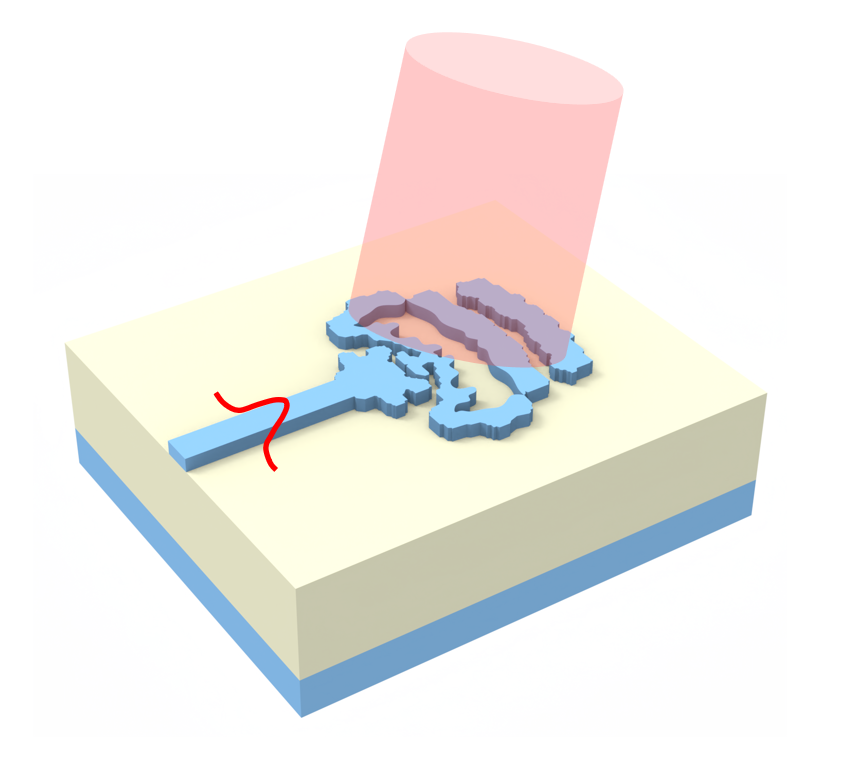

Fiber lenses, or microlenses fabricated directly on optical fiber tips, are essential components for beam shaping, focusing, and coupling in fiber-optic systems. Applications range from optical trapping and sensing to endoscopy and telecommunications.

In this notebook, we design a fiber lens by optimizing the 3D surface profile of a cylindrically symmetric structure attached to the tip of a single-mode fiber. The lens surface is parameterized as concentric rings whose heights are adjusted via gradient-based inverse design using Tidy3D's native autograd support. The objective is to maximize the optical flux transmitted to a small focal region in front of the fiber.

We demonstrate free-form 3D shape optimization using a fully differentiable TriangleMesh geometry. Unlike topology optimization on a fixed pixel grid, this approach directly optimizes vertex positions of a surface mesh, enabling smooth, fabrication-ready freeform surfaces that can be exported directly to STL. This capability is particularly powerful for freeform optics where the optimal shape cannot be described by simple geometric primitives.

Initial Setup¶

We begin by importing the necessary packages and defining the key parameters for our simulation. The physical setup consists of:

- Fiber base: A single-mode fiber with core and cladding

- Lens structure: A cylinder-like design region whose top surface will be optimized

- Exit monitor: A small field monitor at the target focal plane to measure focusing efficiency

The lens surface is discretized into num_rings concentric rings, each with an adjustable height. A Gaussian smoothing kernel is applied to ensure smooth, fabricable transitions between adjacent rings.

import autograd.numpy as anp

import matplotlib.pyplot as plt

import numpy as np

import optax

import tidy3d as td

import tidy3d.web as web

from autograd import value_and_grad

from autograd.scipy.signal import convolve

from tidy3d.components.autograd import get_static

td.config.logging.level = "ERROR" # disable warning about large number of source grid points

# Operating wavelength and frequency (units: µm)

wvl = 1.55

freq0 = td.C_0 / wvl

# Fiber geometry and refractive indices (approximate SMF-28 values)

d_smf_core = 8.2 # core diameter (µm)

n_smf_core = 1.449217 # core refractive index

n_smf_clad = 1.444 # cladding refractive index

n_design = 2.0 # refractive index of lens material (e.g., polymer or glass)

base_design_radius = 10 # radius of the lens base (µm)

fiber_length = 2 # length of fiber section in simulation (µm)

# Longitudinal layout (µm)

initial_height = 2.0 # starting height for all rings

free_space_length = 20.0 # propagation distance to focal plane

pml_buffer = wvl * 1.5 # buffer between structures and PML

monitor_buffer = 0.5 # buffer for source/monitor placement

# Simulation domain extent (µm)

sim_Ly = sim_Lz = 2 * base_design_radius + pml_buffer

sim_Lx = fiber_length + free_space_length

exit_monitor_size = 0.5 # size of the focal spot monitor

# Mesh parameterization

num_rings = 128 # number of concentric rings (design parameters)

ring_segments = 128 # polygon edges per ring (angular resolution)

smooth_sigma_frac = 0.02 # smoothing kernel width = num_rings * smooth_sigma_frac

# Height bounds for optimization (µm)

min_height, max_height = 0.1, 10.0

Simulation Setup¶

We now construct the base simulation containing the optical fiber without the lens structure. The fiber consists of a cylindrical core (higher refractive index) surrounded by cladding (lower refractive index). Both extend beyond the simulation boundaries to avoid edge effects at the PML.

INF = 1000

clad = td.Structure(

geometry=td.Box.from_bounds((-INF, -INF, -INF), (fiber_length, INF, INF)),

medium=td.Medium(permittivity=n_smf_clad**2),

)

core = td.Structure(

geometry=td.Cylinder(

center=clad.geometry.center,

radius=d_smf_core / 2,

length=clad.geometry.size[0],

axis=0,

),

medium=td.Medium(permittivity=n_smf_core**2),

)

We excite the fundamental mode of the fiber using a ModeSource. The mode solver automatically finds the guided mode, and we filter for TE polarization. The source emits a Gaussian pulse centered at the operating wavelength.

mode_source = td.ModeSource(

size=(0, sim_Ly, sim_Lz),

center=(monitor_buffer, 0, 0),

source_time=td.GaussianPulse(freq0=freq0, fwidth=0.2 * freq0),

mode_spec=td.ModeSpec(

num_modes=1,

target_neff=n_smf_core,

sort_spec=td.ModeSortSpec(filter_key="TE_fraction", filter_reference=0.5),

num_pml=(12, 12),

),

direction="+",

name="fiber_input",

)

A FieldMonitor is placed at the target focal plane to capture the electric and magnetic fields. The monitor size defines the "focal spot" region where we want to concentrate light.

exit_monitor = td.FieldMonitor(

center=(sim_Lx - monitor_buffer, 0, 0),

size=(0, exit_monitor_size, exit_monitor_size),

freqs=[freq0],

name="field_exit",

)

We now assemble the base simulation with the fiber structures, source, and monitors. Optionally, a field monitor at z=0 can be added to visualize the field propagation along the optical axis.

def make_base_simulation(monitor_propagation=False):

"""Create the parameter-independent base simulation."""

monitors = [exit_monitor]

if monitor_propagation:

monitors.append(

td.FieldMonitor(

center=(0, 0, 0), size=(td.inf, td.inf, 0), freqs=[freq0], name="field_z_0"

)

)

propagation_distance = initial_height + free_space_length

run_time = 10 * propagation_distance / td.C_0

sim = td.Simulation(

size=(sim_Lx, sim_Ly, sim_Lz),

center=(sim_Lx / 2, 0, 0),

grid_spec=td.GridSpec.auto(min_steps_per_wvl=20, wavelength=wvl),

structures=[clad, core],

sources=[mode_source],

monitors=monitors,

run_time=run_time,

)

return sim

base_sim = make_base_simulation()

Let's visualize the base simulation in 2D cross-sections and 3D to verify the geometry and component placement.

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(12, 4))

base_sim.plot(x=fiber_length / 2, ax=ax1)

ax1.set_title(f"Cross-section at x = {fiber_length / 2} µm")

base_sim.plot(z=0, ax=ax2)

ax2.set_title("Top view at z = 0")

plt.show()

base_sim.plot_3d()

Mesh Construction¶

The lens geometry is defined as a TriangleMesh constructed from vertices and faces. The surface is parameterized as follows:

- Base ring: A circle at the fiber tip (height = 0) forming the lens base

- Concentric top rings: Each ring has an adjustable height controlled by the optimization parameters

- Center vertices: Top and bottom center points to close the mesh

The height profile is smoothed using a Gaussian kernel to ensure gradual transitions between adjacent rings, which improves manufacturability and avoids sharp discontinuities that could cause meshing issues.

def vertices_from_params(params):

def smooth_param_profile(params):

sigma = smooth_sigma_frac * len(params)

if sigma == 0:

return params

pad = max(1, int(4 * sigma))

# gaussian kernel

x = anp.arange(-pad, pad + 1)

k = anp.exp(-0.5 * (x / sigma) ** 2)

k /= k.sum()

# padding

left_pad = params[1 : pad + 1][::-1]

right_pad = params[-pad - 1 : -1][::-1]

padded = anp.concatenate([left_pad, params, right_pad])

# convolve

smoothed = convolve(padded, k, mode="valid")

return smoothed

heights = smooth_param_profile(params)

theta = anp.linspace(0.0, 2.0 * anp.pi, ring_segments, endpoint=False)

cos_t = anp.cos(theta)

sin_t = anp.sin(theta)

rings = []

# bottom base ring at height = 0

X = anp.full(ring_segments, fiber_length)

Y = base_design_radius * cos_t

Z = base_design_radius * sin_t

rings.append(anp.stack([X, Y, Z], axis=1))

# rings for radius > 0

ring_radii = np.linspace(0.0, base_design_radius, num_rings)

for radius, h in zip(ring_radii[1:], heights[1:]):

X = anp.full(ring_segments, fiber_length + h)

Y = radius * cos_t

Z = radius * sin_t

rings.append(anp.stack([X, Y, Z], axis=1))

vertices = anp.concatenate(rings, axis=0)

# bottom and top center vertex

top_center = anp.array([[fiber_length + heights[0], 0.0, 0.0]])

bottom_center = anp.array([[fiber_length + 0.0, 0.0, 0.0]])

vertices = anp.concatenate([vertices, top_center, bottom_center], axis=0)

return vertices

Next, we define the triangular faces that connect the vertices. The vertex ordering must be counter-clockwise when viewed from outside the mesh to ensure correct surface normals.

def build_faces(num_rings):

faces: list[list[int]] = []

def ring_offset(i: int) -> int:

return i * ring_segments

K = num_rings - 1 # index of the outermost top ring

top_center_idx = num_rings * ring_segments

bottom_center_idx = top_center_idx + 1

# ---- side wall between base ring and outermost top ring ----

base = ring_offset(0)

outer = ring_offset(K)

for j in range(ring_segments):

jn = (j + 1) % ring_segments

faces.append([base + j, base + jn, outer + j])

faces.append([base + jn, outer + jn, outer + j])

# center fan on top surface: top_center ↔ ring 1

inner_ring = ring_offset(1)

for j in range(ring_segments):

jn = (j + 1) % ring_segments

faces.append([top_center_idx, inner_ring + j, inner_ring + jn])

# ring-by-ring faces between top rings:

# connect 1↔2, 2↔3, ..., (K-1)↔K

for i in range(1, K):

r0 = ring_offset(i)

r1 = ring_offset(i + 1)

for j in range(ring_segments):

jn = (j + 1) % ring_segments

faces.append([r0 + j, r1 + j, r0 + jn])

faces.append([r0 + jn, r1 + j, r1 + jn])

# ---- bottom disk: fan from bottom_center to base ring ----

base_start = ring_offset(0)

for j in range(ring_segments):

jn = (j + 1) % ring_segments

faces.append([bottom_center_idx, base_start + jn, base_start + j])

faces = anp.array(faces, dtype=int)

return faces

We can now construct the complete mesh from a parameter vector. The mesh_from_params function computes vertices from the parameters and combines them with the precomputed face connectivity to create a TriangleMesh object.

FACE_ARRAY = build_faces(num_rings)

def mesh_from_params(params):

vertices = vertices_from_params(params)

triangles = vertices[FACE_ARRAY]

mesh = td.TriangleMesh.from_triangles(triangles)

return mesh

Mesh Visualization¶

Before optimization, let's verify the mesh construction by creating a lens with randomized ring heights. This helps confirm that the geometry, smoothing, and triangulation work correctly.

def get_fiber_design_sim(params, monitor_propagation=False):

"""Create simulation with fiber and parameterized lens structure."""

mesh = mesh_from_params(params)

base_sim = make_base_simulation(monitor_propagation=monitor_propagation)

medium = td.Medium(permittivity=n_design**2)

design_structure = td.Structure(geometry=mesh, medium=medium, name="lens")

new_structures = [*base_sim.structures, design_structure]

return base_sim.updated_copy(structures=new_structures, validate=True)

# Create example with random perturbations

example_params = np.full(num_rings, initial_height) + np.random.randn(num_rings) * 0.5

example_design_sim = get_fiber_design_sim(example_params)

example_design_sim.plot_3d() # 3D plot

example_design_sim.plot(z=0) # 2D plot

<Axes: title={'center': 'cross section at z=0.00 (μm)'}, xlabel='x (μm)', ylabel='y (μm)'>

Objective Function¶

The objective function defines what we want to optimize. Here, we maximize the optical power (flux) transmitted through the exit monitor at the focal plane. The function:

- Constructs a simulation from the current parameters

- Runs the FDTD simulation via

web.run() - Extracts and returns the flux from the field monitor

def objective(params):

"""Compute the flux at the focal plane for a given set of ring heights."""

sim = get_fiber_design_sim(params)

sim_data = web.run(sim, task_name="fiber_lens_opt", verbose=False)

flux = sim_data["field_exit"].flux.values

return flux

Optimization¶

We use optax with the Adam optimizer to iteratively improve the lens design. At each step:

- Compute the objective value and gradient using

value_and_grad - Update parameters using Adam

- Clip parameters to stay within physical bounds

The gradient is computed efficiently via the adjoint method: only two simulations (forward + adjoint) are needed per step, regardless of the 128 design parameters.

# Optimization configuration

num_steps = 30

learning_rate = 0.1

# Initialize parameters (uniform height) and optimizer

params = anp.full(num_rings, initial_height, dtype=float)

optimizer = optax.adam(learning_rate=learning_rate)

opt_state = optimizer.init(params)

val_and_grad = value_and_grad(objective)

# Optimization loop

history = []

for step in range(1, num_steps + 1):

value, grad = val_and_grad(params)

history.append(float(value.item()))

grad_norm = float(np.linalg.norm(grad))

print(f"Step {step:02d}/{num_steps}: flux = {value.item():.4e}, ||∇|| = {grad_norm:.4e}")

# Update parameters (maximize by negating gradient)

updates, opt_state = optimizer.update(-grad, opt_state, params)

params = optax.apply_updates(params, updates)

params = anp.clip(params, min_height, max_height)

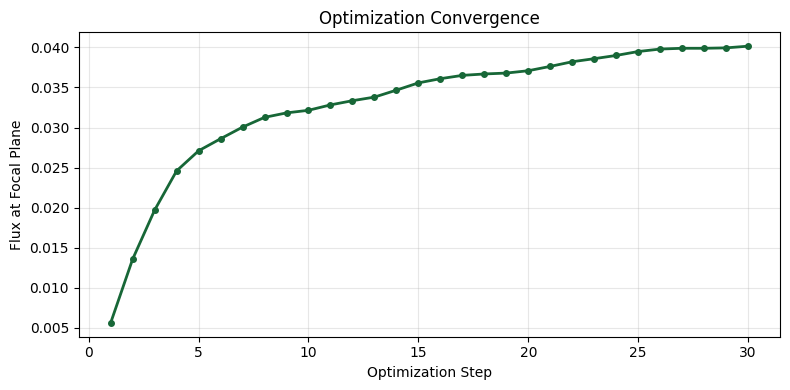

Step 01/30: flux = 5.6026e-03, ||∇|| = 8.6030e-03 Step 02/30: flux = 1.3560e-02, ||∇|| = 9.4723e-03 Step 03/30: flux = 1.9681e-02, ||∇|| = 7.9627e-03 Step 04/30: flux = 2.4583e-02, ||∇|| = 8.1960e-03 Step 05/30: flux = 2.7092e-02, ||∇|| = 1.0414e-02 Step 06/30: flux = 2.8598e-02, ||∇|| = 1.0662e-02 Step 07/30: flux = 3.0051e-02, ||∇|| = 9.9789e-03 Step 08/30: flux = 3.1268e-02, ||∇|| = 9.3117e-03 Step 09/30: flux = 3.1827e-02, ||∇|| = 9.7807e-03 Step 10/30: flux = 3.2152e-02, ||∇|| = 1.0412e-02 Step 11/30: flux = 3.2826e-02, ||∇|| = 9.1949e-03 Step 12/30: flux = 3.3350e-02, ||∇|| = 7.6230e-03 Step 13/30: flux = 3.3799e-02, ||∇|| = 8.1709e-03 Step 14/30: flux = 3.4668e-02, ||∇|| = 7.4223e-03 Step 15/30: flux = 3.5575e-02, ||∇|| = 6.2110e-03 Step 16/30: flux = 3.6098e-02, ||∇|| = 5.7248e-03 Step 17/30: flux = 3.6513e-02, ||∇|| = 5.0135e-03 Step 18/30: flux = 3.6688e-02, ||∇|| = 4.8511e-03 Step 19/30: flux = 3.6800e-02, ||∇|| = 5.5917e-03 Step 20/30: flux = 3.7094e-02, ||∇|| = 6.0787e-03 Step 21/30: flux = 3.7635e-02, ||∇|| = 5.4121e-03 Step 22/30: flux = 3.8216e-02, ||∇|| = 4.8297e-03 Step 23/30: flux = 3.8598e-02, ||∇|| = 5.1152e-03 Step 24/30: flux = 3.9002e-02, ||∇|| = 5.0577e-03 Step 25/30: flux = 3.9491e-02, ||∇|| = 4.0018e-03 Step 26/30: flux = 3.9799e-02, ||∇|| = 3.2727e-03 Step 27/30: flux = 3.9897e-02, ||∇|| = 3.7567e-03 Step 28/30: flux = 3.9896e-02, ||∇|| = 4.0919e-03 Step 29/30: flux = 3.9947e-02, ||∇|| = 4.5817e-03 Step 30/30: flux = 4.0160e-02, ||∇|| = 4.4786e-03

Results Analysis¶

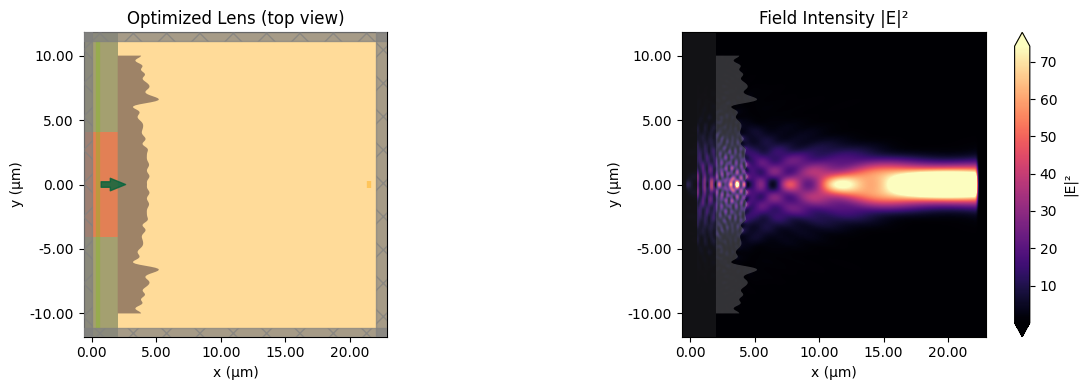

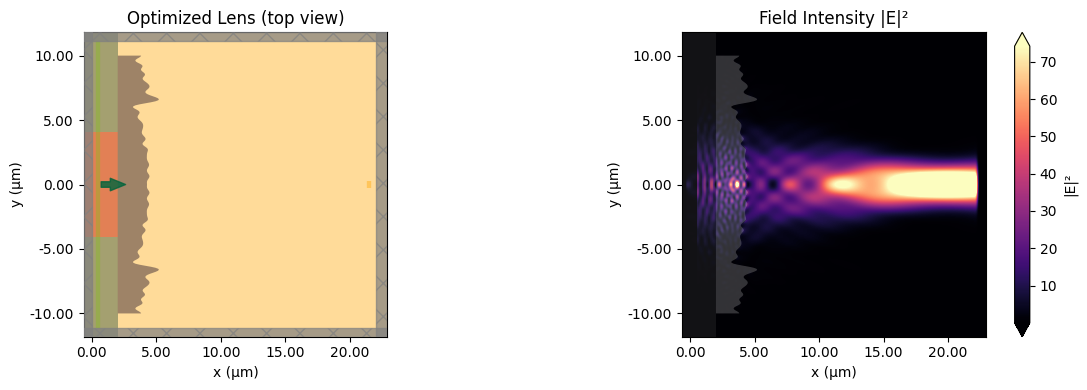

Let's analyze the optimization results by plotting the convergence history and visualizing the optimized lens alongside the field distribution. The optimized design typically exhibits a wave-like (Fresnel-like) surface profile that focuses light to the target region.

def plot_history(history):

"""Plot the optimization convergence history."""

plt.figure(figsize=(8, 4))

plt.plot(np.arange(1, len(history) + 1), history, "o-", linewidth=2, markersize=4)

plt.xlabel("Optimization Step")

plt.ylabel("Flux at Focal Plane")

plt.title("Optimization Convergence")

plt.grid(True, alpha=0.3)

plt.tight_layout()

plt.show()

def plot_design_and_field(sim, data):

"""Plot the lens geometry and field distribution side by side."""

f, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(12, 4))

sim.plot(z=0, ax=ax1)

ax1.set_title("Optimized Lens (top view)")

data.plot_field("field_z_0", "E", "abs^2", ax=ax2)

ax2.set_title("Field Intensity |E|²")

plt.show()

# Plot convergence

plot_history(history)

# Run final simulation with propagation monitor

final_sim = get_fiber_design_sim(params, monitor_propagation=True)

final_data = web.run(

final_sim, task_name="fiber_lens_final", verbose=False, path="fiber_lens_final.hdf5"

)

# Report final performance

final_flux = final_data["field_exit"].flux.values

print(f"\nFinal flux at focal plane: {final_flux.item():.4e}")

# Visualize results

plot_design_and_field(final_sim, final_data)

final_sim.plot_3d()

Final flux at focal plane: 4.0488e-02

Export Results¶

Finally, we save the optimized parameters and export the lens geometry as an STL file for fabrication or further analysis in CAD software.

# Save optimized parameters

np.save("fiber_lens_params.npy", get_static(params))

print(f"Saved {num_rings} optimized ring heights to 'fiber_lens_params.npy'")

# Export mesh as STL

mesh = mesh_from_params(params)

mesh.to_stl("fiber_lens.stl")

print("Exported lens geometry to 'fiber_lens.stl'")

Saved 128 optimized ring heights to 'fiber_lens_params.npy' Exported lens geometry to 'fiber_lens.stl'

Summary¶

In this notebook, we demonstrated inverse design of a fiber lens using Tidy3D's native autograd support. Key takeaways:

- TriangleMesh parameterization: Complex 3D surfaces can be optimized by making vertex positions differentiable

- Gaussian smoothing: Applying a smoothing kernel to parameters ensures manufacturable designs

- Adjoint efficiency: Gradients for 128 parameters are computed with just 2 simulations per step

- STL export: Optimized geometries can be directly exported for fabrication

Related Examples¶

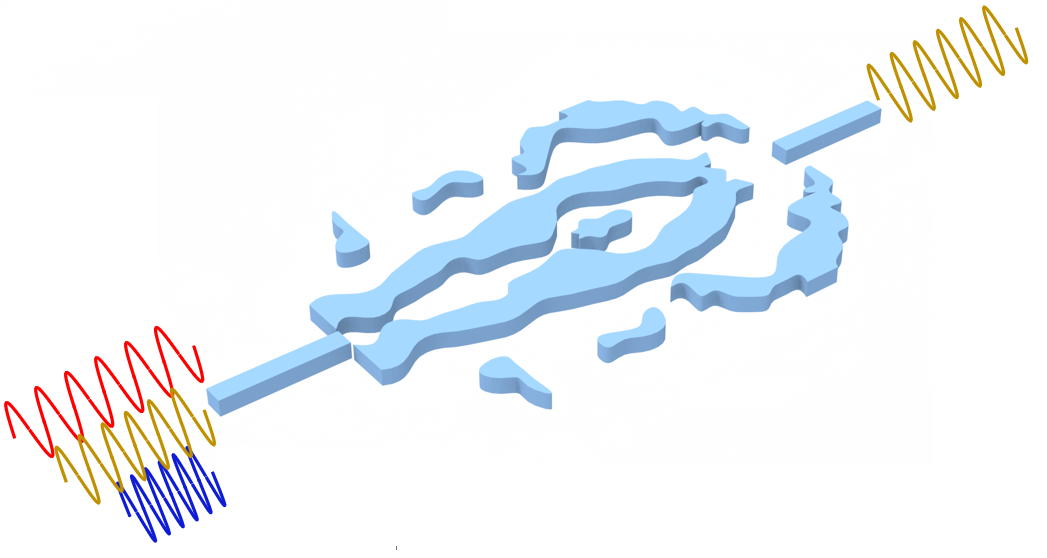

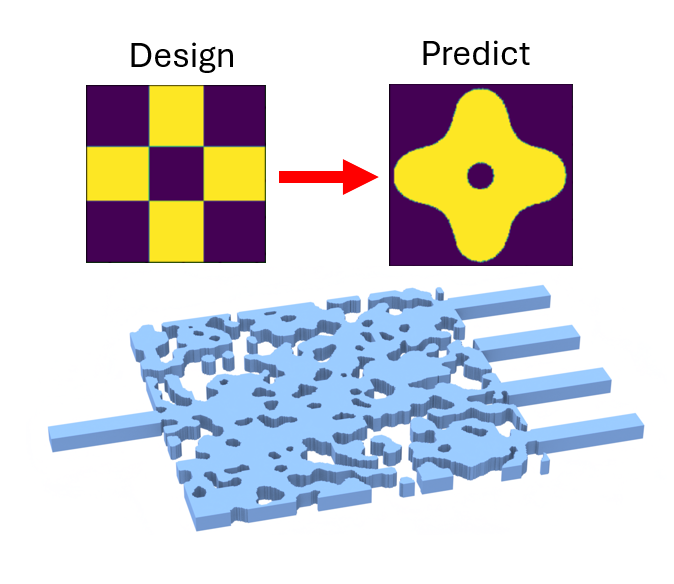

- Inverse Design Overview: Introduction to autograd in Tidy3D

- Metalens Optimization: Optimizing a flat metalens for focusing

- Grating Coupler: Inverse design of fiber-to-chip coupling

- Boundary Gradients: Shape optimization fundamentals