/mo-822dd4cd-0335-4111-932f-00628159b388.hdf5

Loading simulation from batch_mzm_solver/mo-dc20e093-74e5-437c-ad92-7bbf200a17cd.hdf5

Loading simulation from batch_mzm_solver/mo-cd2867e8-4600-4466-99a6-204e367d451a.hdf5

15:27:30 EST Loading simulation from batch_mzm_solver/mo-fd9a20c5-ce4d-490e-ac24-7f90d321e018.hdf5

Loading simulation from batch_mzm_solver/mo-3ea1bc34-8bea-4ba5-8a65-56c141dbb37f.hdf5

Loading simulation from batch_mzm_solver/mo-1ffe632c-6174-4229-86c1-a5ad347fb6ff.hdf5

15:27:31 EST Loading simulation from batch_mzm_solver/mo-95188a9f-ac1d-4fad-a088-22a6c715c077.hdf5

Loading simulation from batch_mzm_solver/mo-455c215e-8d90-415b-a3c6-fab52a93835e.hdf5

Loading simulation from batch_mzm_solver/mo-9917f672-9c42-4650-b621-2aefd98f04bf.hdf5

15:27:32 EST Loading simulation from batch_mzm_solver/mo-e0e1ecc8-59f6-49ed-b4cc-783eceb6a474.hdf5

Loading simulation from batch_mzm_solver/mo-5d0e4665-7d7c-4cfa-93cd-0a7246349c4e.hdf5

15:27:33 EST Loading simulation from batch_mzm_solver/mo-5b8f59bd-aa2c-4d07-a3d7-924af158e236.hdf5

Loading simulation from batch_mzm_solver/mo-f33b4862-ff5f-4d81-9c45-09a5d679395c.hdf5

Loading simulation from batch_mzm_solver/mo-8b7885bf-71d7-4f4e-bdbd-7ec139a0b2f7.hdf5

15:27:34 EST Loading simulation from batch_mzm_solver/mo-ff06af82-b127-4c22-aac1-50f90868f877.hdf5

Loading simulation from batch_mzm_solver/mo-7e258be4-67bd-41b3-b567-34a24400da29.hdf5

Loading simulation from batch_mzm_solver/mo-4fdac554-29cd-4df2-b3b9-f55206ce3ec2.hdf5

15:27:35 EST Loading simulation from batch_mzm_solver/mo-bfabdf62-3b4a-45dc-8099-65ce5c9863c9.hdf5

Loading simulation from batch_mzm_solver/mo-25999a12-cd8f-4aed-9377-8e43460bdc94.hdf5

Loading simulation from batch_mzm_solver/mo-834dea6b-559e-41b9-a387-d5fbcf689a3b.hdf5

15:27:36 EST Loading simulation from batch_mzm_solver/mo-202c2f7f-3c46-49a3-a0fb-9f03a0898c43.hdf5

Loading simulation from batch_mzm_solver/mo-843a1875-6f01-4796-9eef-cf63658691fe.hdf5

Loading simulation from batch_mzm_solver/mo-0df16476-468f-41ef-afca-bf3c7440d9dd.hdf5

15:27:37 EST Loading simulation from batch_mzm_solver/mo-1429bbb2-8a12-4a78-803f-5db7d325d157.hdf5

Loading simulation from batch_mzm_solver/mo-053f8c71-6279-4df8-927e-8787d7e7eb27.hdf5

15:27:38 EST Loading simulation from batch_mzm_solver/mo-4943e66c-9d75-4cde-97ed-1685cfbfe4c3.hdf5

Loading simulation from batch_mzm_solver/mo-b602a693-414d-4354-a6b9-65172b18f6bf.hdf5

Loading simulation from batch_mzm_solver/mo-0a1d8ea4-0571-43a6-a8db-bb39ddfe5078.hdf5

15:27:39 EST Loading simulation from batch_mzm_solver/mo-c57a9f72-d149-4ffa-8405-8d0ab25dbbd0.hdf5

Loading simulation from batch_mzm_solver/mo-02de1f3c-6d10-41e0-8ad4-c20e1333032b.hdf5

15:27:40 EST Loading simulation from batch_mzm_solver/mo-4c310f44-3213-446a-95a3-09637f7ec7be.hdf5

Loading simulation from batch_mzm_solver/mo-15fc7daf-54f0-4ae3-b102-610e32a68af3.hdf5

Loading simulation from batch_mzm_solver/mo-931cda8e-c338-4489-bab4-745235137d2f.hdf5

15:27:41 EST Loading simulation from batch_mzm_solver/mo-d639c8f3-0929-4a33-879e-acfeed51b787.hdf5

Loading simulation from batch_mzm_solver/mo-1c90cb08-4277-449c-aff8-e74f836508c3.hdf5

Loading simulation from batch_mzm_solver/mo-6a06afda-3f9e-49ce-9fe8-8af590780635.hdf5

15:27:42 EST Loading simulation from batch_mzm_solver/mo-54cc5425-fe49-40ad-8e43-f23d0c6363c7.hdf5

Loading simulation from batch_mzm_solver/mo-d157dbde-9992-4532-afb1-741e46579bd2.hdf5

Loading simulation from batch_mzm_solver/mo-9fb7ca96-77ac-45c0-8a37-4ccf58d25a77.hdf5

15:27:43 EST Loading simulation from batch_mzm_solver/mo-b5ab2bc4-2ad6-4be0-a0fe-3c61dbb7983d.hdf5

Loading simulation from batch_mzm_solver/mo-597eb049-5df8-4894-8cb4-ac842982f50c.hdf5

15:27:44 EST Loading simulation from batch_mzm_solver/mo-805c7314-7b1c-45ad-844a-b102c566b8e2.hdf5

Loading simulation from batch_mzm_solver/mo-af3e69ef-b4ab-43f0-b13a-ee65ee9bd26e.hdf5

Loading simulation from batch_mzm_solver/mo-68eb1d29-0628-48b7-ae43-89ddbcad841f.hdf5

15:27:45 EST Loading simulation from batch_mzm_solver/mo-0888a856-774f-477d-8c1e-b8fb8a30dbee.hdf5

Loading simulation from batch_mzm_solver/mo-b2ffc4ef-bc9f-45c5-979e-804ac8335435.hdf5

fig, Ax = plt.subplots(ncols=3, figsize=(17, 5))

pm1 = Ax[0].pcolormesh(

df_z0.index, df_z0.columns, df_z0.values.T.real, cmap="jet", shading="gouraud"

)

cb1 = plt.colorbar(pm1)

cb1.set_label("Impedance (Ω)")

pm2 = Ax[1].pcolormesh(

df_neff.index, df_neff.columns, df_neff.values.T, cmap="jet", shading="gouraud"

)

cb2 = plt.colorbar(pm2)

cb2.set_label("Effective Index")

df_alpha = 2 * np.pi * (70e9 / td.C_0) * df_k_eff * 10**6

pm3 = Ax[2].pcolormesh(

df_alpha.index, df_alpha.columns, df_alpha.values.T, cmap="jet", shading="gouraud"

)

cb3 = plt.colorbar(pm3)

cb3.set_label("Attenuation Constant $\\alpha$ (1/m)")

for ax in Ax:

ax.set_ylim(Ax[2].get_ylim()[::-1])

ax.set_xlabel("h1 (µm)")

plt.show()

cpw_width = 18

cpw_gap = 5

cpw_thickness = 1

h1 = 0.5

optical_waveguide_gap = 25

sim_final, mzm_solver_final, I_int_final, V_int_final = get_sim(

h4=4.7, # top SiO2 cladding thickness (µm)

h2=0.4,

h1=h1, # lower layer thickness beneath the electrodes (µm)

cpw_thickness=cpw_thickness, # CPW geometry parameters (t)

cpw_width=cpw_width, # w1

cpw_gap=cpw_gap,

optical_waveguide_gap=optical_waveguide_gap,

refinement=20,

resolution=60,

) # g

mzm_solver_final_data = web.run(

mzm_solver_final, task_name="MZM mode solver", path="data/MZM_mode_data.hdf5"

)

15:27:46 EST Created task 'MZM mode solver' with resource_id 'mo-ef231e09-d7d9-485c-a560-7af64b5b12bb' and task_type 'MODE_SOLVER'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-ef231e09-d7d9- 485c-a560-7af64b5b12bb'.

Task folder: 'default'.

Output()

15:27:56 EST Estimated FlexCredit cost: 0.009. Minimum cost depends on task execution details. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

15:30:20 EST starting up solver

running solver

15:30:38 EST status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=mo-ef231e09-d7d9- 485c-a560-7af64b5b12bb'.

Output()

15:30:43 EST Loading simulation from data/MZM_mode_data.hdf5

To calculate the Pockels effect, we apply an electric field along the LiNbO₃ cut direction to perturb the optical medium. First, we normalize the field by the applied voltage on the push-pull configuration.

# Compute voltage across the gap and normalize electric field

v0 = V_int_final.compute_voltage(mzm_solver_final_data)

ey_norm = (mzm_solver_final_data.Ey / (0.5 * v0.real)).isel(f=0, mode_index=0, drop=True).abs

waveguide_center = sim_final.structures[8].geometry.bounding_box.center

ax = ey_norm.isel(x=0).transpose("z", "y").plot(robust=True).axes

ax.set_xlim(waveguide_center[1] - 2, waveguide_center[1] + 2)

ax.set_ylim(waveguide_center[2] - 1.5, waveguide_center[2] + 1.5)

ax.set_aspect("equal")

plt.show()

The normalized electric field is applied to the LiNbO₃ crystal along its z-axis, following the Pockels effect model:

$$ \Delta_n = -0.5 n_e^3 r_{33} E $$

Where:

- $\Delta_n$: Index variation

- $n_e$: Extraordinary refractive index

- $r_{33}$: Pockels coefficient (30.9 pm/V)

- $E$: Normalized electric field from CPW (1V across gap)

# Extract LiNbO3 material properties at optical wavelength

eps_o, eps_e, _ = (e.real for e in LiNbO3.eps_diagonal(td.C_0 / opt_wavelength))

n_e = eps_e**0.5

r33 = 30.9e-6 # Pockels coefficient in μm/V

# Calculate refractive index variation from Pockels effect

Δn = -0.5 * n_e**3 * r33 * ey_norm

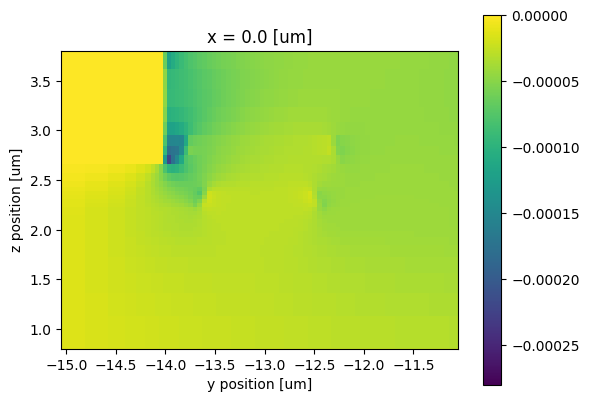

# Plot index variation (perturbation will only take effect over the LiNbO₃ regions)

ax = Δn.isel(x=0).transpose("z", "y").plot(robust=False).axes

ax.set_xlim(waveguide_center[1] - 2, waveguide_center[1] + 2)

ax.set_ylim(waveguide_center[2] - 1.5, waveguide_center[2] + 1.5)

ax.set_aspect("equal")

plt.show()

Now, assuming that the field scales with the applied voltage, we can define an auxiliary function to create the perturbed medium using a CustomAnisotropicMedium object as a function of the voltage.

This incorporates the index change due to the RF fields and returns a ModeSolver object.

# Use a single data point for the homogeneous directions

eps_o_array = td.SpatialDataArray(np.full((1, 1, 1), eps_o), coords={"x": [0], "y": [0], "z": [0]})

def perturbed_solver(voltage):

perturbed_ln = td.CustomAnisotropicMedium(

xx=td.CustomMedium(permittivity=eps_o_array, subpixel=True),

yy=td.CustomMedium(permittivity=(n_e + voltage * Δn) ** 2, subpixel=True),

zz=td.CustomMedium(permittivity=eps_o_array, subpixel=True),

)

# Changing the RF mediums to optical mediums

si02_structures_index = [0, 9, 12]

ln_structures_index = [7, 8, 10, 11]

perturbed_structures = list(sim_final.structures)

for i in si02_structures_index:

perturbed_structures[i] = sim_final.structures[i].updated_copy(medium=SiO2)

for i in ln_structures_index:

perturbed_structures[i] = sim_final.structures[i].updated_copy(medium=perturbed_ln)

# Remove metals

del perturbed_structures[2:5]

center = waveguide_center

size = (0, 8, 3)

perturbed_sim = sim_final.updated_copy(

structures=perturbed_structures, size=size, center=center, grid_spec=sim_opt.grid_spec

)

ms = mode_solver_opt.updated_copy(

simulation=perturbed_sim, plane=td.Box(size=size, center=center)

)

return ms

Next, we create a Batch and run all mode simulations in parallel.

# Define voltages to apply and create a Batch of simulations

voltages = np.arange(5)

sims = {str(v): perturbed_solver(v) for v in voltages}

batch = web.Batch(simulations=sims, folder_name="perturbed_mode")

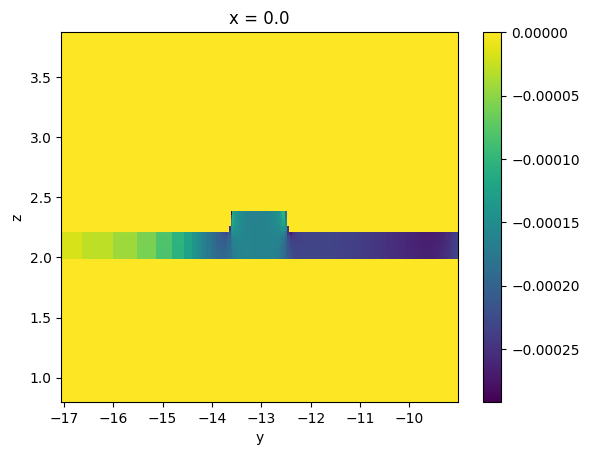

We can now visualize the index change for 4V bias.

eps0 = sims["0"].simulation.epsilon(sims["0"].plane)

eps4 = sims["4"].simulation.epsilon(sims["4"].plane)

delta_eps = eps4 - eps0

delta_eps.T.real.plot()

plt.show()

Output()

Output()

# Run all simulations in parallel

batch_data = batch.run(path_dir="batch_perturbed_mode")

Output()

15:31:04 EST Started working on Batch containing 5 tasks.

15:31:42 EST Maximum FlexCredit cost: 0.023 for the whole batch.

Use 'Batch.real_cost()' to get the billed FlexCredit cost after completion.

Output()

15:32:03 EST Batch complete.

15:32:04 EST Loading simulation from batch_perturbed_mode/mo-512d5306-c0c5-4968-acbd-8d346b2ad238.hdf5

Loading simulation from batch_perturbed_mode/mo-3530ad8b-d91a-431d-84a7-53fc67020c9e.hdf5

15:32:05 EST Loading simulation from batch_perturbed_mode/mo-e85a38cd-6646-433d-95c2-6f91c98a6362.hdf5

Loading simulation from batch_perturbed_mode/mo-b0b3be74-39a8-4009-ba71-ebb5e081a822.hdf5

Loading simulation from batch_perturbed_mode/mo-3f6d5773-368d-4f81-b572-b6d8c6a0482c.hdf5

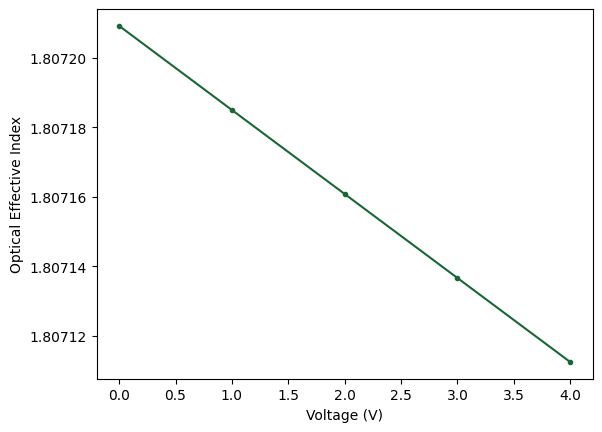

Finally, we can observe the variation of the waveguide mode effective index as a function of the applied voltage and calculate the Vπ·L figure of merit.

n_eff = [sim_data.n_eff.isel(mode_index=0, f=0).item() for sim_data in batch_data.values()]

_ = plt.plot(voltages, n_eff, ".-")

_ = plt.ticklabel_format(style="plain", useOffset=False)

plt.gca().set(xlabel="Voltage (V)", ylabel="Optical Effective Index")

plt.show()

15:32:06 EST Loading simulation from batch_perturbed_mode/mo-512d5306-c0c5-4968-acbd-8d346b2ad238.hdf5

Loading simulation from batch_perturbed_mode/mo-3530ad8b-d91a-431d-84a7-53fc67020c9e.hdf5

Loading simulation from batch_perturbed_mode/mo-e85a38cd-6646-433d-95c2-6f91c98a6362.hdf5

15:32:07 EST Loading simulation from batch_perturbed_mode/mo-b0b3be74-39a8-4009-ba71-ebb5e081a822.hdf5

Loading simulation from batch_perturbed_mode/mo-3f6d5773-368d-4f81-b572-b6d8c6a0482c.hdf5

# The variation is quite linear, so we simply use the largest interval

dneff_dV = abs(n_eff[-1] - n_eff[0]) / (voltages[-1] - voltages[0])

vpil = 0.5 * opt_wavelength / dneff_dV # in V·μm"

print(f"Vπ·L (push-pull) = {vpil * 1e-4 / 2:.2f} V·cm")

Vπ·L (push-pull) = 1.61 V·cm