Beyond the Tunnel: Designing the A250 in the Age of Instant Aerodynamics

Wind tunnels have long been a cornerstone of aerospace engineering, providing direct measurements of forces and moments on physical models, with real-world fluid dynamics faithfully reproduced by nature itself. However, full-scale, production-ready models are often impractical to test—both due to cost and because, by that stage, it’s too late to meaningfully impact the design. While a well-executed wind tunnel campaign yields invaluable data, modern Computational Fluid Dynamics (CFD) offers powerful and complementary advantages.

With a tool like Flexcompute’s Flow360, we can simulate full-scale, state-of-the-art geometries quickly and accurately. Built for GPU-native performance, Flow360 enables us to run highly complex simulations in a matter of minutes—dramatically accelerating our design cycles. This speed and robustness allow for rapid result comparisons, deeper design confidence, and the creation of high-value aerodynamic performance databases critical for our flight controls and simulation teams.

Beyond forces and moments, CFD unlocks rich insights into the underlying physics of flight, providing a level of flow visualization that few other methods can match

Figure 1: BETA Technologies subscale A250 model

As a vertical takeoff and landing (VTOL) vehicle, the ALIA A250 must transition seamlessly between vertical and horizontal flight. This shift—from thrust-borne to wing-borne flight and back—creates complex aerodynamic interactions. Wake flows from the lifting propellers wash over the wings and impact downstream propellers, making it critical to capture and understand these effects with our computational tools.

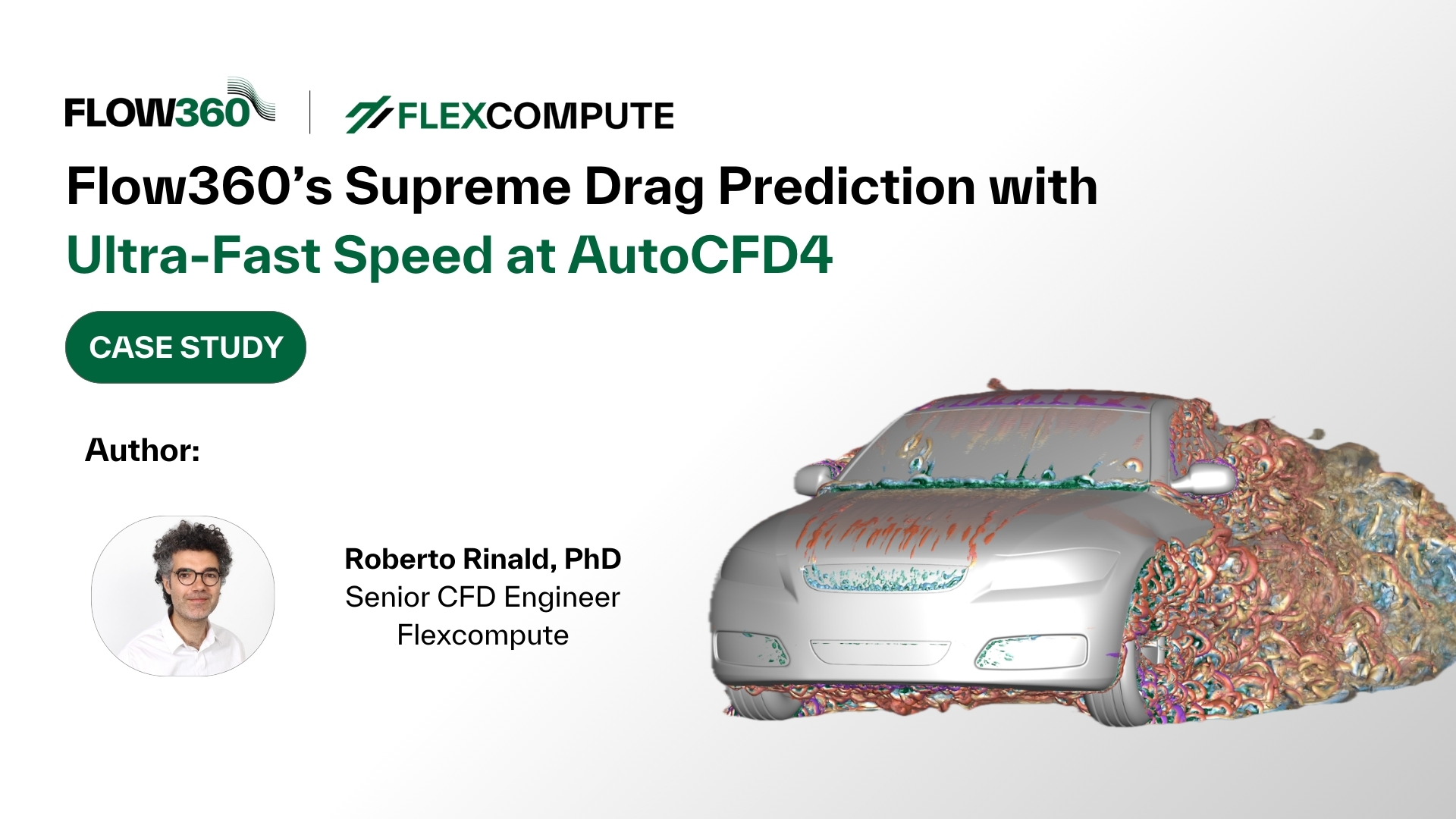

Wind tunnel testing clearly revealed aerodynamic interference between the lift propellers and the airframe, but it couldn’t fully visualize the underlying flow phenomena in the detail we wanted. By replicating key test points in CFD, we unlocked a deeper understanding of the flow physics—and demonstrated Flow360’s ability to accurately reproduce aerodynamic interactions and their impact on forces and moments.

Furthermore, CFD allows us to run the test points at full-scale Reynolds numbers, with production lift propellers and production geometry.

Figure 3: Time history of force and moment breakdown on various A250 components.

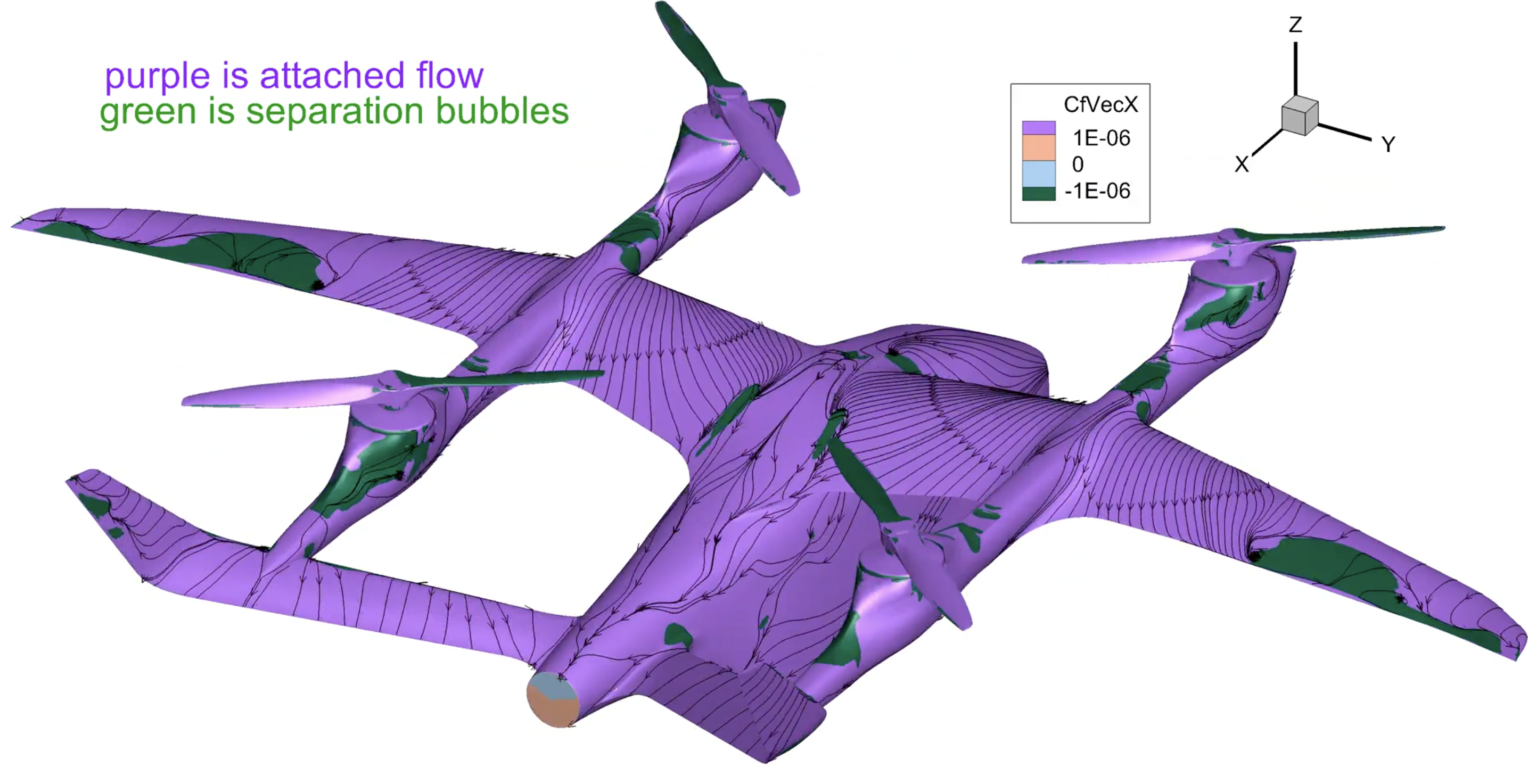

By breaking down forces and moments component by component, tracking their evolution over time as the propellers rotate, and combining this with:

● Surface skin friction visualizations

● Streamline flow data

● Q-criterion isosurfaces (to map vortex and downwash behavior)

We gain insights into some of the most aerodynamically interesting parts of the flight envelope, with much of the post-processing taken care of directly within Flow360.

Figure 4: Surface streamlines showing recirculation regions

Fig-5: Snapshot of Q-criterion isosurface revealing wake shedding

What Makes These Simulations So Challenging?

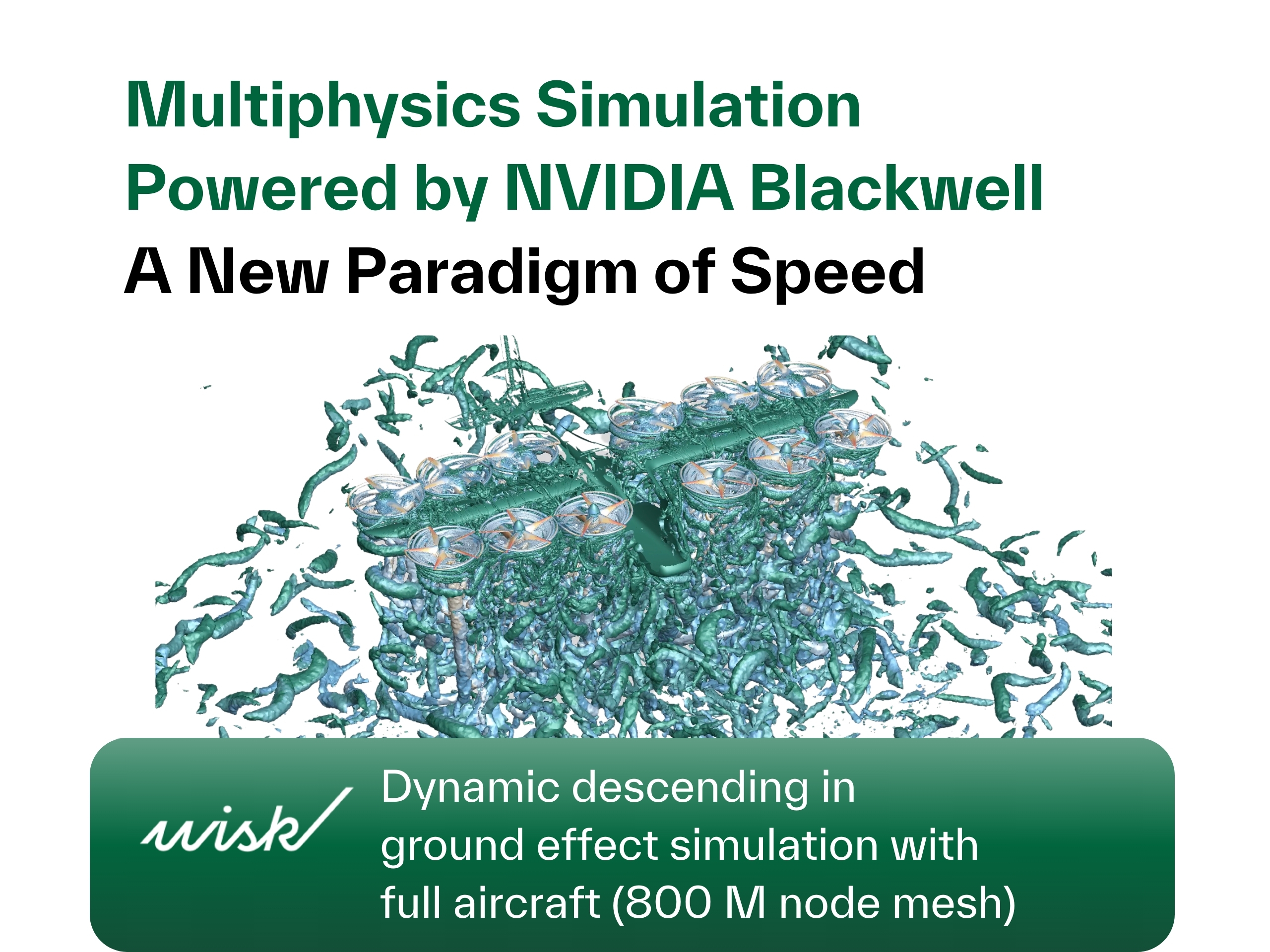

These CFD simulations are far from simple. They feature:

● Fast-spinning propellers, requiring small time steps to capture transient flow accurately

● Wake propagation, needing long simulation times to stabilize

● Highly refined mesh zones, particularly between interacting components, leading to massive mesh sizes—up to 119 million nodes

● Stringent accuracy demands, including many subiterations per time step to reach convergence by at least two orders of magnitude

● Advanced turbulence modeling, using the latest Spalart-Allmaras DDES implementation combined with low numerical dissipation algorithms

Fig-6: Slice through y=0 Symmetry plane showing volume mesh refinement regions.

Performance at the Cutting Edge

Flow360 enables us to run fully time-accurate DDES simulations with 119 million nodes—achieving under 7 minutes per propeller revolution using just 8 NVIDIA B-200 GPUs on Flexcompute hardware. That’s the speed and fidelity needed to drive real design decisions.

That’s speed and fidelity we can build on.

Why It Matters

Running these simulations early allows us to:

- Avoid costly redesigns

- Accelerate iteration cycles

- Deliver better, safer aircraft faster than ever before

With this level of insight, we can detect aerodynamic issues before a single part is manufacture, fixing them early in design or addressing them through flight control logic long before first flight. This predictive capability reduces rework, cuts cost and keeps us on schedule. CFD isn’t just a support tool anymore. It’s a core enabler of the next generation of flight.